Inner-drive multi-head installing device for powder shaft sleeve

A technology for installing devices and powders, which can be used in hand-held tools and manufacturing tools, etc. It can solve problems such as inconvenient hand pressing operations, unstable holding and releasing of tweezers, and shaking when pressing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

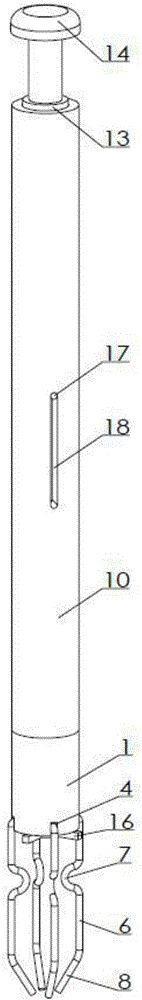

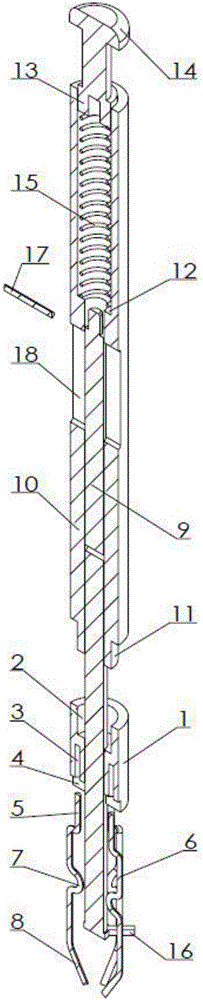

[0012] Examples of the present invention figure 1 , 2 As shown, the internal drive multi-head powder sleeve installation device is provided with a pick-up part and a handle part. The pick-up part is provided with a disassembly head 1 and an elastic wire. The disassembly head is a hollow tube. The upper end of the hollow tube is provided with a threaded interface 2. There are three or four vertical holes 3 equidistantly distributed in the upper direction of the lower end surface. There is a gap 4 between the vertical holes and the outer edge of the hollow tube. The elastic wires correspond to the vertical holes in the same number. It is made of plastic, as long as it is elastic and durable, the upper section 5 of the elastic thread is fixed in the corresponding vertical hole, and the elastic thread is bent into the notch at the notch to prevent rotation, and then bent downward to form a downwardly extending middle section 6 The middle part of the middle part of the elastic wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com