Treatment process and system for organic silica mud

A technology of treatment system and treatment process, which is applied in the field of organic silicon pulp and slag treatment, can solve the problems of inability to truly achieve harmless treatment, limit the development of the organic silicon industry, and easily generate other pollution sources, so as to achieve high production efficiency and environmental benefits Significant, high economic value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

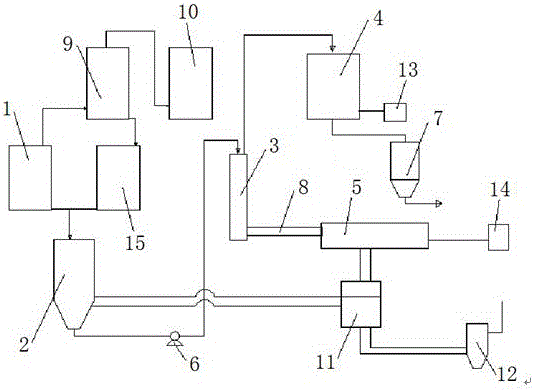

[0054] (1) Hydrolysis of disilane: Add 1 ton of organic silicon slurry and 2 tons of water into the hydrolysis tank 1 for reaction, and the reaction time is 60 minutes.

[0055] (2) Copper chloride leaching: keep the liquid level of the hydrolysis tank stable at about 80%, discharge the slurry of the hydrolysis tank to the stirring reactor, add an appropriate amount of hydrochloric acid, adjust the pH value of the solution to 0.5, the solution temperature is 40°C, and the stirring speed is 100rpm , start stirring and continue to react for 4 hours, take samples to detect the dissolution rate of copper in the slag, and stop the reaction when the leaching rate of copper reaches 99%.

[0056] (3) Pressing and backwashing: pump the slurry after leaching and reaction into the backwashing plate and frame filter press 3, the pressing pressure is 6Mpa, and backwashing with clean water after pressing, when the copper ion contained in the washing water is less than 0.05g / l after testing ...

Embodiment 2

[0060] The parameters of this embodiment are basically the same as those of Embodiment 1, the difference being that 1 ton of organic silicon slurry and 1.5 tons of water were added to the hydrolysis tank 1 for reaction, and the reaction time was 30 minutes.

[0061] In the copper chloride leaching step, the pH value of the solution is 1.5, the solution temperature is 70° C., the stirring speed is 80 rpm, and the stirring reaction time is 8 hours. The final output of sponge copper is 42.21 kg.

Embodiment 3

[0063] The parameters of this embodiment are basically the same as those of Embodiment 1, the difference being that 1 ton of organic silicon slurry and 1 ton of water are added to the hydrolysis tank 1 for reaction, and the reaction time is 10 minutes.

[0064] In the copper chloride leaching step, the leaching rate of copper is 99.5%, the pH value of the solution is controlled at 2, the temperature of the reaction solution is 90° C., the stirring speed is 100 rpm, and the reaction time is 1 hour. In the end, 1 ton of organic silicon slurry slag yields 42.64 kg of sponge copper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com