Sterile air-permeable sealing film structure for microbe culture bottle

A microbial culture and sealing film technology, applied in enzymology/microbiology devices, biomass post-treatment, biomass pre-treatment, etc., can solve the problems of occupying the inner and outer space of the bottle mouth, the air holes do not correspond, and the culture pollution, etc., Achieve the effects of increasing the number of reusable times, improving the fixing effect, and ensuring the filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

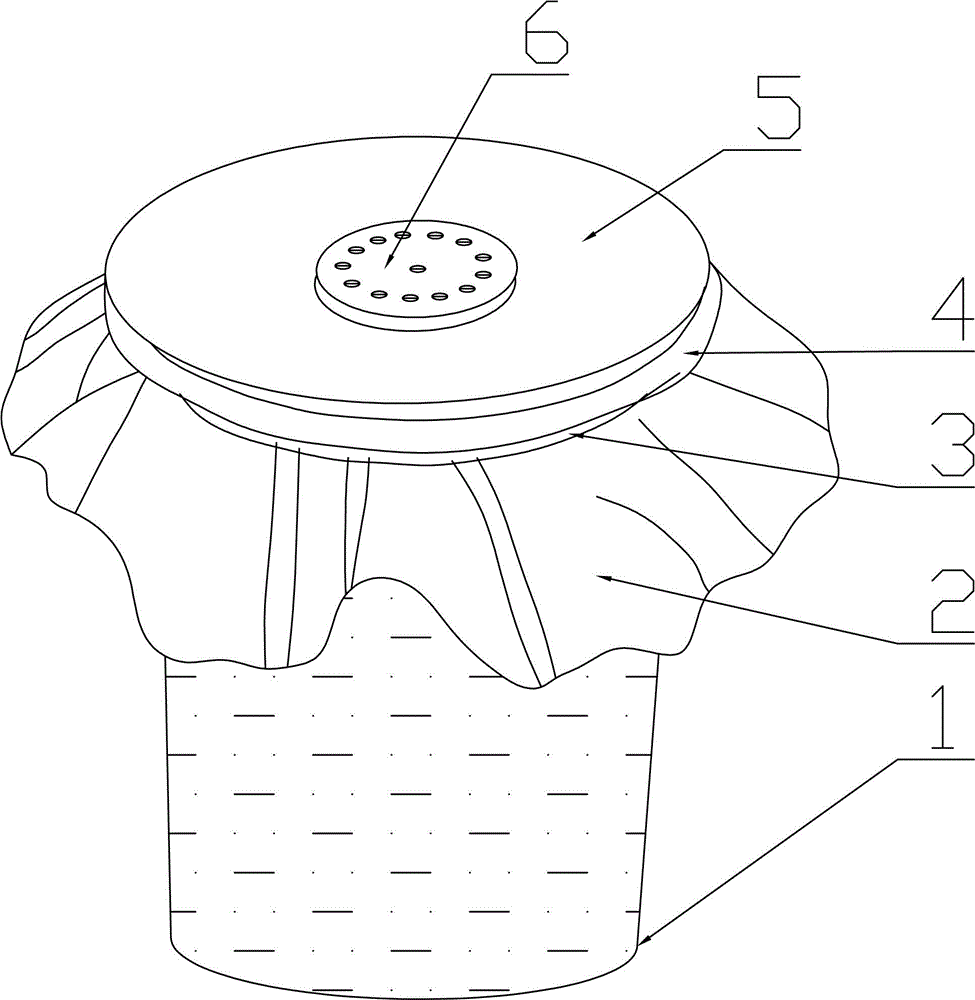

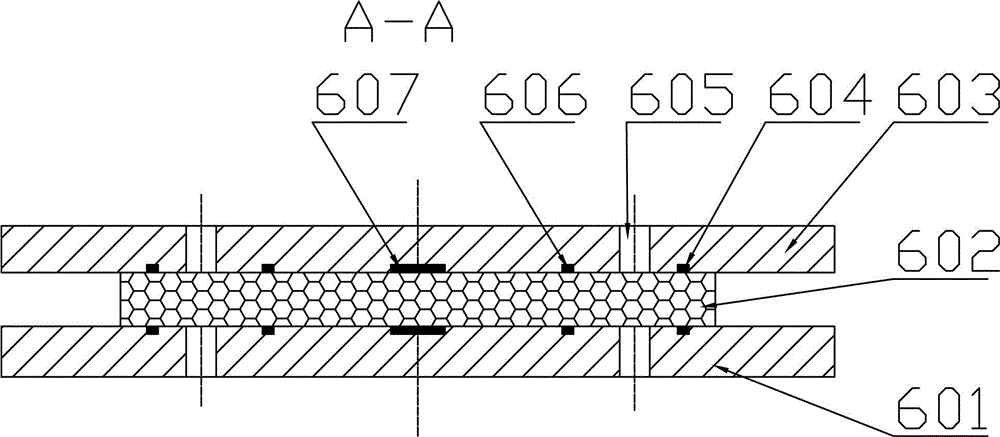

[0017] join Figure 1-3 , a sterile air-permeable sealing film structure for a microbial culture bottle, which includes an adapted culture bottle 1, the top of the culture bottle 1 is provided with a bottle mouth 4, and the bottle mouth 4 of the culture bottle 1 is bound with a plastic film 2 through a cable tie 3, and the bottle The opening of the mouth 4 is provided with a bottle mouth seal 5, and the central position of the bottle mouth seal 5 is provided with a sealing film ventilation window structure 6, and the sealing film ventilation window structure 6 includes a bottom film 601 and a top film 603, and the bottom film 601 and the top layer A filter medium 602 is arranged between the films 603, and the center position of the upper and lower surfaces of the filter medium 602 is fixedly connected with the bottom film 601 and the top film 603 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com