Organic-inorganic hybrid perovskite quantum dot and preparation method thereof

A perovskite and quantum dot technology, applied in chemical instruments and methods, nanotechnology, nano-optics, etc., can solve the problem of poor stability of quantum dots, easy decomposition, and restrictions on the industrial application of organic-inorganic hybrid perovskite quantum dots, etc. problem, to achieve the effect of stabilizing luminous performance, improving stability, and improving water and oxygen stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] Correspondingly, the present invention also provides a method for preparing organic-inorganic hybrid perovskite quantum dots, comprising the following steps:

[0043] Using siloxane with amino-terminated siloxane as a ligand, mix it with a transition metal halide and an organic amine compound in a first solvent to form a precursor solution; the first solvent is DMF, dimethyl sulfoxide, THF, acetonitrile or acetone; the organic amine compound is methyl ammonium halide or phenethylamine halide;

[0044] The precursor solution is mixed with a second solvent, and precipitation occurs in a non-airtight state to obtain organic-inorganic hybrid perovskite quantum dots with a silicon dioxide layer on the surface; the second solvent is toluene, chloroform, n-hexane, Cyclohexane, ethyl acetate or ether.

[0045] Through the optimized production process and other contents of the embodiments of the present invention, a hybrid perovskite quantum dot material with a single emission ...

Embodiment 1

[0065] 1mmol PbBr 2 , 0.8 mmol CH 3 NH 3 Br and 1.38mmol APTS were miscible in DMF, and the resulting mixed solution was injected into rapidly stirring toluene, resulting in precipitation, and a solution sample of organic-inorganic hybrid perovskite quantum dots was obtained.

[0066] Stir the solution sample for 2 hours, then centrifuge (3000rpm, 15min), add ethanol, stir and centrifuge (3000rpm, 15min), dry at 50°C, grind the dried solid to obtain 460mg of yellow powder, which is organic and inorganic impurities. halide perovskite quantum dot material with CH in the core 3 NH 3 PbBr 3 . Calculate by calculating the yield formula 1., obtain final yield and be 65%;

[0067] Yield rate = total output mass / total input mass × 100% formula ①.

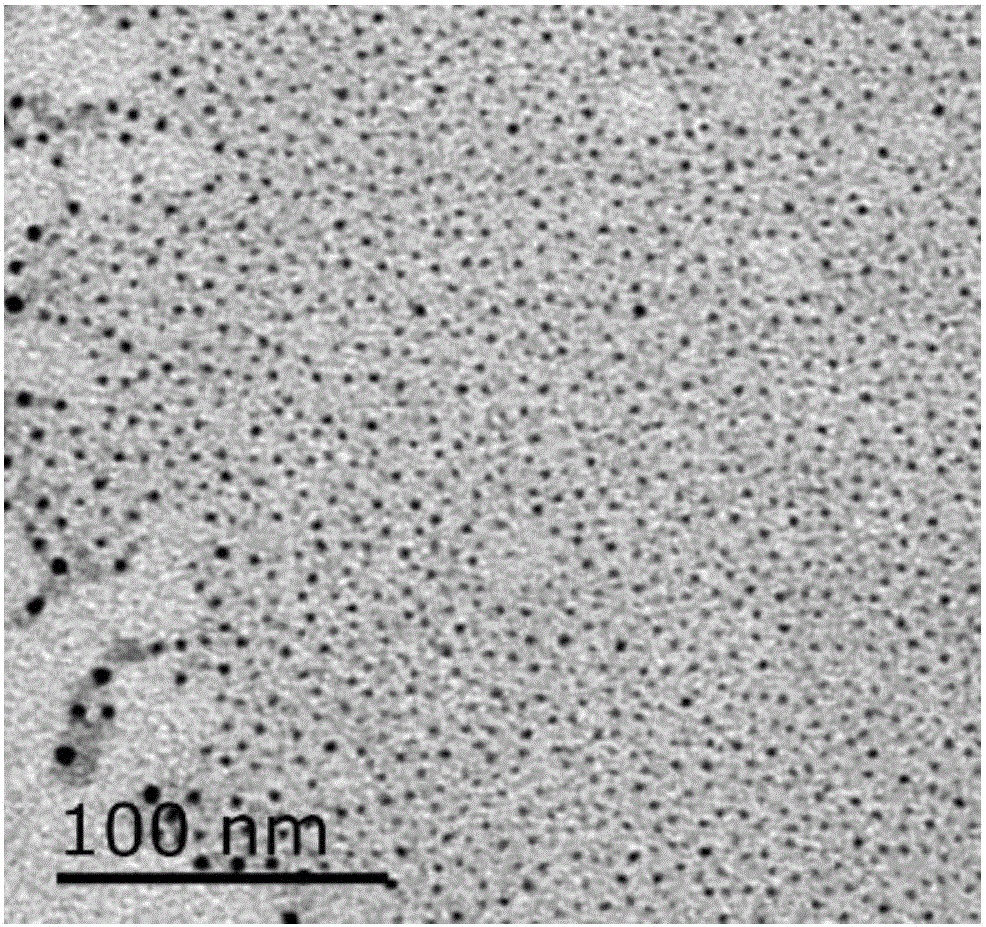

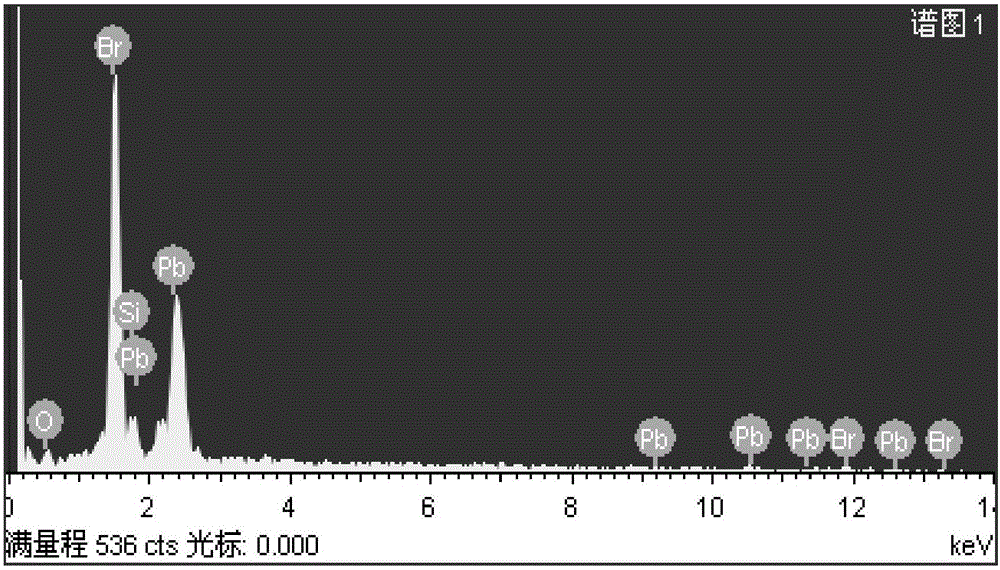

[0068] The perovskite quantum dot solution sample obtained in embodiment 1 is carried out transmission electron microscope (TEM) analysis, the result sees figure 1 , figure 1 It is the TEM result of the quantum dot material obtaine...

Embodiment 2

[0075] 1mmol PbBr 2 , 0.8 mmol CH 3 NH 3 Br and 2.0mmol APTS were miscible in DMF, and the resulting mixed solution was injected into rapidly stirring toluene to produce precipitation, and a solution sample of organic-inorganic hybrid perovskite quantum dots was obtained.

[0076] According to the same method in Example 1, centrifuge successively, dry, obtain yellow-green solid after drying, as Figure 4 The first sample on the left in the center was ground to obtain 412.6 mg of organic-inorganic hybrid perovskite quantum dot material in the form of solid powder.

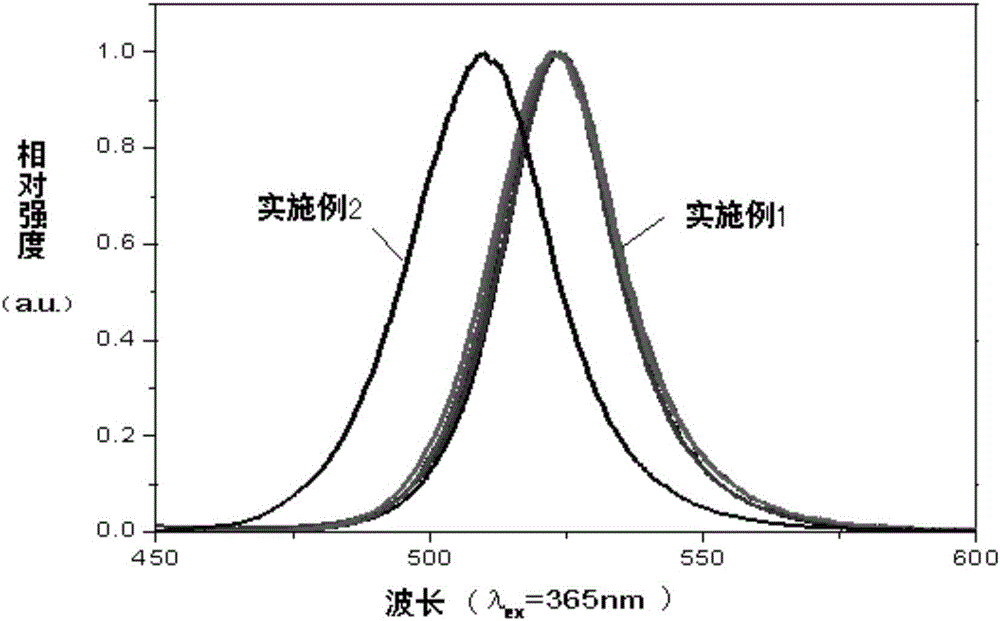

[0077] The emission spectrum of the solution sample is as image 3 shown, from image 3 The middle left curve can be obtained, the emission wavelength is 510nm, and the emission peak is narrow.

[0078] The situation of gained solid state material under the ultraviolet lamp sees Figure 5 The sample on the left side of the middle; the solid powder fluorescence quantum yield of the obtained material is detected...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com