Silkworm cocoon weighing and whitening powder as well as preparation method and use method thereof

A technology of whitening powder and whitening powder, which is applied in the field of silkworm medicine, can solve the problems of low solubility of methoprene, low product safety, and high transportation cost, and achieve the effects of increasing silkworm cocoon prices, low transportation costs, and obvious economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

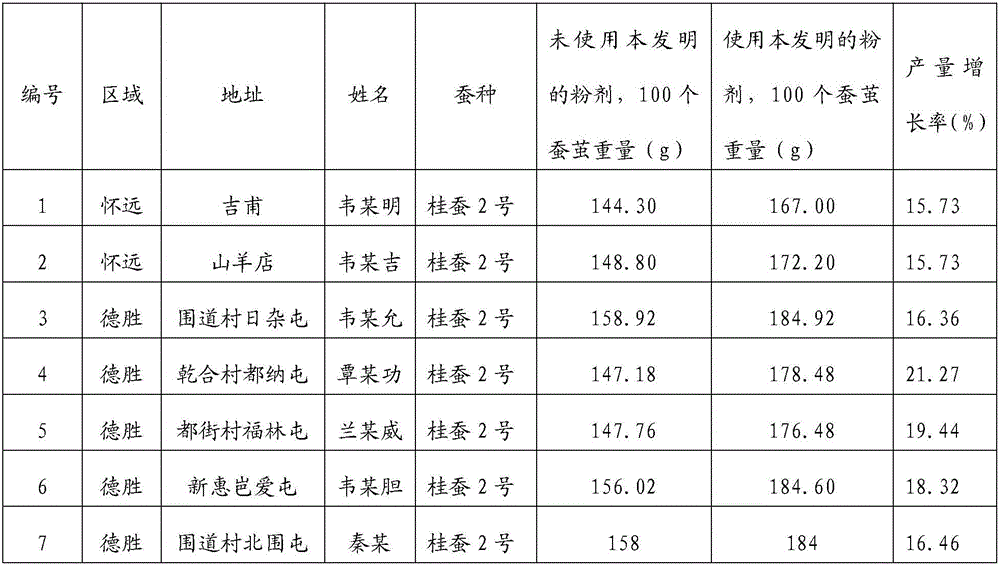

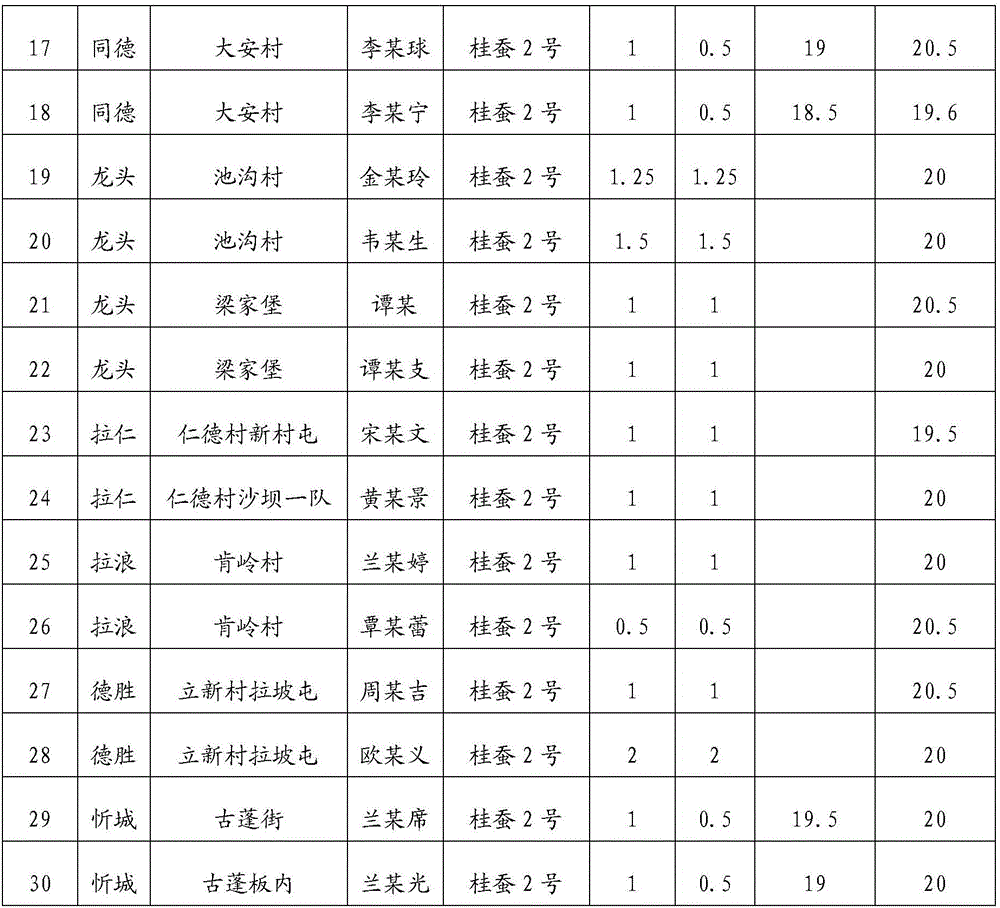

Examples

Embodiment 1

[0031] The cocoon weight gain and whitening powder of the present embodiment are made from brown sugar and methoprene emulsion in water, wherein the mass ratio of brown sugar and methoprene emulsion in water is 100:9, and in the water emulsion of methoprene The mass percentage of methoprene is 4%.

[0032] The preparation method of the above-mentioned cocoon weight gain and whitening powder comprises the following steps:

[0033] (1) making methoprene into a water emulsion of 4% by mass percent;

[0034] (2) Add brown sugar in the methoprene aqueous emulsion obtained in step (1), the mass ratio of the brown sugar to the methoprene aqueous emulsion is 100:9, dry at 45°C, and grind into 300 mesh powder, namely Obtain the silkworm cocoon weight gain and whitening powder.

[0035] The method for using the above-mentioned silkworm cocoon weight-increasing and whitening powder comprises the following steps: take 2.5 g of the above-mentioned silkworm cocoon weight-increasing and wh...

Embodiment 2

[0037] The silkworm cocoon weight gain and whitening powder of the present embodiment are made of white sugar and methoprene aqueous emulsion, wherein the mass ratio of the white sugar and methoprene aqueous emulsion is 100:16.5, and the methoprene aqueous emulsion is The mass percentage of methoprene is 4.2%, and the methoprene is S-methoprene.

[0038] The preparation method of the above-mentioned cocoon weight gain and whitening powder comprises the following steps:

[0039] (1) S-methoprene is made into water emulsion of 4.2% by mass percentage;

[0040] (2) add white sugar in the methoprene aqueous emulsion obtained in step (1), the mass ratio of the described white sugar and methoprene aqueous emulsion is 100:16.5, dry at 55 ℃, grind into 300 mesh powder, namely Obtain the silkworm cocoon weight gain and whitening powder.

[0041] The method for using the above-mentioned cocoon weight-increasing and whitening powder comprises the following steps: take 2.5 g of the abov...

Embodiment 3

[0043] The cocoon weight gain and whitening powder of the present embodiment are made from brown sugar and methoprene emulsion in water, wherein the mass ratio of brown sugar and methoprene emulsion in water is 100:18, and in the water emulsion of methoprene The mass percentage of methoprene is 4.5%, and the methoprene is S-methoprene.

[0044] The preparation method of the above-mentioned cocoon weight gain and whitening powder comprises the following steps:

[0045] (1) making S-methoprene water emulsion with mass percent as 4.5%;

[0046] (2) Add brown sugar to the methoprene aqueous emulsion obtained in step (1), the mass ratio of the brown sugar to the methoprene aqueous emulsion is 100:18, dry and grind at 65°C to obtain the silkworm cocoon Weight gain, whitening powder.

[0047] The method for using the above-mentioned silkworm cocoon weight-increasing and whitening powder comprises the following steps: take 2.5 g of the above-mentioned silkworm cocoon weight-increasi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com