PTFE hollow fiber film used for bubbleless aeration oxygenation, and preparation method thereof

A non-foam aeration, PTFE technology, applied in water aeration, chemical instruments and methods, membrane technology, etc., can solve the problems of single use, low porosity, high cost, easy operation, high porosity, resistance small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

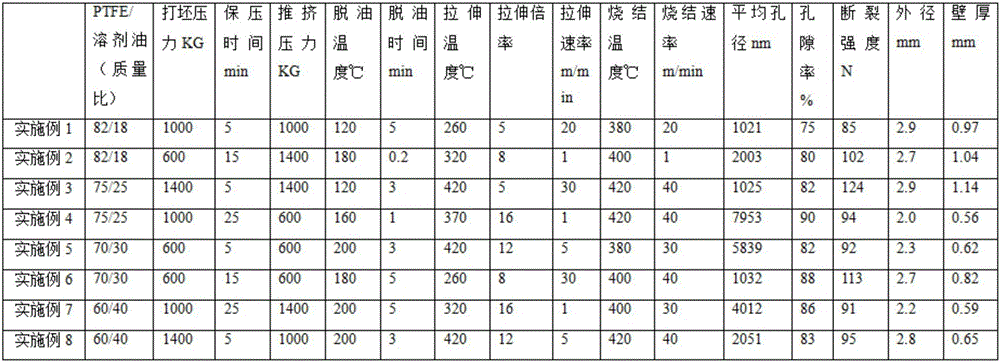

Embodiment 1

[0024] A preparation method for bubble-free aeration and oxygenation PTFE hollow fiber membrane, comprising the steps of:

[0025] 1) Take polytetrafluoroethylene powder (Chenguang 216G) with a mass ratio of 82% and 18% paraffin oil in a "V"-shaped mixer and mix evenly, then age at 45°C for 18 hours;

[0026] 2) Put the mixture into a blanking machine, punch it under a pressure of 1000KG, take it out after holding the pressure for 5 minutes, put it into a pusher, and push it under a pressure of 1000KG to form a nascent PTFE hollow fiber membrane;

[0027] 3) Deoiling the obtained nascent PTFE hollow fiber membrane in a deoiler at 120° C. for 5 minutes in sequence;

[0028] 4) After deoiling, the PTFE hollow fiber membrane is stretched 5 times in the axial direction at 260°C in the stretching machine, and the stretching rate is 20m / min;

[0029] 5) After the stretching is completed, enter the sintering furnace at 380°C for sintering at a vehicle speed of 20m / min, and prepare a...

Embodiment 2

[0031] A preparation method for bubble-free aeration and oxygenation PTFE hollow fiber membrane, comprising the steps of:

[0032] 1) Take polytetrafluoroethylene powder (Chenguang 216G) with a mass ratio of 75%, and 25% white oil, put them in a "V"-shaped mixer, mix them evenly, and age them at 45°C for 18 hours;

[0033] 2) Put the mixture into a blanking machine, punch it under a pressure of 1000KG, take it out after holding the pressure for 15 minutes, put it into a pusher, and push it under a pressure of 1400KG to form a nascent PTFE hollow fiber membrane;

[0034] 3) The nascent PTFE hollow fiber membranes are deoiled at 180°C for 0.2min in the deoiler in turn;

[0035] 4) After deoiling, the PTFE hollow fiber membrane is stretched 8 times in the axial direction at 320°C in a stretching machine, and the stretching rate is 1m / min;

[0036] 5) After the stretching is completed, enter the sintering furnace at 400°C for sintering at a vehicle speed of 1m / min, and prepare a ...

Embodiment 3

[0038] A preparation method for bubble-free aeration and oxygenation PTFE hollow fiber membrane, comprising the steps of:

[0039] 1) Take polytetrafluoroethylene powder (Daikin F104) with a mass ratio of 75% and 25% kerosene in a "V"-shaped mixer and mix evenly, then age at 45°C for 18 hours;

[0040] 2) Put the mixture into the blanking machine, punch it under a pressure of 1400KG, take it out after keeping the pressure for 5 minutes, put it into a pushing machine, and push it under a pressure of 1400KG to form a nascent PTFE hollow fiber membrane;

[0041] 3) The nascent PTFE hollow fiber membranes are deoiled in a deoiler at 120°C for 3 minutes in sequence;

[0042] 4) After deoiling, the PTFE hollow fiber membrane is stretched 5 times in the axial direction at 420°C in the stretching machine, and the stretching rate is 30m / min;

[0043] 5) After the stretching is completed, enter the sintering furnace at 420°C for sintering at a speed of 40m / min, and prepare a PTFE hollo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com