Method for preparing steel-aluminum dissimilar metal overlap joint by adopting CMT technology

A technology of dissimilar metals and overlapping joints, which is applied in the field of arc welding metals, can solve the problems of joint size and shape limitations, influence on joint mechanical properties, large heat input, etc., and achieve the effect of reducing heat input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

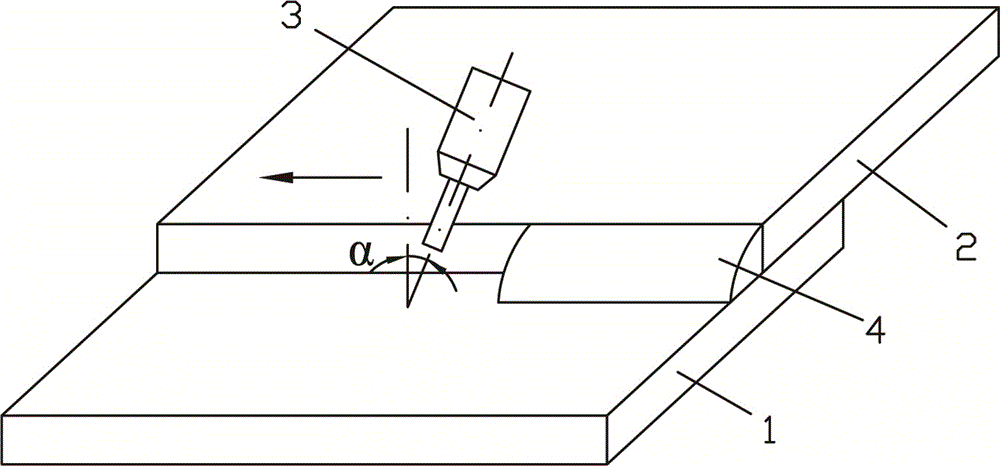

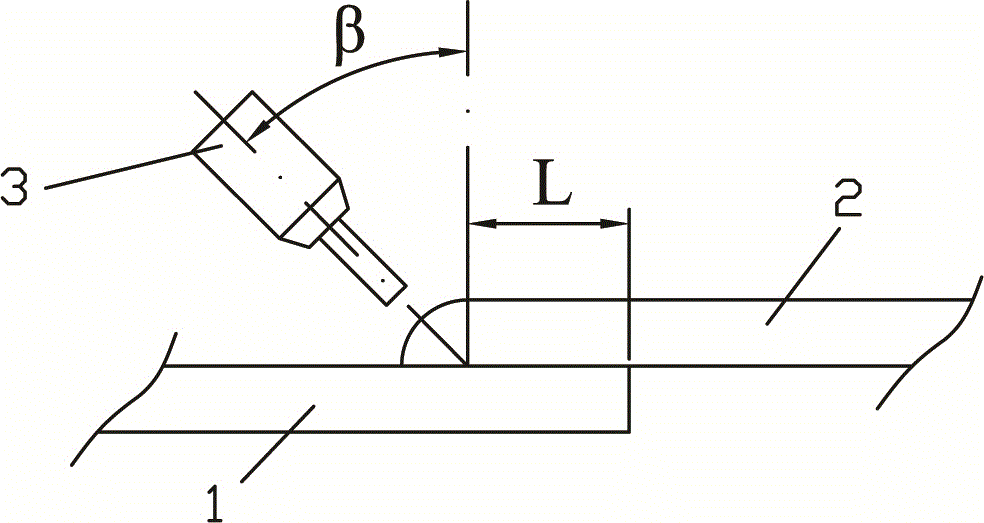

[0031] see figure 1 , figure 2 , the present invention adopts the CMT technology to prepare the method for lap joint of steel-aluminum dissimilar metals, in the welding process, the galvanized steel plate 1 is fixed on the workbench, and the aluminum alloy plate 2 is placed on the galvanized steel plate 1 in an overlapping manner, lapped The amount of contact L is between 5 and 20 mm, and fixed with a fixture; using a CMT welding machine, the welding torch 3 is inclined to the side of the aluminum alloy plate 2, and the vertical direction is β = 1° ~ 45°, and the welding torch is inclined to the forward direction α = 5 °~30°; the vertical distance between the welding torch 3 and the galvanized steel plate 1 is 10~20mm, and the welding speed is 0.4~1.0m / min.

[0032] Set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com