Preparation method for cable insulating material capable of realizing self-repairing of early-stage electrical-tree defects

A cable insulation and self-repair technology, which is applied in the production of bulk chemicals, etc., can solve the problems of high resource consumption, not widely used, and poor effect, and achieve high repair efficiency, increased repair ability, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

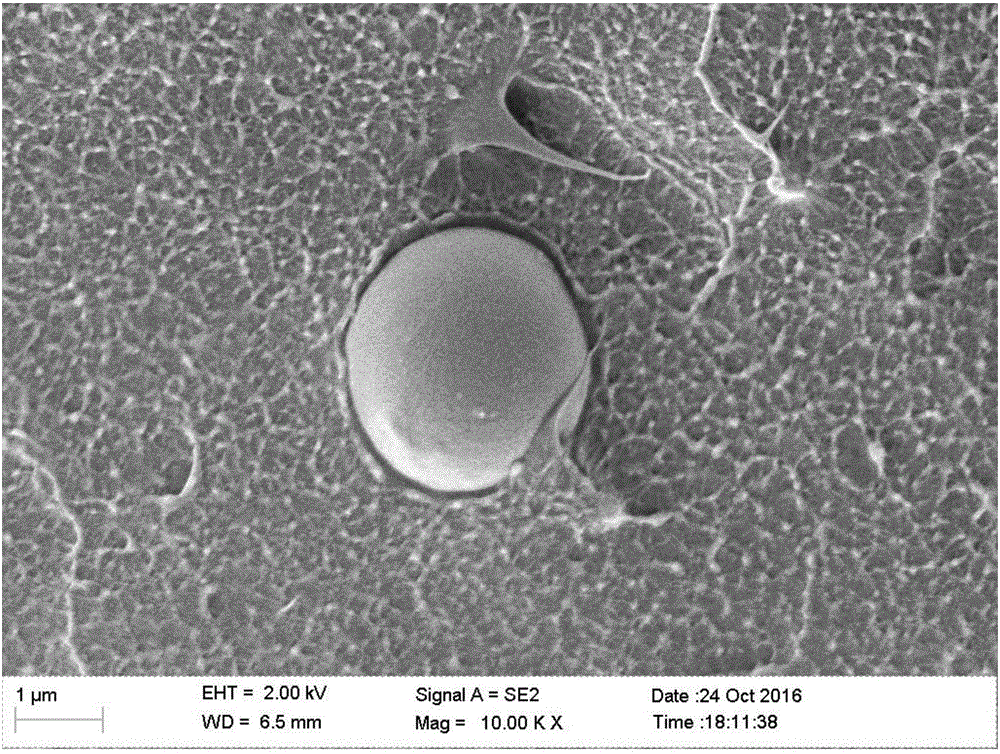

[0027] Such as figure 1 Shown is the preparation process of cable insulation materials for self-repairing early electric tree defects, specifically:

[0028] 1) Weigh 5 g of urea, mix 10 g of formaldehyde solution with a mass fraction of 37% in a container, and mechanically stir at a speed of 400 r / min until the urea is completely dissolved, adjust the pH to 8 with triethanolamine, and store at 70° C. After reacting for 1 hour, 40 g of distilled water was added to form a stable and transparent urea-formaldehyde prepolymer for use.

[0029] 2) Weigh 1 g of emulsifier sodium dodecylbenzene sulfonate and mix it with 10 g of molten dicyclopentadiene, stir it mechanically for 20 minutes at 50°C to fully emulsify it, and add 40 g of it dropwise During the emulsification process, an appropriate amount of defoamer n-octanol was added dropwise to eliminate the foam to obtain a core material emulsion.

[0030] 3) Add the solution obtained in step 1) dropwise to the solution obtained i...

Embodiment 2

[0033] 1) Weigh 5 g of urea, mix 10 g of formaldehyde solution with a mass fraction of 37% in a container, and mechanically stir at a speed of 400 r / min until the urea is completely dissolved, adjust the pH to 9 with triethanolamine, and store at 70° C. After reacting for 1 hour, 45 g of distilled water was added to form a stable and transparent urea-formaldehyde prepolymer for use.

[0034] 2) Weigh 1 g of emulsifier sodium dodecylbenzene sulfonate and mix it with 10 g of molten dicyclopentadiene, stir mechanically for 20 minutes at 50°C to fully emulsify, and add 34 g of emulsifier dropwise During the emulsification process, an appropriate amount of defoamer n-octanol was added dropwise to eliminate the foam to obtain a core material emulsion.

[0035] 3) Add the solution obtained in step 1) dropwise to the solution obtained in step 2) with mechanical stirring at a speed of 450r / min, and adjust the pH to about 3.5 with hydrochloric acid. After the microcapsules are formed, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com