Multi-element ion anti-microbial metallic coating

A multi-ion and antibacterial metal technology, which is applied in fireproof coatings, antifouling/underwater coatings, coatings, etc., can solve the problems of strong temperature dependence of antibacterial activity, affecting antibacterial effect, and decline in antibacterial activity, so as to improve antibacterial Sterilization performance, enhanced ionization activity and strength, and high antibacterial activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

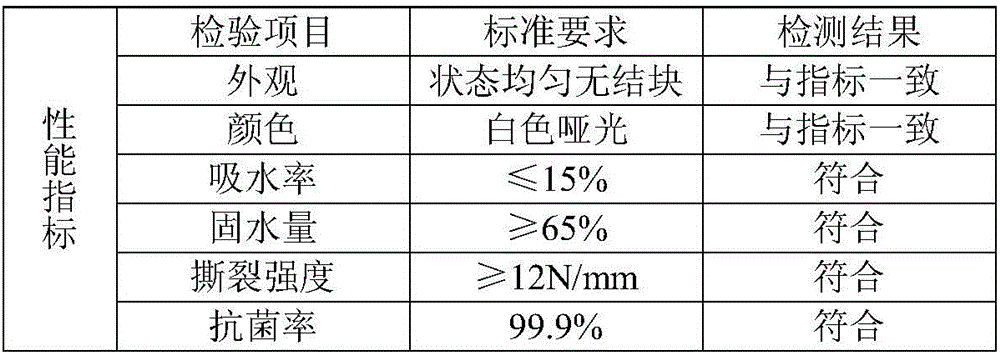

Examples

Embodiment 1

[0046] A kind of multi-ion antibacterial metal coating is made by following method:

[0047] (A) preparation of acrylic resin emulsion:

[0048] Weigh butyl acrylate, methyl acrylate, acrylonitrile, and acrylic acid monomers according to the mass ratio of 75:25:1:1 and mix them uniformly to obtain mixed monomers for later use; take acrylamide and toluene with a mass ratio of 1:1 Mix and stir, heat with a water bath at 40°C, and control the internal temperature of the solution to not be higher than 30°C. After the acrylic amine is completely dissolved, an aqueous solution of the crosslinking agent is obtained for use; the ammonium sulfate is dissolved in water 5 times its mass to obtain sulfuric acid Ammonium solution, spare.

[0049] Add 55g of distilled water and 165g of sodium lauryl sulfate into the reaction kettle, stir to dissolve, turn on the cooling water of the reflux condenser, and heat the kettle with steam. After the temperature in the kettle is stabilized at 80°C,...

Embodiment 2

[0059] A kind of multi-ion antibacterial metal coating is made by following method:

[0060] (A) preparation of acrylic resin emulsion:

[0061] Weigh butyl acrylate, methyl acrylate, acrylonitrile, and acrylic acid monomers according to the mass ratio of 70:30:0.5:0.5 and mix them evenly to obtain mixed monomers for later use; take acrylamide and toluene with a mass ratio of 1:0.5 Mix and stir, heat with a water bath at 45°C, and control the internal temperature of the solution to not be higher than 30°C. After the acrylic amine is completely dissolved, an aqueous solution of the crosslinking agent is obtained for use; the ammonium sulfate is dissolved in water four times its mass to obtain sulfuric acid Ammonium solution, spare.

[0062] Add 10g of distilled water and 100g of sodium lauryl sulfate into the reaction kettle, stir to dissolve, turn on the cooling water of the reflux condenser, and heat the kettle with steam. After the temperature in the kettle is stabilized at...

Embodiment 3

[0072] A kind of multi-ion antibacterial metal coating is made by following method:

[0073] (A) preparation of acrylic resin emulsion:

[0074] According to the mass ratio of 80:20:1.5:1.5, respectively weigh butyl acrylate, methyl acrylate, acrylonitrile, and acrylic acid monomers and mix them uniformly to obtain mixed monomers for later use; take acrylamide and toluene with a mass ratio of 1:1.5 Mix and stir, heat with a water bath at 45°C, and control the internal temperature of the solution to not be higher than 30°C. After the acrylic amine is completely dissolved, an aqueous solution of the crosslinking agent is obtained for use; the ammonium sulfate is dissolved in water six times its mass to obtain sulfuric acid Ammonium solution, spare.

[0075] Add 100g of distilled water and 300g of sodium lauryl sulfate into the reaction kettle, stir to dissolve, turn on the cooling water of the reflux condenser, and heat the kettle with steam. After the temperature in the kettle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com