In-situ compatibilization organic-inorganic hybrid membrane and preparation method

An in-situ compatibilizing, hybrid membrane technology, applied in the field of membrane separation, can solve the problems of difficult practical production, complex nanoparticle surface modification process, and increase the cost of membrane preparation, so as to reduce loss, improve mechanical properties and pressure resistance. Real performance and easy control of reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

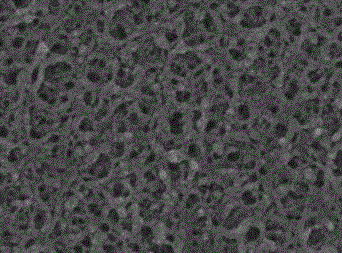

Image

Examples

Embodiment 1

[0039] Example 1: Polylactic acid-silica flat plate hybrid film

[0040] Polylactic acid was added to N,N-dimethylacetamide, dissolved at 60°C to obtain a polymer solution, and the surface aminated silica nanoparticles (particle size of 30 nm) were added to N,N-dimethylacetamide. In the amide, disperse uniformly under ultrasonic to obtain inorganic particle dispersion, mix the polymer solution and inorganic particle dispersion, react at 80 °C for 5 minutes, cool to 50 °C, and then add polyethylene glycol (molecular weight 400) as an additive, Fully stirring to obtain the casting liquid.

[0041] In the above composition, the mass fraction of polylactic acid is 15%, the mass fraction of silica is 0.5%, the mass fraction of N,N-dimethylacetamide is 69.5%, and the mass fraction of polyethylene glycol is 15%.

[0042] The casting liquid was scraped on a stainless steel plate, and a 30° C. N,N-dimethylacetamide aqueous solution (concentration of 15%) was used as a coagulation bath...

Embodiment 2

[0044] Example 2: Polylactic acid-silica hollow fiber hybrid membrane

[0045] Polylactic acid was added to dimethyl sulfoxide, then polyethylene glycol (molecular weight 400) was added as an additive, and the polymer solution was obtained by dissolving at 60 °C, and the surface aminated silica nanoparticles (particle size: 30nm) Add into dimethyl sulfoxide, disperse uniformly under ultrasonic to obtain inorganic particle dispersion, mix the polymer solution and inorganic particle dispersion, react at 60°C for 60 minutes, and cool to 30°C to obtain a casting solution.

[0046] In the above composition, the mass fraction of polylactic acid is 15%, the mass fraction of silica is 0.5%, the mass fraction of dimethyl sulfoxide is 69.5%, and the mass fraction of polyethylene glycol is 15%.

[0047] Take N,N-dimethylacetamide aqueous solution (concentration: 15%) at 40°C as the core liquid, N,N-dimethylacetamide aqueous solution (concentration: 5%) at 30°C as the outer coagulation ba...

Embodiment 3

[0049] Example 3: PET-Silica Flat Plate Hybrid Film

[0050] PET was added to N-methylpyrrolidone, dissolved at 90 °C, cooled to 60 °C to obtain a polymer solution, and surface aminated silica nanoparticles (particle size of 10 nm) were added to the polymer solution and ultrasonicated. Disperse uniformly, the temperature rises to 80 ℃ and reacts for 30 minutes, cools to 60 ℃, then adds polyvinylpyrrolidone (K30) as an additive, and fully stirs to obtain a casting liquid.

[0051] In the above composition, the mass fraction of PET is 16%, the mass fraction of silica is 0.01%, the mass fraction of N-methylpyrrolidone is 73.99%, and the mass fraction of polyvinylpyrrolidone is 10%.

[0052] The casting liquid was scraped on a glass plate, and water at 60°C was used as a coagulation bath to obtain a PET-silica flat plate hybrid film.

[0053] The surface contact angle of the modified membrane is 40 degrees, and the water flux at 0.1 MPa is 330 L / h / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com