Catalyst for preparation of acetaldehyde through hydrogenation, and preparation method and application thereof

A technology for catalysts and acetaldehyde, applied in hydrogenolysis preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of low catalyst acetaldehyde selectivity, high catalyst cost, and high cost , to achieve reliable repeatability, good thermal stability, and increase the effect of contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

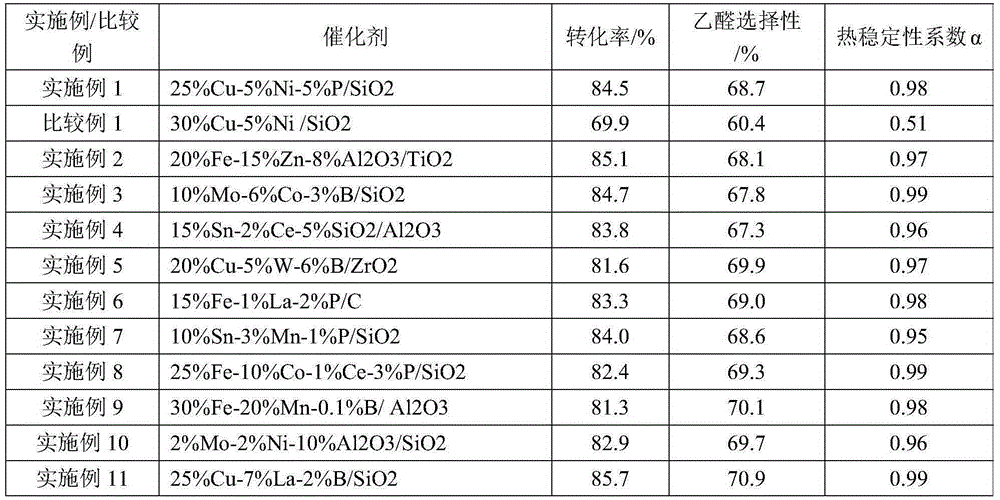

Examples

Embodiment 1

[0031] 25%Cu-5%Ni-5%P / SiO2 catalyst:

[0032] Dry the silica carrier at 110°C for 10 h, then weigh 20 g of the dried silica carrier, add it to 100 g of ethylene glycol monomethyl ether (EM), stir ultrasonically for 0.5 h, and then add 10 g of Hexamethyldisilazane (HMDS), the mixture was refluxed under nitrogen for 10h, then the mixture was washed with ethylene glycol monomethyl ether, and dried at 110°C for 24h to obtain a modified silica carrier . Dissolve 9.50g of copper nitrate in 20ml of deionized water, add 10g of modified silica carrier, stir ultrasonically for 2h, then stir and evaporate to dryness at 90°C, and then dry at 70°C for 8h, and the obtained solid is in Roast at 300°C for 6h to obtain solid A; prepare 0.1g / mL phosphoric acid aqueous solution, take 15.8mL, add solid A quickly, stir ultrasonically for 2h, then stir and evaporate to dryness at 80°C, and then dry at 100°C 6h, the obtained solid was roasted at 400°C for 5h to obtain solid B; 2.48g of nickel nitr...

Embodiment 2

[0043] 20%Fe-15%Zn-8%Al2O3 / TiO2 catalyst:

[0044] Titanium dioxide was dried at 80° C. for 24 h, then 15 g of dried titanium dioxide was weighed, added to 300 g of ethylene glycol monomethyl ether (EM), ultrasonically stirred for 1 h, and then 3 g of hexamethyldisilazane ( HMDS), the mixture was refluxed under argon for 4 h, then the mixture was washed with ethylene glycol monomethyl ether, and dried at 120° C. for 10 h to obtain modified titanium dioxide. Dissolve 14.43g of ferric nitrate in 30ml of deionized water, add 10g of modified titanium dioxide, stir ultrasonically for 0.5h, stir and evaporate to dryness at 70°C, and then dry at 50°C for 12h. Roast at ℃ for 8h to obtain solid A; prepare 0.2g / mL aluminum nitrate aqueous solution, take 16.7mL, add solid A quickly, stir ultrasonically for 1h, then stir and evaporate to dryness at 90℃, and then dry at 110℃ 4h, the obtained solid was roasted at 400°C for 6h to obtain solid B; 6.83g of zinc nitrate was dissolved in 20ml o...

Embodiment 3

[0049] 10%Mo-6%Co-3%B / SiO2 catalyst:

[0050] Dry the silica carrier at 100°C for 20 h, then weigh 15 g of the dried silica, add it to 100 g of ethylene glycol monomethyl ether (EM), stir ultrasonically for 1 h, and then add 6 g of hexamethyldisilazol Azane (HMDS), the mixture was refluxed under nitrogen for 4 h, then the mixture was washed with ethylene glycol monomethyl ether, and dried at 100° C. for 30 h to obtain a modified silica carrier. Dissolve 1.84g of ammonium molybdate in 15ml of deionized water, add 10g of modified silica, stir ultrasonically for 2 hours, evaporate to dryness with stirring at 80°C, then dry at 110°C for 4 hours, and dry the obtained solid at 450°C Roast at low temperature for 2 hours to obtain solid A; prepare 0.1g / mL boric acid aqueous solution, take 17.2mL, add solid A quickly, after ultrasonic stirring for 1 hour, stir and evaporate to dryness at 70°C, and then dry at 100°C for 6 hours, the obtained The solid was roasted at 350°C for 6 hours t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com