By-product industrial salt melting furnace having effect of reducing precipitation of metal ions

A technology for metal ions and industrial salts, applied in the field of by-product industrial salt melting furnaces, can solve problems such as affecting the normal carbonization of inorganic salts, precipitation of metal ions, shortening service life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

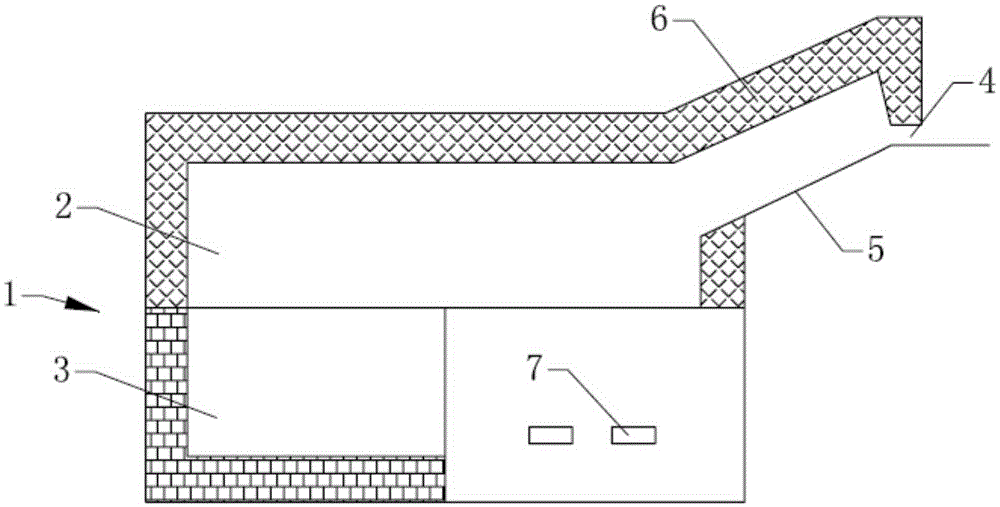

[0053] Such as figure 1 Shown, a kind of by-product industrial salt melting furnace that reduces the precipitation of metal ions includes a furnace chamber body 1 surrounded by a plurality of furnace wall surfaces. The furnace chamber body 1 has an upper part defined as a heating chamber 2 and defined as a melting chamber. The lower part of the cavity 3, the furnace cavity body 1 is provided with a feeding port 4, and the downstream of the feeding port 4 is provided with an inclined feeding channel 5 for guiding the solid by-product industrial salt to the inside of the melting chamber 3, so The furnace cavity body is provided with a dome 6 having the same inclination angle as that of the feed channel 5 above the feed channel 5, and a plurality of slag outlets 7 are provided on the lower side wall of the melting chamber 3. The slag discharge port 7 is an elongated opening, and the aspect ratio of the slag discharge port 7 is 3:1.

[0054] The refractory bricks of the heating c...

Embodiment 2

[0075] The structure of this embodiment is the same as that of Embodiment 1, the difference is that:

[0076] The refractory bricks of the heating chamber described in this embodiment are prepared with the following components by weight:

[0077] Mullite powder 25 parts,

[0078] 35 parts of silicon carbide powder,

[0079] 15 parts of silicon dioxide powder,

[0080] 25 parts of alumina micropowder,

[0081] Forsterite powder 15 parts,

[0082] Vermiculite powder 10 parts

[0083] Quartz powder 25 parts,

[0084] Zircon powder 20 parts,

[0085] 15 parts of sillimanite powder;

[0086] The refractory bricks of the melting chamber are prepared using the following components in parts by weight:

[0087] 35 parts of silicon nitride fine powder,

[0088] 25 parts of silicon carbide micropowder,

[0089] 20 parts of silicon dioxide powder,

[0090] Boron carbide powder 15 parts,

[0091] 25 parts of silica sol.

[0092] The refined industrial salt index prepared by th...

Embodiment 3

[0096] The structure of this embodiment is the same as that of Embodiment 1, the difference is that:

[0097] The refractory bricks of the heating chamber described in this embodiment are prepared using the following components by weight: 25 parts of mullite powder,

[0098] 30 parts of silicon carbide powder,

[0099] 15 parts of silicon dioxide powder,

[0100] 20 parts of alumina micropowder,

[0101] Forsterite powder 13 parts,

[0102] Vermiculite powder 8 parts

[0103] Quartz powder 25 parts,

[0104] Zircon powder 15 parts,

[0105] 10 parts of sillimanite powder.

[0106] The refractory bricks of the melting chamber are prepared using the following components in parts by weight:

[0107] 30 parts of silicon nitride micropowder,

[0108] 25 parts of silicon carbide micropowder,

[0109] 15 parts of silicon dioxide powder,

[0110] Boron carbide powder 10 parts,

[0111] 20 parts of silica sol.

[0112] The refined industrial salt index prepared by the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com