Polyolefin microporous film and method for manufacturing same, separator for nonaqueous electrolyte secondary cell, and nonaqueous electrolyte secondary cell

A non-aqueous electrolyte and microporous membrane technology, which is applied in the field of polyolefin microporous membranes, can solve the problems of improving the pore size and making it difficult to take into account the shutdown characteristics, the safety cannot be obtained, and the pore size becomes larger, so as to suppress dendrites The generation and growth, strength and safety are excellent, and the effect of small pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

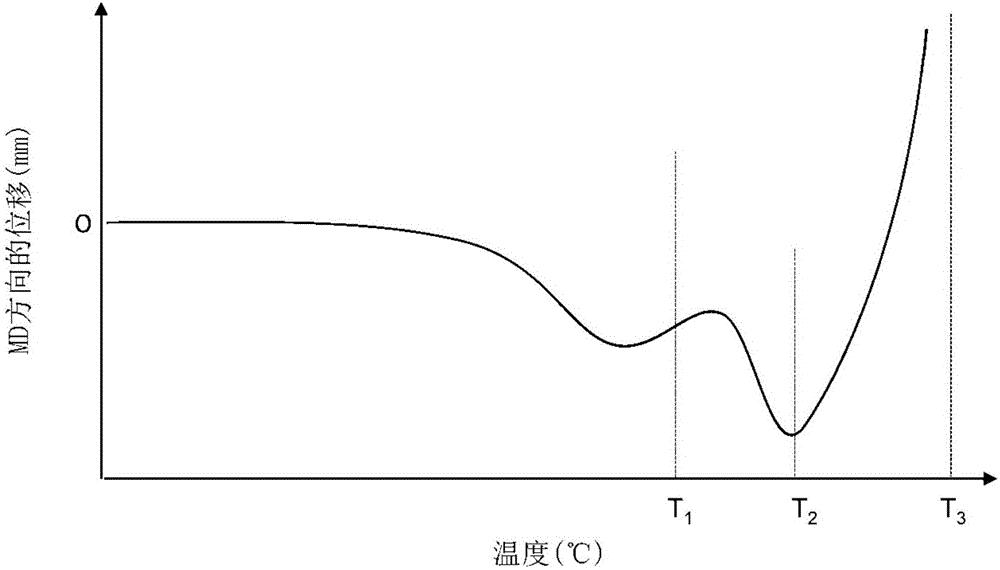

Method used

Image

Examples

Embodiment 1

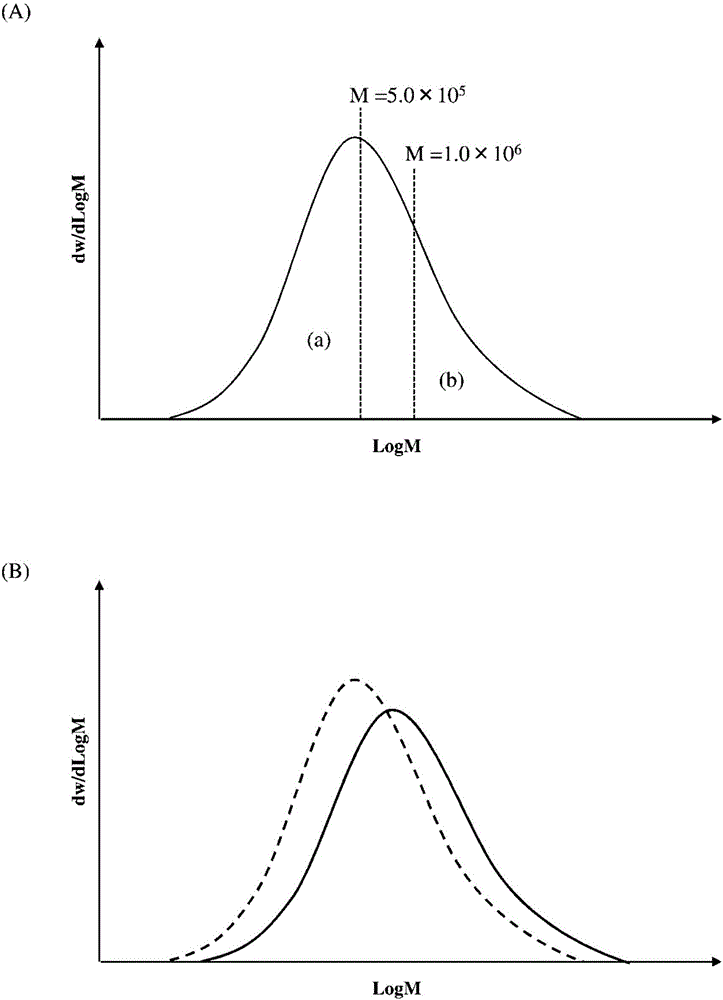

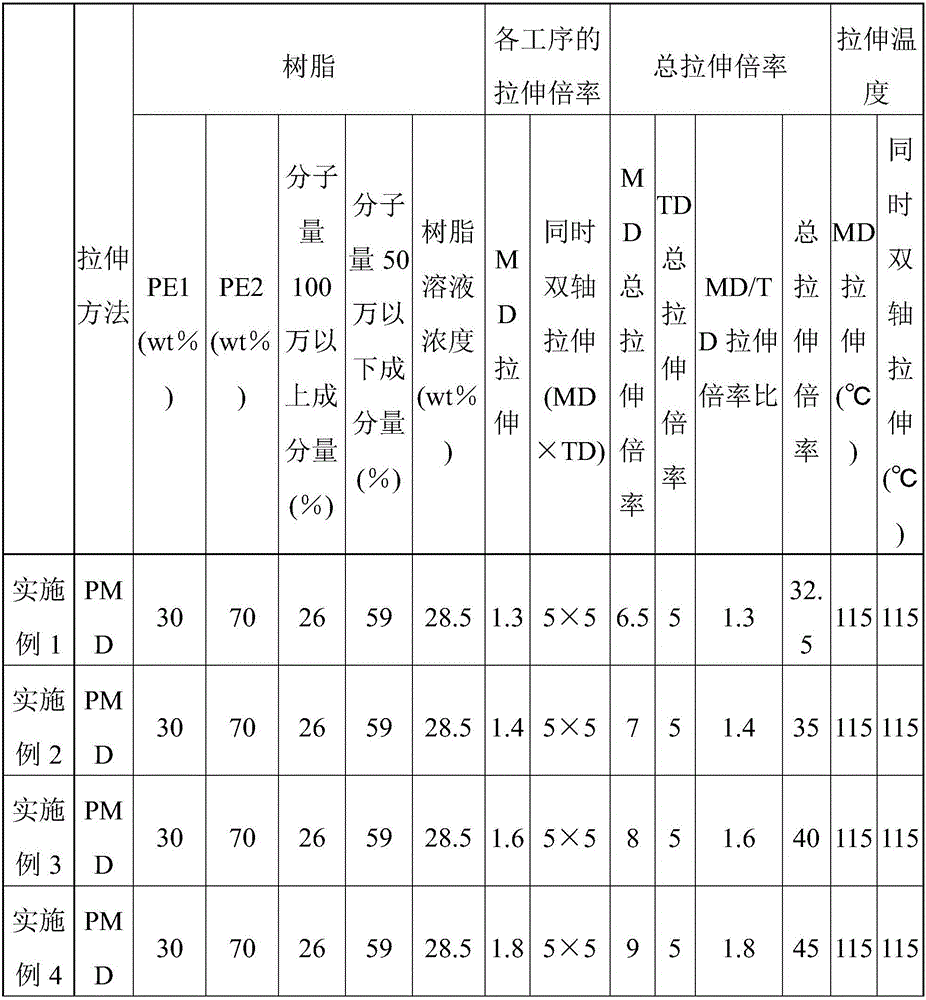

[0134] PE1 (ultra-high molecular weight polyethylene, weight average molecular weight (Mw): 2.89×10 6 , molecular weight distribution (Mw / Mn): 5.28) 30% by weight and PE2 (high-density polyethylene, weight-average molecular weight: 5.72×10 5, Molecular weight distribution: 4.81) 70% by weight formed polyethylene composition. When the whole polyethylene composition was 100% by weight, the content of the polyethylene component with a molecular weight of 500,000 or less was 59% by weight, and the content of the polyethylene component with a molecular weight of 1,000,000 or more was 26% by weight. Add 71.5% by weight of liquid paraffin to 28.5% by weight of the polyethylene composition, further, based on the mass of polyethylene in the mixture, add 0.5% by mass of 2,6-di-tert-butyl-p-cresol and 0.7% by mass % tetrakis[methylene-3-(3,5-di-tert-butyl-4-hydroxyphenyl)-propionate]methane was used as an antioxidant and mixed to prepare a polyethylene resin solution. This polyethylene...

Embodiment 2

[0136] A polyolefin microporous membrane was produced in the same manner as in Example 1 except that the draw ratio in the MD stretching step was 1.4 times. Tables 1 to 3 show the membrane properties of the obtained polyolefin microporous membrane.

Embodiment 3

[0138] A polyolefin microporous membrane was produced in the same manner as in Example 1 except that the draw ratio in the MD stretching step was 1.6 times. Tables 1 to 3 show the membrane properties of the obtained polyolefin microporous membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com