A kind of modification method of water-resistant bone glue

A water-resistant, bone-adhesive technology, applied in the preparation of animal glue or gelatin, adhesives, adhesive types, etc., can solve problems such as development limitations, and achieve the effect of reducing the degree of sealing, enhancing the degree of adhesion, and improving the water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Mix bone glue particles and cold water at a mass ratio of 1:1.5 and place them in a three-necked flask, soak for 12-24 hours, and after fully swollen, heat up in a water bath to 65°C and stir at constant temperature for 20 minutes to dissolve to obtain a bone glue solution. Then add hydrochloric acid, hydrolyze at 65-70°C for 30 minutes to obtain a yellow translucent mucus, add sodium carboxymethylcellulose when the temperature drops to 40°C, react at a constant temperature for 90 minutes, add KH560 organosilane coupling agent, p-nitrophenol ethanol solution and stir at constant temperature After reacting for 40min, a yellow-brown viscous liquid was obtained; wherein the added hydrochloric acid accounted for 1% of the dry glue mass of the bone glue particles, the added sodium carboxymethylcellulose accounted for 3% of the dry glue quality of the bone glue particles, and the added KH560 organosilane The joint agent accounts for 3% of the dry glue mass of the bone glue par...

Embodiment 2

[0032] Mix bone glue particles and cold water at a mass ratio of 1:2 and place them in a three-necked flask, soak for 12-24 hours, and after fully swollen, heat up in a water bath to 60°C, stir at constant temperature for 35 minutes, and dissolve to obtain a bone glue solution. Then add citric acid, hydrolyze at 65-70°C for 180min to obtain yellow translucent mucus, add sodium carboxymethylcellulose when the temperature drops to 35°C, stir and react at constant temperature for 80min, add KH560 organosilane coupling agent and p-nitrophenol solution at constant temperature After stirring and reacting for 30 minutes, a yellow-brown viscous liquid was obtained; wherein the added citric acid accounted for 3% of the dry glue mass of the bone glue particles, the added sodium carboxymethylcellulose accounted for 2% of the dry glue quality of the bone glue particles, and the added KH560 organic The silane coupling agent accounts for 2% of the dry glue mass of the bone glue particles, an...

Embodiment 3

[0034] Mix bone glue particles and water at a mass ratio of 1:1.5 and place them in a three-necked flask, heat in a water bath to 70°C, stir at a constant temperature for 40 minutes, and dissolve to obtain a bone glue solution. Then add sulfuric acid, hydrolyze at 50°C for 60 minutes to obtain a yellow translucent mucus, add carboxymethylcellulose sodium at the same time, react for 70 minutes, add KH560 organosilane coupling agent, p-nitrophenol solution and stir for 60 minutes to obtain a yellow-brown viscous liquid The sulfuric acid added therein accounts for 1.5% of the dry glue quality of bone glue particles, the added sodium carboxymethylcellulose accounts for 4% of the dry glue quality of bone glue particles, and the added KH560 organic silane coupling agent accounts for 4% of the dry glue quality of bone glue particles. 2.5%, the added p-nitrophenol ethanol solution accounts for 6% of the dry glue mass of the bone glue particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

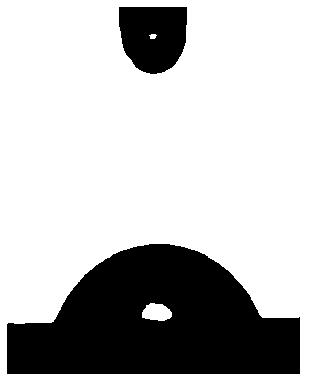

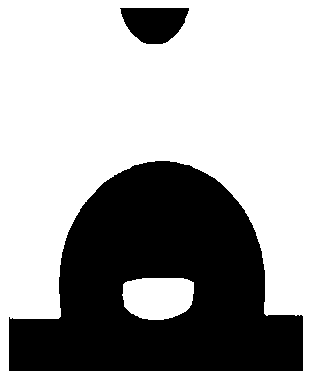

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com