Core/shell type nano-silver-based composite material as well as preparation method and antibacterial application thereof

A composite material and nano-silver technology, which is applied in the fields of application, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of easy aggregation of nano-silver, insufficient anti-oxidation, and poor antibacterial properties, and achieve good dispersion and excellent Antioxidant performance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

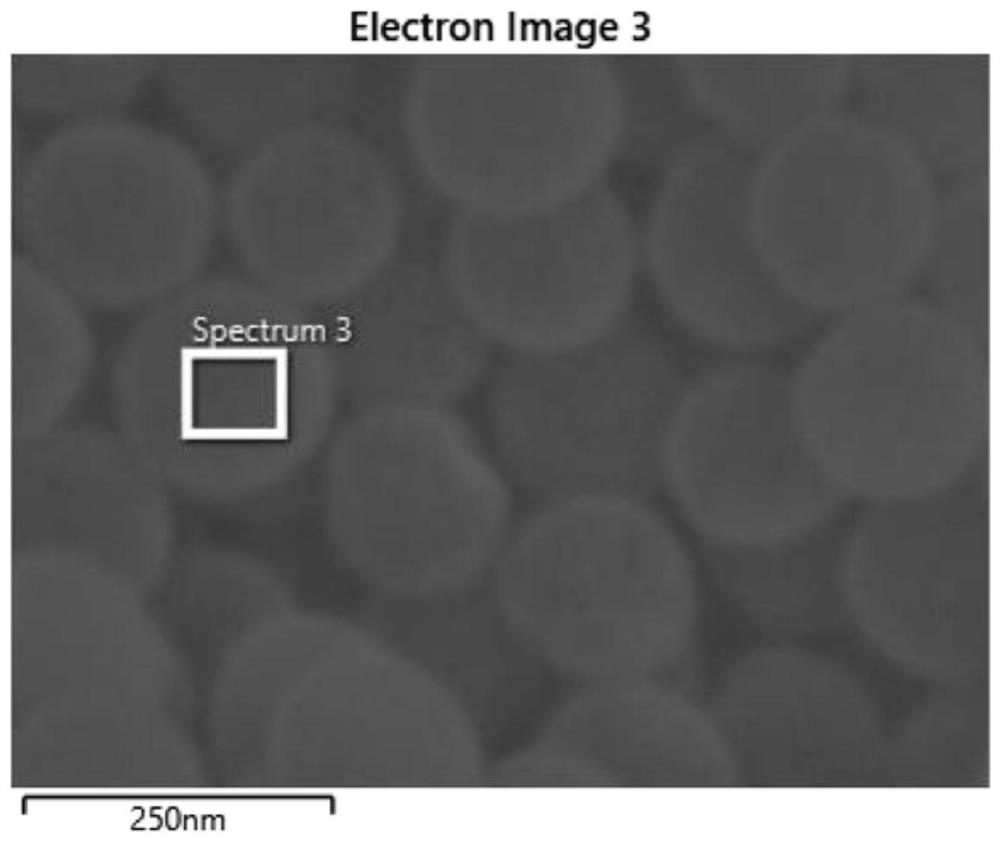

Image

Examples

Embodiment 1

[0041] Embodiment 1: The core / shell nano-silver matrix composite material provided in this example, its preparation method and antibacterial application, the core / shell type nano-silver matrix composite material is a spherical nano-cerium dioxide (n-CeO 2 ) as the substrate, the nano-silver is loaded on the spherical nano-ceria (n-CeO 2 ) surface to obtain nano-silver@ceria composites with silver loaded on the surface, namely core / shell nano-silver matrix composites, in which spherical nano-ceria (n-CeO 2 ) is prepared by the alcohol thermal method. Specific methods include:

[0042] 1) Add 2.0 g of cerium nitrate, 2 mL of deionized water, 2 mL of citric acid, and 0.5 g of polyvinylpyrrolidone to 52 mL of ethylene glycol, and stir for 30 min to obtain solution A;

[0043] 2) Transfer the solution A to the polytetrafluoroethylene lining, then load it into a stainless steel reactor and react at a high temperature of 180 ° C for 200 min, wait for the solution to be cooled to ro...

Embodiment 2

[0049] Embodiment 2: The core / shell nano-silver-based composite material and its preparation method and antibacterial application provided in this embodiment are basically the same as embodiment 1, and the differences are:

[0050] 1) 1.517g of cerium nitrate, 1.5mL of deionized water, 3.0mL of citric acid, 0.7g of polyvinylpyrrolidone, were added to 55mL of ethylene glycol, and stirred for 30min to obtain solution A;

[0051] 2) Transfer the solution A to the polytetrafluoroethylene lining, then load it into a stainless steel reactor and react at a high temperature of 120 ° C for 240 min, wait for the solution to be cooled to room temperature, pour off the upper yellow-brown clear liquid, and obtain a purple precipitate B;

[0052] 3) Transfer the precipitate B to a centrifuge bottle, wash it three times with distilled water and once with ethanol, and then put it into a 50° C. oven to dry, and obtain a precipitate C after drying is complete.

[0053] 4) Transfer the precipita...

Embodiment 3

[0055] Embodiment 3: The core / shell nano-silver-based composite material and its preparation method and antibacterial application provided by this embodiment are basically the same as embodiment 1, and the differences are:

[0056] 1) Add 1.5 g of cerium nitrate, 2 mL of deionized water, 2 mL of citric acid, and 0.4 g of polyvinylpyrrolidone to 50 mL of ethylene glycol, and stir for 30 min to obtain solution A;

[0057] 2) Transfer the solution A to the polytetrafluoroethylene lining, then load it into a stainless steel reaction kettle and react at a high temperature of 140 ° C for 200 min, wait for the solution to be cooled to room temperature, pour off the upper yellow-brown clear liquid, and obtain a purple precipitate B;

[0058] 3) Transfer the precipitate B to a centrifuge bottle, wash it three times with distilled water and once with ethanol, and then put it into a 60° C. oven to dry, and obtain a precipitate C after drying is complete.

[0059] 4) Transfer the precipit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com