High-frequency colored covering film

A cover film and high frequency technology, applied in the field of colored cover films, can solve the problems that colored cover films cannot meet the electrical requirements and are difficult to apply in the high frequency field, and achieve the effects of good electrical properties, simple methods and good adhesion.

Inactive Publication Date: 2017-04-26

KUSN APLUS TEC CORP

View PDF4 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This makes it difficult for the colored cover film to be applied in the high-frequency field because it cannot meet the electrical requirements at high frequencies.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

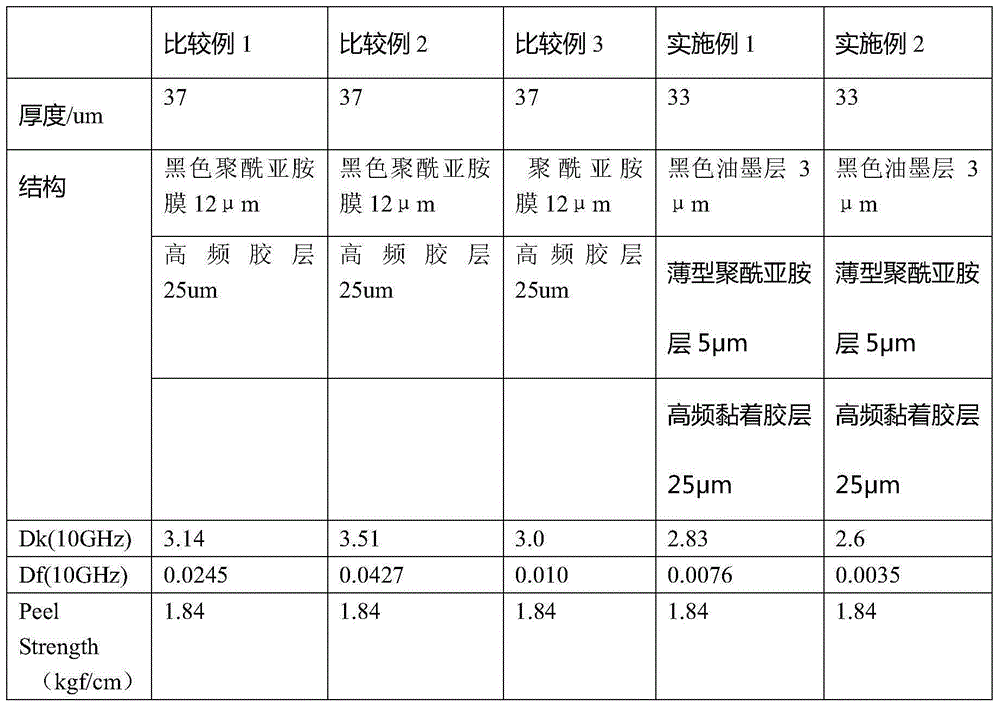

[0034] The difference between Example 1 and Example 2 lies in the addition ratio of the low-dielectric powder in the adhesive layer. In Example 1, the addition rate of the low dielectric powder in the adhesive layer is 20%; in Example 2, the addition rate of the low dielectric powder in the adhesive layer is 50%.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

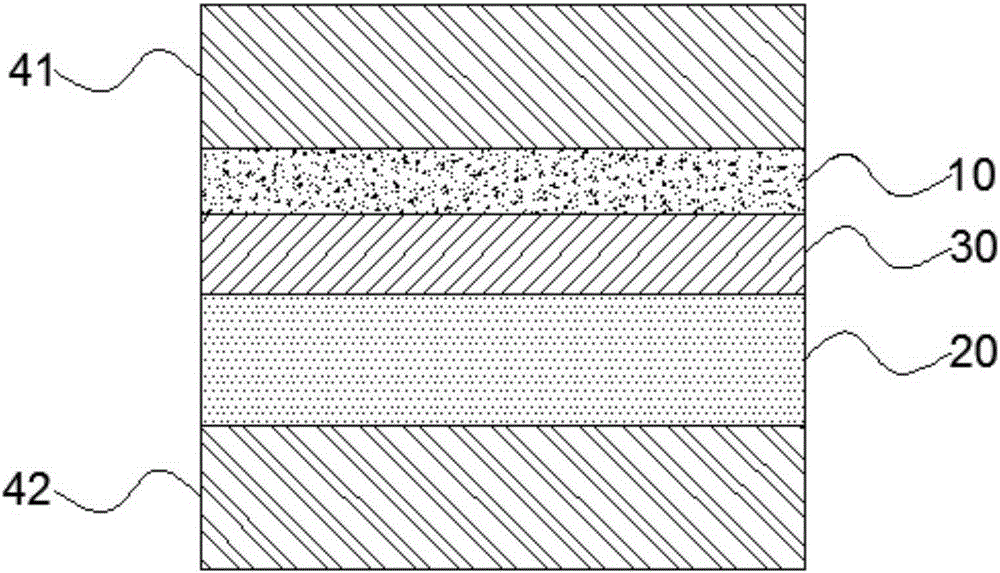

The present invention discloses a high-frequency colored covering film, which comprises an ink layer, an adhesive layer, a thin polyimide layer and a release layer, wherein the adhesive layer contains a polyimide resin-based resin, the thickness of the thin polyimide layer is 5-10 [mu]m, the thin polyimide layer is formed between the ink layer and the adhesive layer, and the release layer covers the outer surface of at least one of the ink layer and the adhesive layer. According to the present invention, the high-frequency colored covering film has good electric property under high frequency, can be prepared through the simple method, has advantages of good adhesion force and line shielding function, can reduce the dielectric loss of the electronic material in the cases of the rapid propagation and the increased signal loss in the modern 4G industry, and meets the industrial requirements of high speed and low loss.

Description

technical field [0001] The invention belongs to the technical field of cover films for printed circuit boards, in particular to a colored cover film with good electrical properties at high frequencies. Background technique [0002] At present, electronic systems are developing in the direction of thinness, lightness, high heat resistance, multi-functionality, high density, high reliability and low cost. In terms of functions, powerful and high-speed signal transmission is required. In the high-frequency field, wireless infrastructure needs to provide low enough insertion loss to effectively improve energy utilization. With the advent of 4G services, radio frequency products need to provide wider bandwidth and be backward compatible with 3G and 2G services. In the current high-frequency cover film, the material of the cover film is generally polyimide. Due to the addition of carbon powder to polyimide, the black cover film has a relatively large Dk / Df value, which is diffic...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B32B27/34B32B27/06B32B7/06

CPCB32B7/06B32B27/06B32B27/34B32B2307/4023B32B2457/08

Inventor 李韦志杜伯贤林志铭陈辉

Owner KUSN APLUS TEC CORP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com