Method for synthesizing nano-sized zeolite molecular sieve suitable for VOCs adsorption

A synthesis method and nano-zeolite technology, applied in separation methods, nanotechnology, chemical instruments and methods, etc., can solve the problems of expensive template agent, long reaction time, unsuitable for industrial production, etc., and achieve good adsorption effect and crystallization. The effect of shortened time and super hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

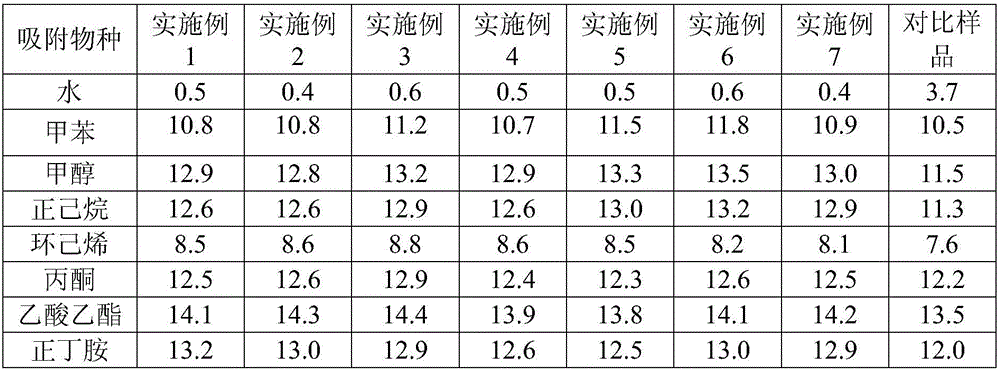

Examples

Embodiment 1

[0036] Embodiment 1, the synthesis that is applicable to the nanometer zeolite molecular sieve of VOCs adsorption

[0037] (1), weigh 29.89mol of deionized water, 0.5mol of methyltrimethoxysilane and 0.5mol of ethyltrimethoxysilane (organosilylating agent), stir well and then add 0.6g of nonionic surfactant P123 and 0.005mol sodium fluoride, mix evenly, heat to 80±5°C, keep stirring for 4±0.5h, open the door to remove the methanol generated by hydrolysis, and obtain the pretreatment solution;

[0038] (2), add 0.01mol gallium chloride, 6.5g 70% (mass) ethylamine aqueous solution (containing 0.11mol water, 0.1mol ethylamine) to the pretreatment liquid, put into the stainless steel reaction kettle after mixing evenly, airtight 150 ℃ After crystallization for 20 h, a milky white suspension was obtained.

[0039] (3) The suspension was suction filtered, washed with 200 g of deionized water, dried at 110° C. for 6 hours, and calcined at 500° C. for 3 hours to obtain a white powder p...

Embodiment 2

[0043] Embodiment 2, the synthesis that is suitable for the nano-zeolite molecular sieve of VOCs adsorption

[0044] In step (1), the amount of deionized water is 50mol, the organic silylating agent is 0.3mol methyltrimethoxysilane and 0.7mol dimethyldimethoxysilane, and the amount of nonionic surfactant P123 is 1.8g, The amount of sodium fluoride was 0.01 mol.

[0045] In step (2), the heteroatom salt is 0.01 mol of germanium nitrate, the organic amine is 0.05 mol of propylamine, the crystallization temperature is 160° C., and the crystallization time is 40 h, and a white powder product B is prepared.

[0046] Among them, organosilylating reagents (using SiO 2 The molar ratio of sodium fluoride, inorganic heteroatom salt, templating agent and water is 1:0.01:0.01:0.05:50, P123 and organosilylating reagent (using SiO 2 The mass ratio of meter) is 0.03:1.

[0047] Measured by X-ray powder diffraction method, the white powder product B is ZSM-5 molecular sieve, the relative c...

Embodiment 3

[0048] Embodiment 3, the synthesis that is suitable for the nano-zeolite molecular sieve of VOCs adsorption

[0049] In step (1), the deionized water is 9.74mol, the organosilylating agent is 1mol diethyldimethoxysilane, the amount of nonionic surfactant P123 is 1.2g, and the amount of sodium fluoride is 0.03mol;

[0050] In step (2), the heteroatom salt is 0.01mol titanium sulfate, and the organic amine is a mixture of 7.8g 40 (mass)% methylamine aqueous solution (containing 0.1mol methylamine, 0.26mol water) and 0.1mol n-butylamine, crystallized The temperature is 140° C., the crystallization time is 100 h, and a white powder product C is prepared.

[0051] Among them: organosilylating reagents (using SiO 2 The molar ratio of sodium fluoride, inorganic heteroatom salt, templating agent and water is 1:0.03:0.01:0.2:10, and the mass ratio of P123 to organosilylating reagent (based on SiO 2 Count) is 0.02:1.

[0052] As determined by the X-ray powder diffraction method, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com