High-speed friction cleaning device

A cleaning device, high-speed technology, applied in separation methods, filtration separation, biocides, etc., can solve problems such as limited flushing effect, and achieve the effect of enhancing ionization activity and strength, avoiding low antibacterial properties, and improving antibacterial performance and service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

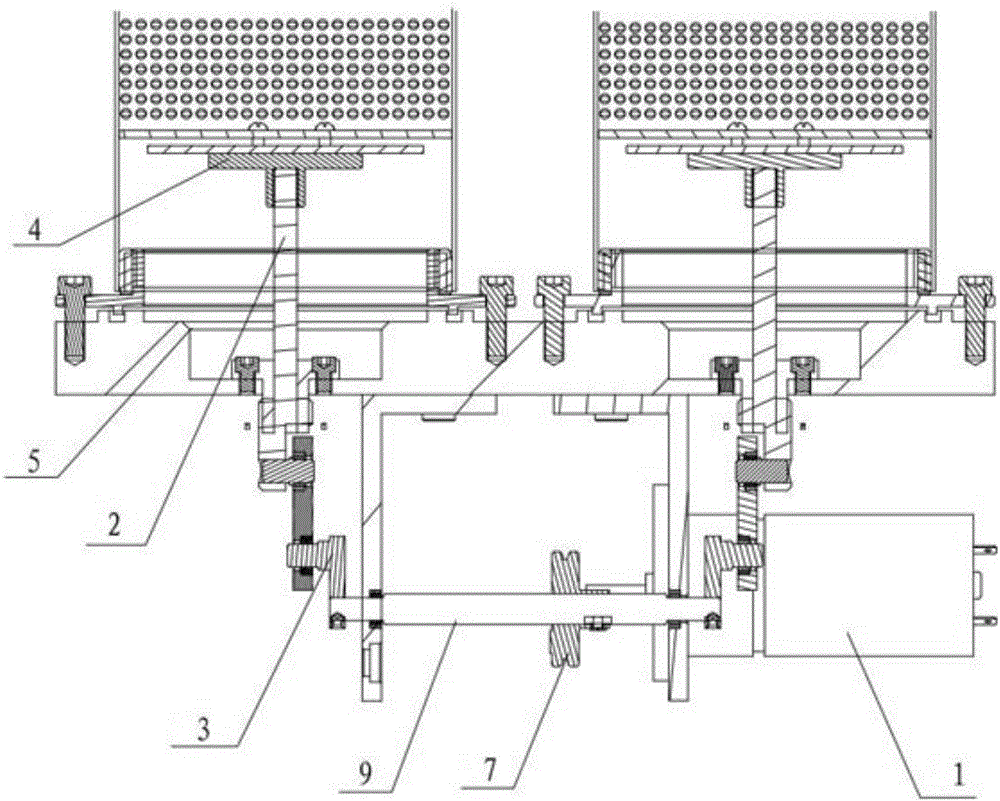

[0044] refer to figure 1 , a high-speed friction cleaning device, the cleaning device includes a motor 1, a transmission mechanism, two push rods 2, two cranks 3, two push plates 4 and two flanges 5; the cleaning device 1 and two purification The cartridge filter cartridges are connected, and the push plates 4 are respectively arranged in the purification cartridge filter cartridges and are used to support the cleaning ball; the push rod 4 vertically runs through the bottom of the purification cartridge filter cartridge, and the two ends of the push rod 2 are respectively connected to the push plate 4 and the Crank 3; crank 3 is connected to the transmission mechanism in transmission, and the transmission mechanism is connected to the motor in transmission; the flange 5 is arranged at the place where the push rod penetrates at the bottom of the purification cartridge filter cartridge.

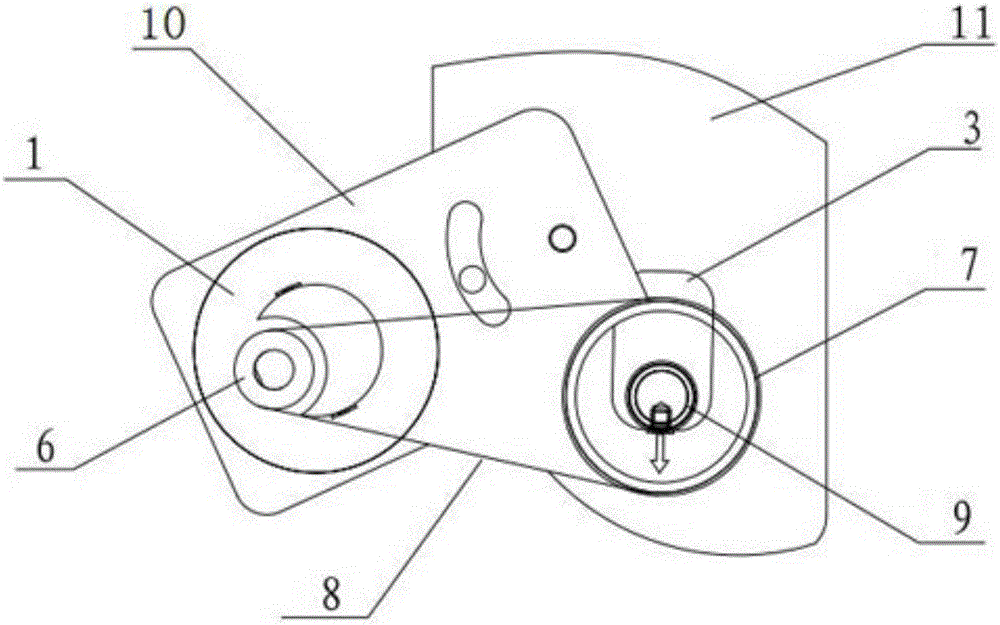

[0045] refer to figure 2 , the transmission mechanism is a belt transmission mechanism, i...

Embodiment 2

[0053] The difference between this embodiment and Embodiment 1 is that: the material of the cleaning ball is multi-ion antibacterial activated carbon.

[0054] Multi-ion antibacterial activated carbon is prepared from the following raw materials: activated carbon, silica powder, AgNO 3 , TiO2, Cu, Zn, Mg and deionized water;

[0055] The preparation steps of multi-ion antibacterial activated carbon are:

[0056] a) Weigh 28 parts of activated carbon and silica powder with a particle size of 200-400 mesh, add them to 240 parts of deionized water to prepare suspension A, and stir at 220r / min for 32min;

[0057] b) Weigh the AgNO which accounts for 2 / 3 of the total mass of activated carbon, activated carbon and silica powder respectively 3 , Cu powder, Zn powder, Mg powder, add deionized water to make 65 parts of suspension B, heat up to 90°C, stir at 800r / min for 50min, then add suspension B to the step at a speed of 30 drops / min a) In the obtained suspension A, obtain the su...

Embodiment 3

[0060] The difference between this embodiment and embodiment 1 is that the material of the cleaning ball is a mixture of activated silicon carbonate and medical stone.

[0061] The preparation steps of the mixture of activated silicon carbonate and medical stone are:

[0062] 1) Weigh 10 parts of AgNO each 3 , Cu(NO 3 ) 2 , added to 50-65 parts of deionized water, stirred at 80r / min for 22min, and adjusted to pH 4.3 to obtain an acidic liquid;

[0063] 2) Weigh 200 parts of silicon carbonate, rinse with water for 3-5 times, put them into containers respectively, add 400 parts of deionized water to soak for 72 hours; weigh 200 parts of medical stone, rinse with water for 3-5 times, and put them into another In the container, add 600 parts of deionized water to soak for 48 hours; after soaking, air-dry naturally, immerse in the acidic liquid obtained in step 1), and stir at 20r / min for 60min; after taking it out, put it into the activation furnace to heat up for activation, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com