Nano diamond alkene containing novel aqueous varnish and preparation method thereof

A nanodiamondene and water-based technology, applied in the direction of coating, etc., can solve the problems of weather resistance, scratch resistance, poor image quality, poor aging resistance, poor dispersion uniformity of powder wall paint, and environmental pollution, and achieve UV resistance Strong ability, improved scratch resistance, and low VOC content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

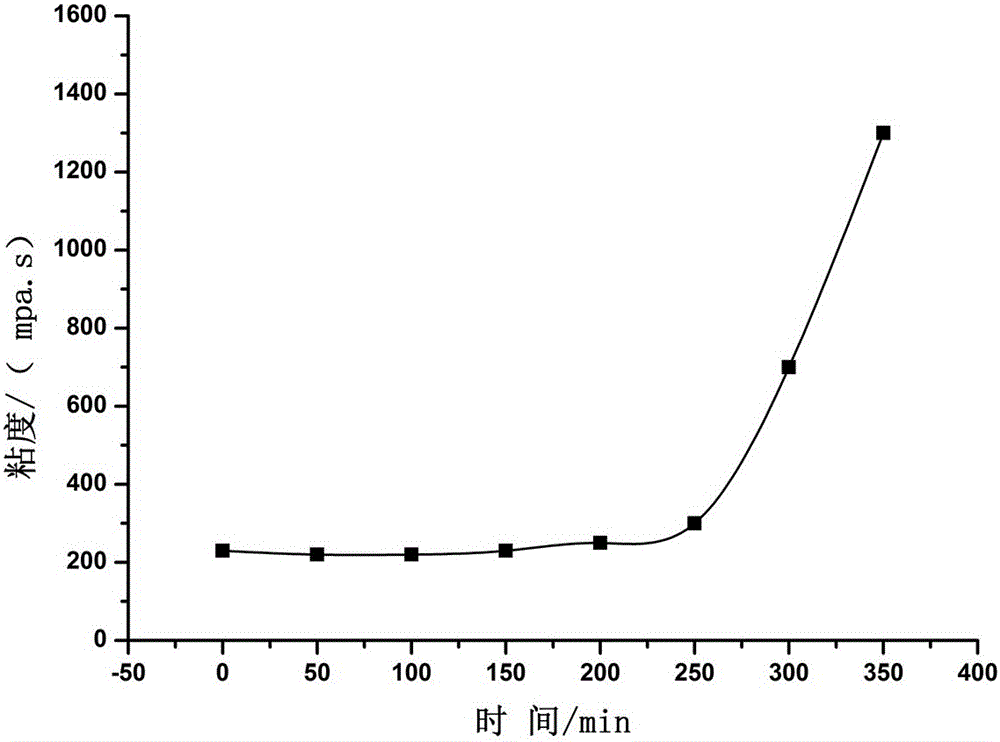

Image

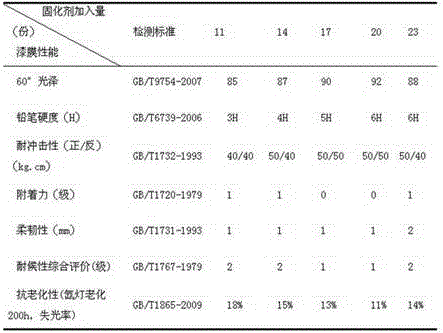

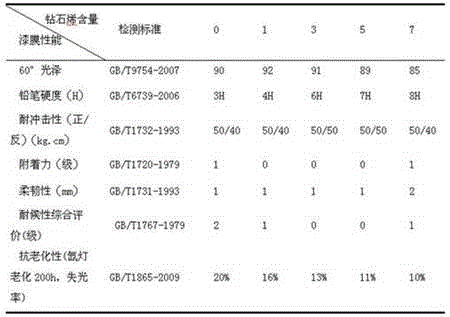

Examples

Embodiment 1

[0035] A novel water-based varnish containing nanodiamondene and a preparation method thereof, which are made of the following parts by weight:

[0036] The first component: 50 parts of hydroxy acrylate emulsion, 3.99 parts of nanodiamondene, 15 parts of deionized water, 0.6 parts of dispersant, 0.1 part of anti-settling agent, 0.01 part of defoaming agent, 0.2 part of leveling agent, film forming aid 4 parts of agent, 2 parts of thickener, 0.1 part of PH regulator;

[0037] The second component: 21 parts of curing agent, 3 parts of co-solvent;

[0038] The above-mentioned nanodiamondene is prepared by the following steps:

[0039] a. Ultrasonic alkaline cleaning: Put the nanodiamondene in the raw material into an ultrasonic cleaning machine equipped with lye, the ultrasonic frequency is 30KHz, the lye concentration is 8% NaOH solution, the lye temperature is controlled at 50 ℃, and the rotation is stirred , The stirring speed is 25rpm, and the cleaning is 25min;

[0040] b. Ultrasoni...

Embodiment 2

[0049] A novel water-based varnish containing nanodiamondene and a preparation method thereof, which are made of the following parts by weight:

[0050] The first component: 60 parts of hydroxy acrylate emulsion, 7 parts of nanodiamondene, 10 parts of deionized water, 0.39 parts of dispersant, 0.01 part of anti-settling agent, 0.1 part of defoaming agent, 1 part of leveling agent, film forming aid 3 parts of agent, 1.2 parts of thickener, 0.3 parts of PH regulator;

[0051] The second component curing agent: 15 parts, 2 parts co-solvent;

[0052] The above-mentioned nanodiamondene is prepared by the following steps:

[0053] a. Ultrasonic alkaline cleaning: Put the nanodiamondene in the raw material into an ultrasonic cleaning machine equipped with lye, the ultrasonic frequency is 30KHz, the lye concentration is 10% NaOH solution, the lye temperature is controlled at 55℃, and the rotating stirring , The stirring speed is 27rpm, and the cleaning is 27min;

[0054] b. Ultrasonic water w...

Embodiment 3

[0063] A novel water-based varnish containing nanodiamondene and a preparation method thereof, which are made of the following parts by weight:

[0064] The first component: 65.4 parts of hydroxy acrylate emulsion, 0.5 part of nanodiamondene, 5 parts of deionized water, 0.1 part of dispersant, 0.05 part of anti-settling agent, 0.05 part of defoaming agent, 0.4 part of leveling agent, film forming aid 2 parts, thickening agent 0.3, pH regulator 0.2;

[0065] The second component: 25 parts of curing agent, 1 part of co-solvent;

[0066] The above-mentioned nanodiamondene is prepared by the following steps:

[0067] a. Ultrasonic alkaline cleaning: Put the nanodiamondene in the raw material into an ultrasonic cleaning machine equipped with lye, the ultrasonic frequency is 30KHz, the lye concentration is 11% NaOH solution, the lye temperature is controlled at 57 ℃, and the rotating stirring , Stirring speed is 28rpm, cleaning 29min;

[0068] b. Ultrasonic water washing: Put the alkali-was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com