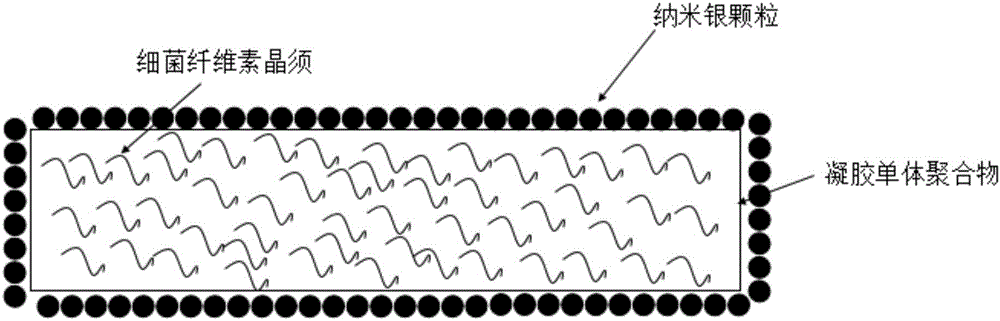

Transparent antibacterial hydrogel dressing as well as preparation method and application thereof

A hydrogel and transparent technology, which is applied in the field of polymer materials and biomaterials, can solve the problems of low water content and poor antibacterial effect, and achieve the effect of improved antibacterial performance, good mechanical strength and flexibility, and short time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The preparation method of described hydrogel dressing, comprises the steps:

[0053] (1) Inoculate bacterial cellulose-producing bacteria in a liquid medium, culture statically at 25°C to 30°C for at least one week to obtain a cellulose film, soak the obtained cellulose film in distilled water for 2 to 4 days, and then place it Into a concentration of 0.1mol / LNaOH solution and boil for 30 minutes, the purpose is to remove the remaining thalline and culture medium, then rinse with deionized water until neutral to obtain bacterial cellulose film;

[0054] (2) The bacterial cellulose film obtained in step (1) is smashed, and the upper layer is taken by centrifugation to obtain the centrifuged cellulose, and the centrifuged cellulose is added to a volume concentration of 40% to 60% sulfuric acid, at 40°C Under the condition of ~60°C, carry out the hydrolysis reaction for 8 hours to 12 hours, after the hydrolysis is completed, perform centrifugation, dialysis, and centrifuga...

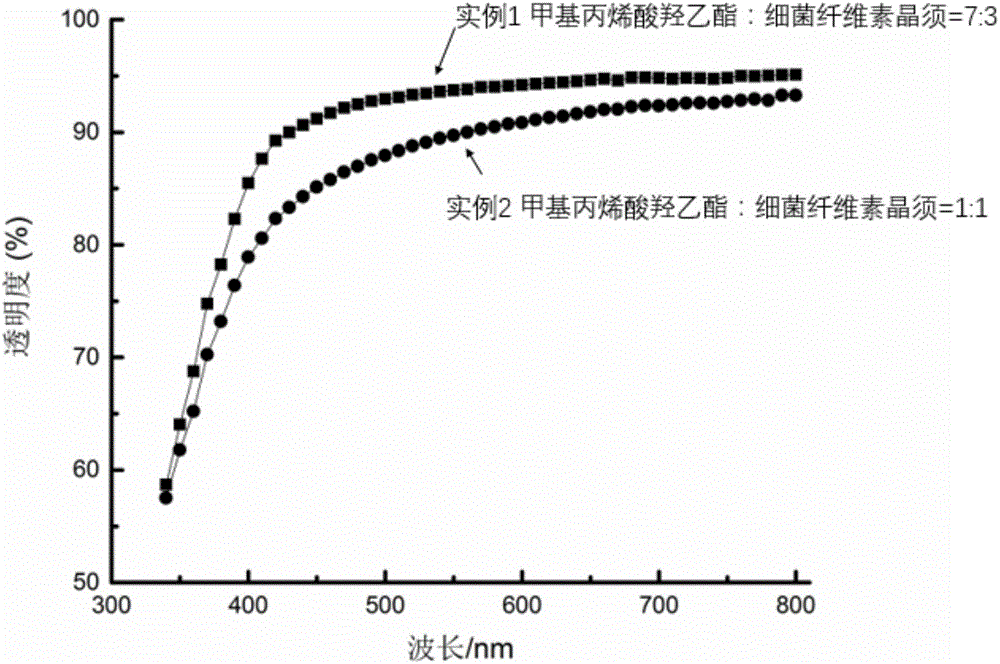

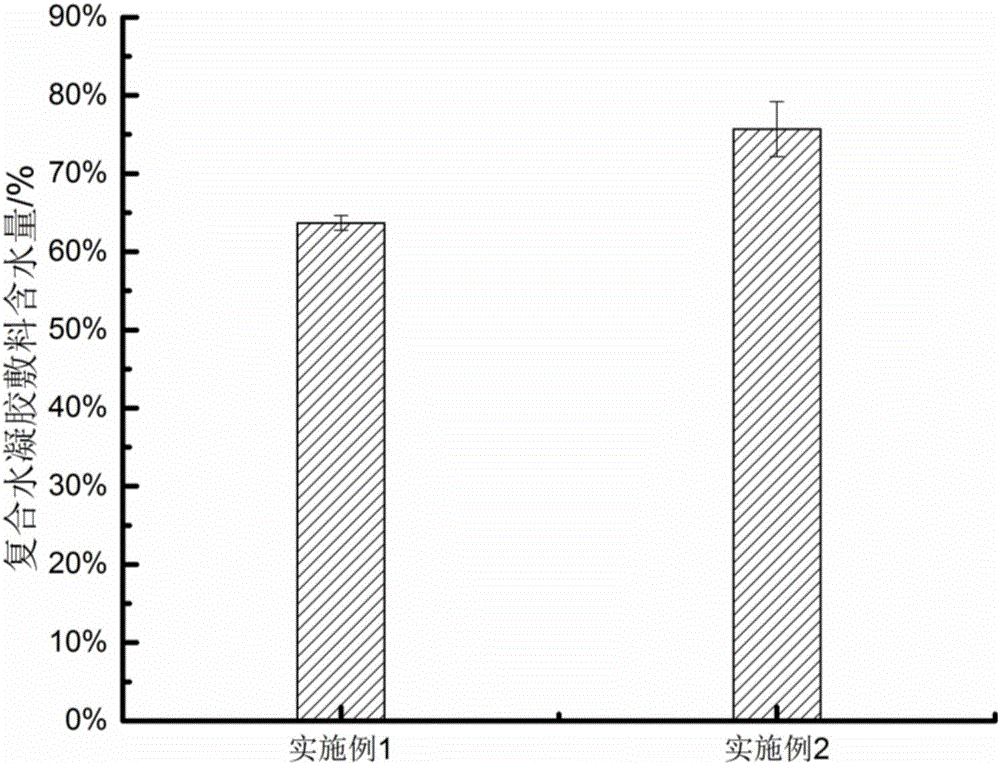

Embodiment 1

[0072] (1) The bacterium used in the experiment was Gluconacetobacter, which was inoculated in HS medium and cultured statically in a biochemical incubator at 30°C for one week to obtain a bacterial cellulose film with a thickness of about 10 mm. Boil with 0.1mol / L NaOH solution for half an hour to remove bacterial residues in the culture medium, then soak in deionized water for a week until the pH is neutral, and the purified cellulose membrane can be obtained.

[0073] (2) Mash the bacterial fiber membrane into a slurry, centrifuge (10000 rpm, 10 minutes) to remove the moisture in the homogenate, take the upper layer, and obtain the cellulose after centrifugation; configure 200ml 50% concentrated sulfuric acid, weigh and centrifuge The cellulose, according to adding 200ml 50% concentrated sulfuric acid in every 100g cellulose, water bath 60 ℃ for about 8 hours. After the hydrolysis is completed, first perform centrifugation treatment (10000 rpm, 10 minutes), take the upper l...

Embodiment 2

[0077] Repeat embodiment 1 with described same step, difference is, in step (3), hydroxyethyl methacrylate and bacterial cellulose whisker volume ratio are 1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com