Soluble cleansing paper with deep cleaning effect and preparation method thereof

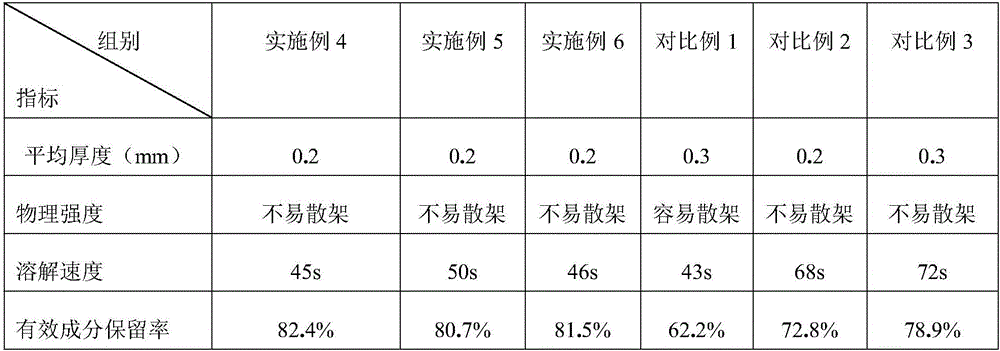

A soluble and cleansing paper technology, applied in skin care preparations, pharmaceutical formulations, cosmetic preparations, etc., can solve the problems of easy to fall apart, low retention rate of active ingredients, insufficient physical strength, etc., to improve physical strength and improve user experience. , The effect of improving the cleaning strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1, the preparation of soluble anionic starch of the present invention

[0040] S1) Enzymolysis: take pea starch, add 5% citric acid-disodium hydrogen phosphate buffer solution (pH7.0), stir in a boiling water bath to gelatinize, take it out, dilute to volume, and prepare a paste of 12-20 mg / ml Starch solution, oscillating in a constant temperature water bath at 50°C for 8 minutes, adding α-amylase, enzymatic hydrolysis for 60 minutes, and terminating the reaction to obtain starch enzymatic hydrolysis solution, which is set aside;

[0041] S2) Cross-linking: Add soybean oil, sodium hydroxide solution, Span-80 and epichlorohydrin to the above starch enzymatic hydrolysis solution, stir and mix, wherein, soybean oil, sodium hydroxide solution, Span-80 and epoxy The weight ratio of chloropropane is 1:1:0.2:0.5;

[0042] S3) Anionization: add ethanol solution, monochloroacetic acid, sodium hydroxide solution and the starch enzymatic solution treated in the above S...

Embodiment 2

[0044] Embodiment 2, the preparation of cationic nano-microcrystalline cellulose of the present invention

[0045] Take microcrystalline cellulose, crush it, pass through a 20-mesh sieve, add 150ml of 45wt% hydrochloric acid at 45°C, stir, react for 40min, add 9 times the volume of deionized water to dilute to terminate the reaction, and use deionized water to dilute the obtained product repeatedly. Centrifuge and wash to pH 5.0; put the obtained product into a dialysis bag, use flowing deionized water to dialyze the paper to a constant pH value, and treat the dialyzed suspension with an ultrasonic oscillator for 10 minutes to obtain nanocrystalline cellulose suspension liquid, in order to avoid product aggregation due to heat, the treatment is carried out in a hot water bath;

[0046] Add phosphate buffer solution to the above-mentioned nano-microcrystalline cellulose suspension to obtain a mass concentration of 5% nano-microcrystalline cellulose suspension, add sodium hydrox...

Embodiment 3

[0047] Embodiment 3, preparation of chicory inulin hydrolyzate according to the present invention

[0048] Weigh chicory root coarse powder, add purified water twice the weight of the coarse powder, extract twice at 80°C for 2 hours each time, filter, combine the extracts, concentrate the extracts under reduced pressure to 60°C, and measure the relative density 1.15 extract, pulverized, and spray-dried to obtain chicory polysaccharide; take the above-mentioned chicory polysaccharide and add 5% hydrochloric acid solution to mix at a ratio of 1:1, stir to obtain a starch polysaccharide solution, and place the above starch polysaccharide solution at a constant temperature of 40°C React in a water bath for 2 hours, keep stirring during the reaction, and the stirring speed is 2000rpm, that is to say.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com