Method for producing D-ribose at high yield by using bacillus subtilis engineering bacterium

A Bacillus subtilis, engineering bacteria technology, applied in the field of bioengineering, can solve the problems of large infection risk, poor tolerance, slow growth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

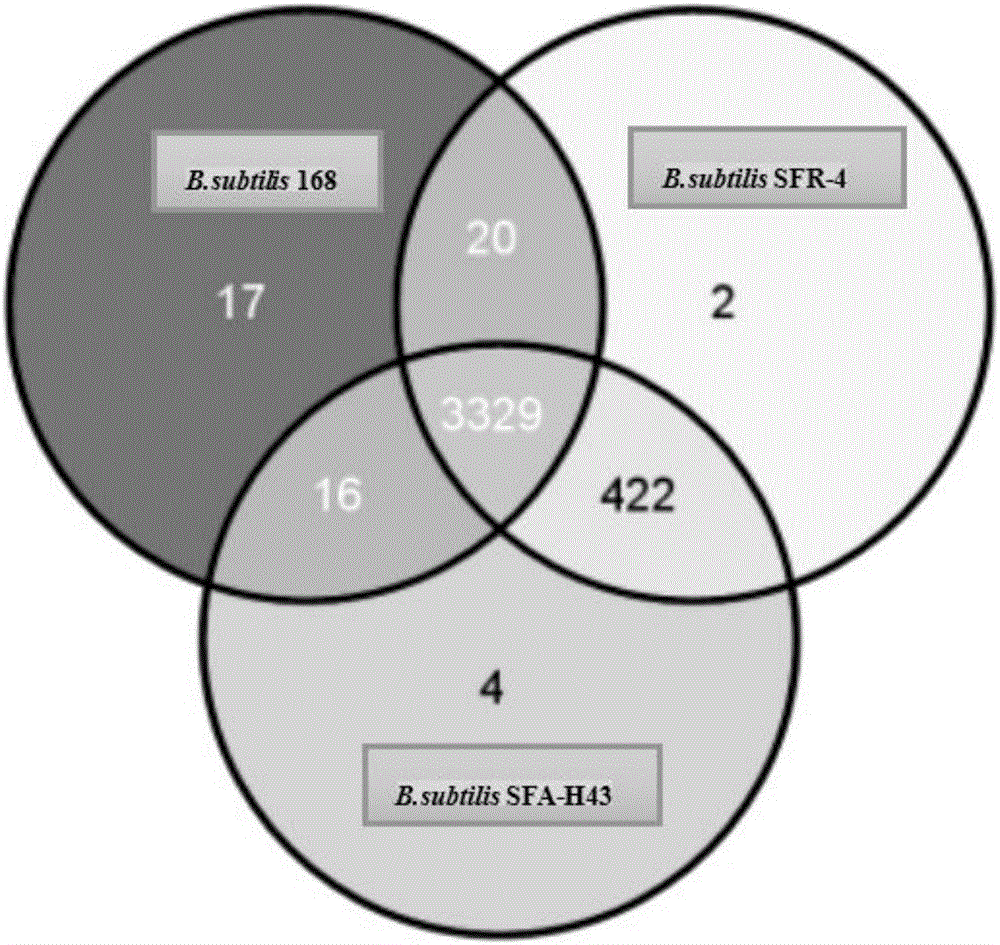

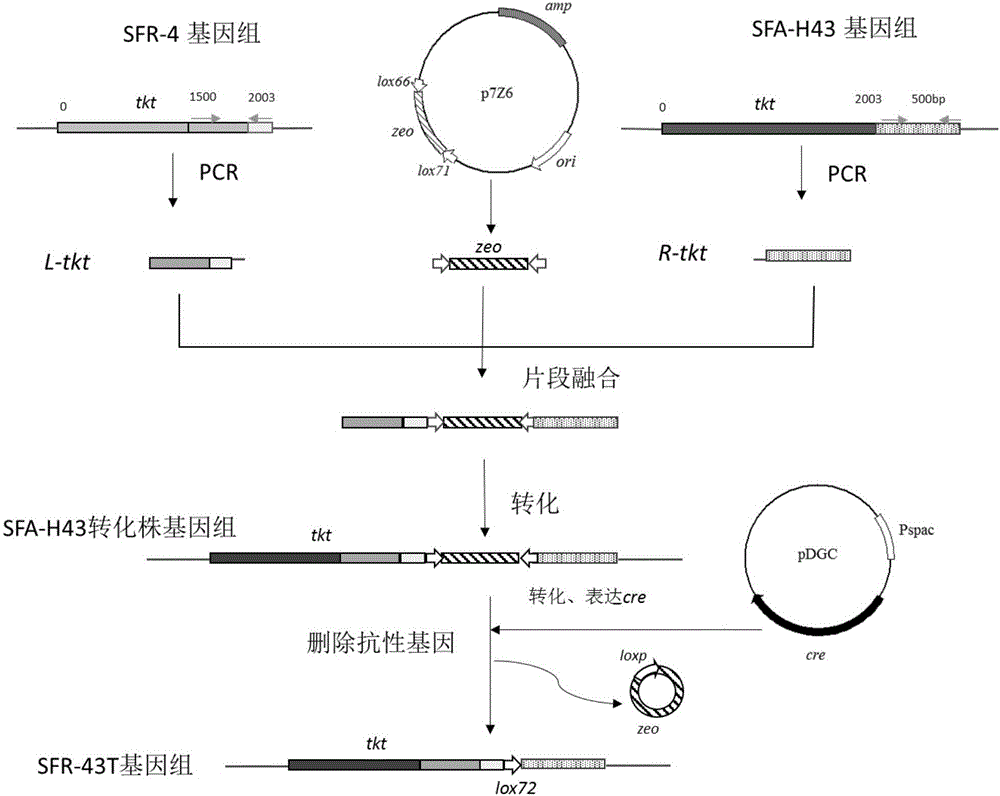

[0058] Example 1 strain SFR-43T construction

[0059] (1) Using the strain SFR-4 genome as a template, amplify the 500 bp fragment (including the mutation site) before the stop codon of the transketolase gene of the strain, called L-tkt (its sequence is shown in SEQ ID NO.10) . Its downstream primer contains the front 25bp complementary sequence of lox71-zeo-lox66.

[0060] Template: strain SFR-4 genome

[0061] Upstream primer: GCAGCATGGAAGCTTGCAG (SEQ ID NO.1)

[0062] Downstream primer: TATAATGTATGCTATACGAACGGTATTATCTTGATACTATAG AAACATCTCAAGG (SEQ ID NO.2)

[0063] PCR reaction system (50uL): strain SFR-4 genomic DNA template 1uL, upstream primer 1uL, downstream primer 1uL, 2*Buffer 25uL, dNTP 4uL, high-fidelity PCR enzyme PrimeSTAR 0.5uL, sterile water 17.5uL.

[0064] PCR reaction conditions: denaturation at 95°C for 5min, 10s at 98°C, 30s at 60.3°C, 30s at 72°C, 33 cycles.

[0065] The amplified products were detected and collected by 1% agarose gel electrophoresis....

Embodiment 2

[0095] Embodiment 2 bacterial strain SFR-43T product analysis

[0096] Take the fresh slant of the strain SFR-43T cultured at 37°C for 2 days, use an inoculation loop to take 1-2 loops of the slant strain, inoculate it into the liquid seed medium, cultivate it on a shaker at 37°C for 14 hours at 180rpm, and inoculate 5% of the inoculum. Into the fermentation medium, 37 ° C, 180 rpm shake flask culture for 72 hours. The fermentation broth was centrifuged at 4500rpm for 10min, and the supernatant was taken for product analysis. The results showed that 3-hydroxybutanone and D-ribose components were detected simultaneously in the fermentation broth of the strain SFR-43T.

[0097] Fermentation medium (g / L): glucose 150g / L, yeast extract 5g / L, corn steep liquor 10g / L, (NH 4 ) 2 SO 4 2.5g / L, MgSO 4 2g / L, MnSO 4 0.2g / L, pH6.5.

Embodiment 3

[0098] Embodiment 3 fermentation medium optimization

[0099] Based on the strain SFR-4D-ribose fermentation medium, the present invention further optimizes the nitrogen source and other components of the culture medium for the fermentation of D-ribose by the strain SFR-43T.

[0100] Nitrogen source optimization: take fresh slant of the strain SFR-43T cultivated at 37°C for 2 days, pick 1-2 rings with an inoculation loop, inoculate into liquid seed medium, culture at 37°C, 180rpm shaker for 14 hours, inoculum amount 5% , inoculated into shake flask fermentation media containing different nitrogen sources (the nitrogen sources were respectively peptone, yeast extract, corn steep liquor dry powder, ammonium nitrate, diammonium hydrogen phosphate, ammonium sulfate, the concentration was 10g / L, and the carbon source was Glucose, the other components are the same), 37 ° C, 180 rpm shake flask culture for 72 hours. The fermentation broth was centrifuged to remove bacteria, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com