A kind of phosphite powder body coated with nano-oxide inorganic coating and water-based coating containing the powder body

A nano-oxide and phosphite technology, used in inorganic pigment treatment, anti-corrosion coatings, coatings, etc., can solve problems such as undiscovered, achieve high production efficiency, improve anti-corrosion performance, and strengthen anti-rust effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

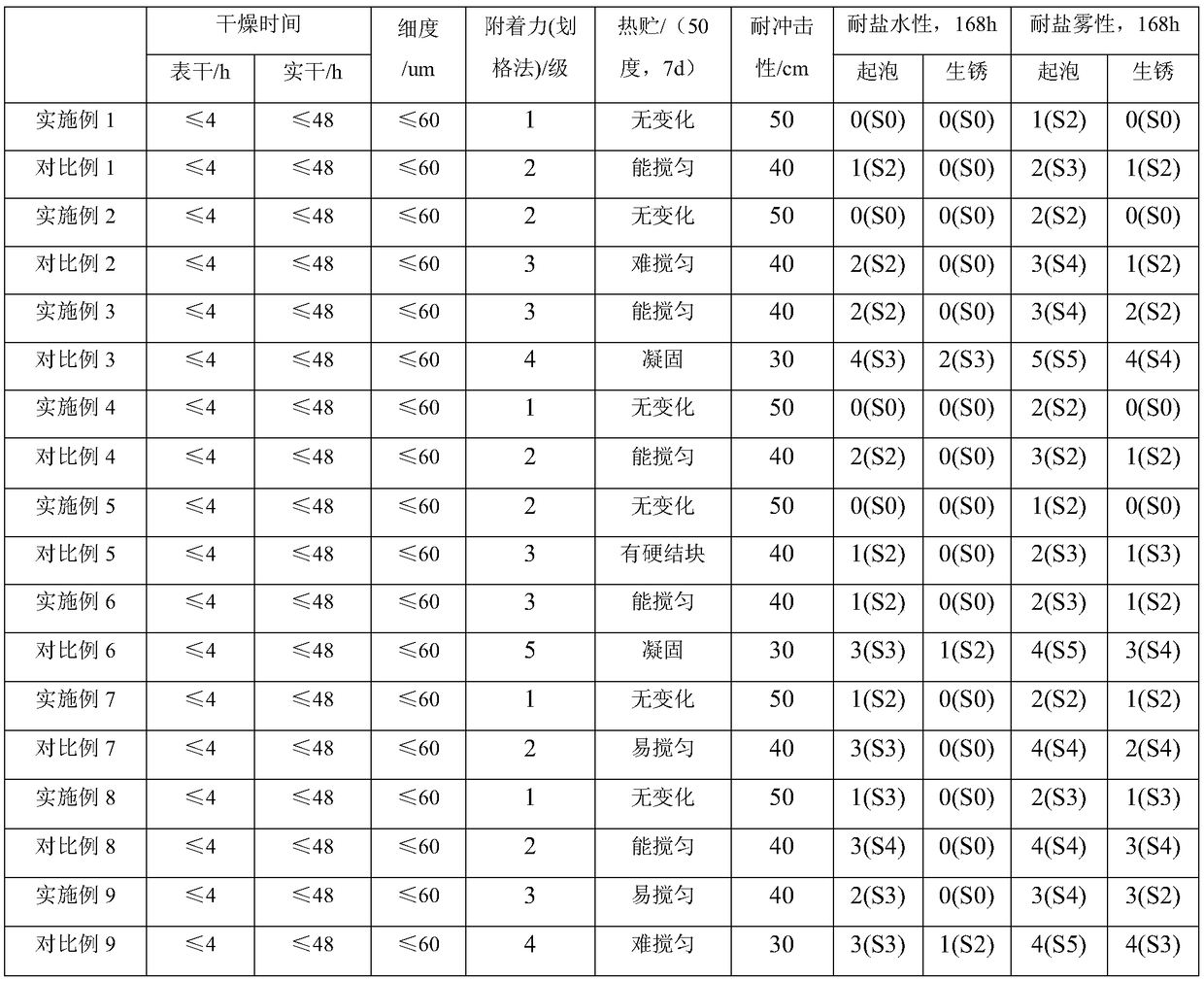

Examples

Embodiment 1

[0039] 1. Preparation of nano-oxide inorganic coated phosphite powder:

[0040] The mixture of iron phosphite and zinc phosphite is used as the core, and the mixture of nano-MgO and CaO is used as the shell. The mixture of nano-MgO and CaO covers the mixture of iron phosphite and zinc phosphite. The mass is 0.1% of the mass of the mixture of iron phosphite and zinc phosphite.

[0041] The preparation method of this phosphite powder comprises the following steps:

[0042] The mixture of 5kg iron phosphite and 5kg zinc phosphite is crushed, sieved, and the phosphite mixture with a particle size of 0.2 μm is collected, and 0.01kg sodium metaphosphate and 0.01kg sodium phosphate are added as a dispersant to mix and disperse. After adding sodium hydroxide and mixing to adjust the pH to 8, as the basic carrier, the mixture of MgO 0.005kg and CaO 0.005kg with a particle size of 20nm is used for coating reaction in a rod mill. The temperature of the coating reaction is 20°C, and the ...

Embodiment 2

[0050] 1. Preparation of nano-oxide inorganic coated phosphite powder:

[0051] With the mixture of calcium phosphite, strontium phosphite and magnesium phosphite as the core, nano-Al 2 o 3 , SiO 2 , ZrO mixture as the shell, nano-Al 2 o 3 , SiO 2 The mixture of , ZrO wraps the mixture of calcium phosphite, strontium phosphite and magnesium phosphite, among which, the nanometer Al 2 o 3 , SiO 2 The mass of the mixture of ZrO and ZrO is 1% of the mass of the mixture of calcium phosphite, strontium phosphite and magnesium phosphite.

[0052] The preparation method of this phosphite powder comprises the following steps:

[0053] Grind the mixture of 3kg calcium phosphite, 3kg strontium phosphite and 4kg magnesium phosphite, sieve, collect the phosphite mixture with a particle size of 0.5μm, add 0.1kg sodium polyphosphate and 0.1kg silicone dispersant as dispersion Mixing agent for dispersion treatment, while adding potassium hydroxide and mixing to adjust the pH to 9, as...

Embodiment 3

[0061] 1. Preparation of nano-oxide inorganic coated phosphite powder:

[0062] With the mixture of aluminum phosphite and copper phosphite as the core, nano SrO, Fe 2 o 3 、TiO 2 , CuO mixture as the shell, nano SrO, Fe 2 o 3 、TiO 2 A mixture of , CuO wraps the mixture of aluminum phosphite and copper phosphite, among which, nanometer SrO, Fe 2 o 3 、TiO 2 The mass of the mixture of aluminum phosphite and copper phosphite is 5% of the mass of the mixture of aluminum phosphite and copper phosphite.

[0063] The preparation method of this phosphite powder comprises the following steps:

[0064] The mixture of 4kg of aluminum phosphite and 6kg of copper phosphite is pulverized, sieved, and the phosphite mixture with a particle size of 2 μm is collected, and 0.3kg of sodium metaphosphate and 0.3kg of organosilicon dispersant are added as a dispersant and mixed for dispersion treatment. At the same time, after adding calcium hydroxide and mixing to adjust the pH to 12, as t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com