Drill and drill head

A drill bit and head technology, which is applied in the field of drill bits and drill bit heads, can solve the problems of high cutting resistance, short tool life, and inability to fully ensure the amount of regrinding, and achieve the effects of improving processing efficiency and suppressing cutting resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach >

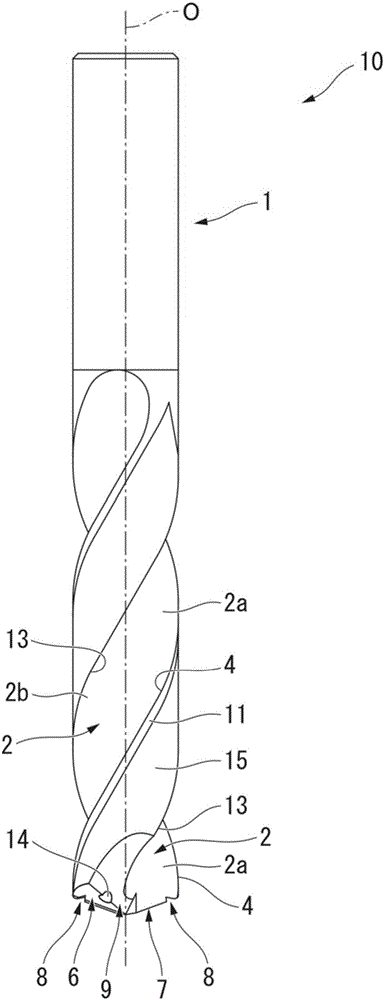

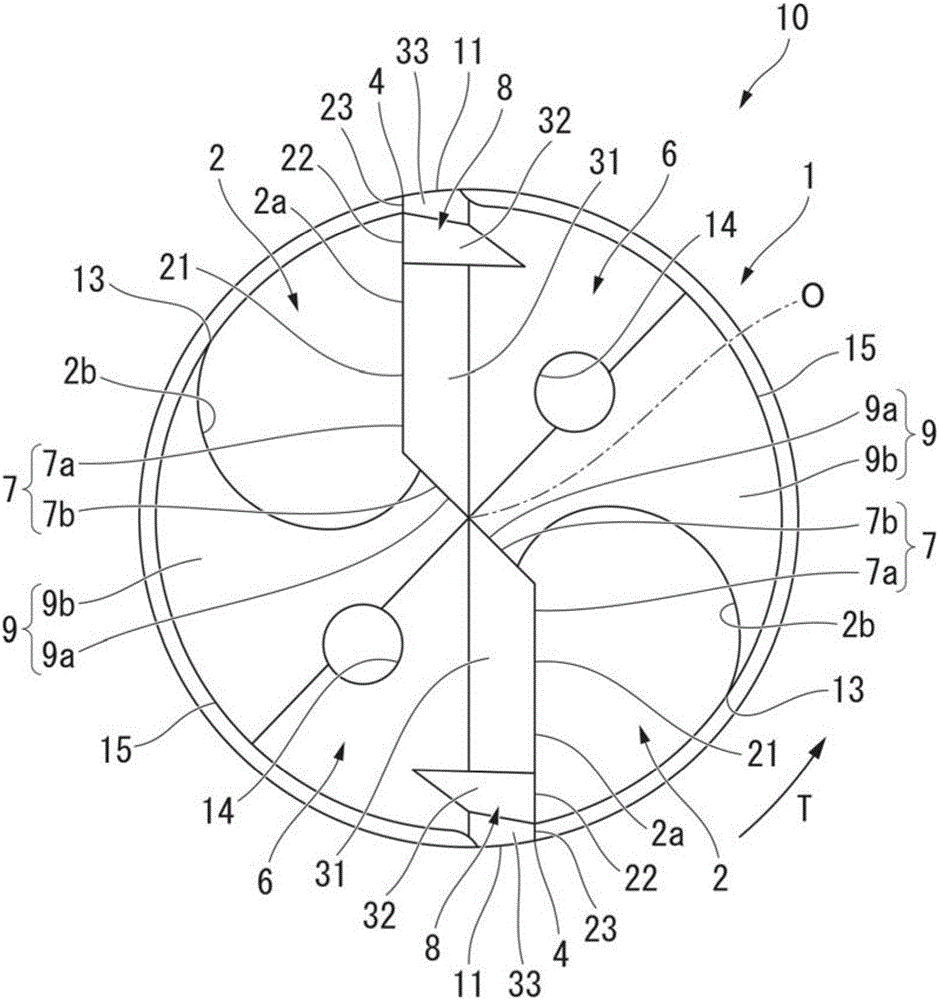

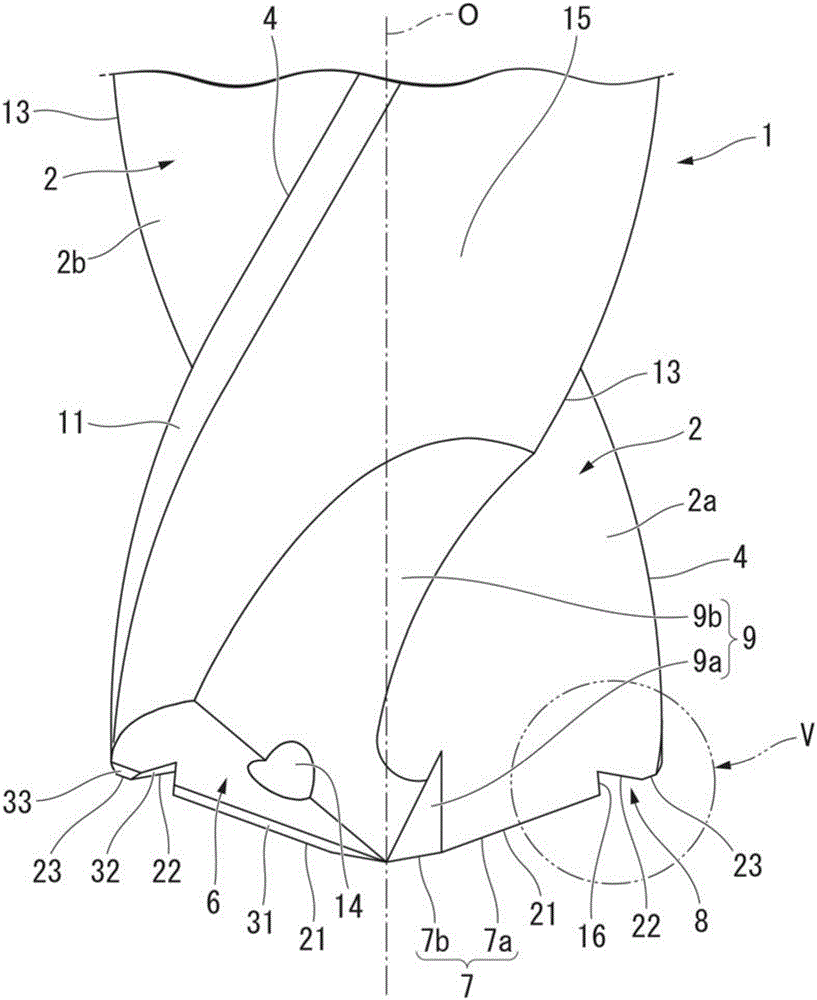

[0164] Below, refer to Figure 1 to Figure 6 The drill 10 according to the first embodiment of the present invention will be described.

[0165] like Figure 1 ~ Figure 4As shown, the drill 10 of the present embodiment has a drill body 1 having a substantially cylindrical shape centered on an axis O and formed of a hard material such as cemented carbide. The base end side portion in the axis O direction of the drill body 1 is a cylindrical shank, and the front end side portion in the axis O direction is a blade portion having a cutting edge. In addition, the cutting edge includes a front end edge 7 and an outer peripheral edge 4 which will be described later.

[0166] In the drill 10, the shank of the drill body 1 is detachably mounted on the spindle of the machine tool or the three-jaw chuck of the drill press and electric drill, etc., and rotates along the drill rotation direction T around the axis O, and moves to the front end along the axis O direction. side( figure 1...

no. 2 Embodiment approach >

[0274] Next, refer to Figure 11 to Figure 15 , the drill 30 according to the second embodiment of the present invention will be described.

[0275] In addition, the detailed description of the same constituent elements as those of the first embodiment described above will be omitted, and only the differences will be mainly described below.

[0276] The drill 30 of the present embodiment is provided with a fourth front edge 24 instead of the ridge line 16 described in the aforementioned drill 10 , which constitutes a part of the front edge 7 and functions as a cutting edge. Furthermore, the shape of the recessed portion 38 is different from the shape of the recessed portion 8 described in the first embodiment by forming the fourth front end edge 24 , and the fourth flank 34 is formed in the recessed portion 38 of the present embodiment.

[0277] Specifically, in this embodiment, if Figure 12 to Figure 15 As shown, the radial inner end of the second front end cutting edge 22...

no. 3 Embodiment approach >

[0379] Next, refer to Figure 22A ~ Figure 25 , the drill 60 according to the third embodiment of the present invention will be described.

[0380] In addition, in the following, the detailed description of the same constituent elements as those of the aforementioned reference example will be omitted, and only the differences will be mainly described.

[0381] [Differences from the above reference example]

[0382] The main difference between the drill 60 of this embodiment and the drill 50 described in the aforementioned reference example lies in the shape of the tip of the drill body 1 (the tip surface 26 , the tip edge 17 ).

[0383] 〔Front side〕

[0384] Figure 22A and Figure 22B In the shown drill 60 of this embodiment, the front end surface (front flank) 26 of the drill body 1 is provided with a first relief surface 31 , followed by a first front edge 21 to a first front edge 21 described later from the front end edge 17 . 4. Among the front end cutting edges 24, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com