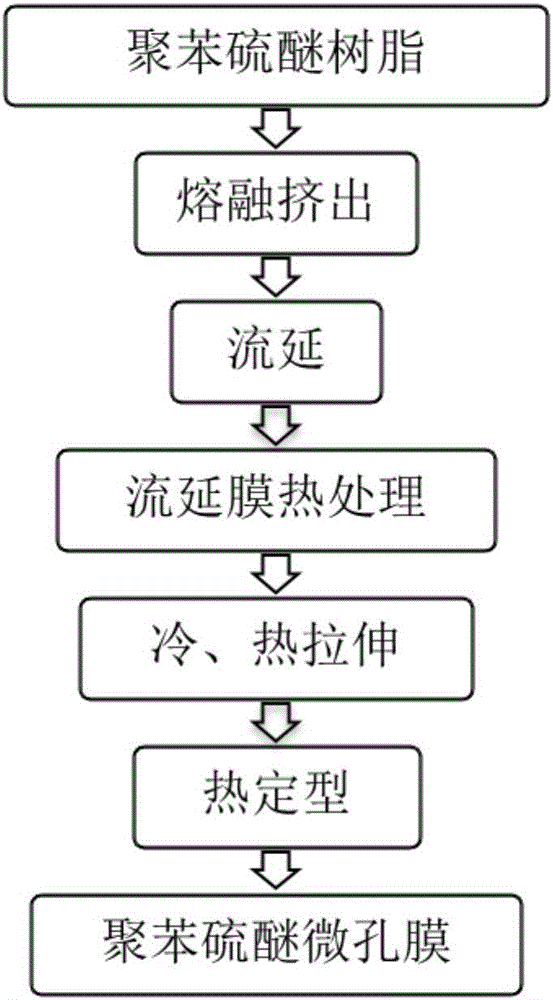

Polyphenylene sulfide microporous membrane containing lamella structure and preparation method thereof

A technology of polyphenylene sulfide and polyphenylene sulfide resin, which is applied to flat products, other household appliances, applications, etc., can solve the problems of poor continuity and stability, complicated production process and high production cost, and achieves good continuity, Simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

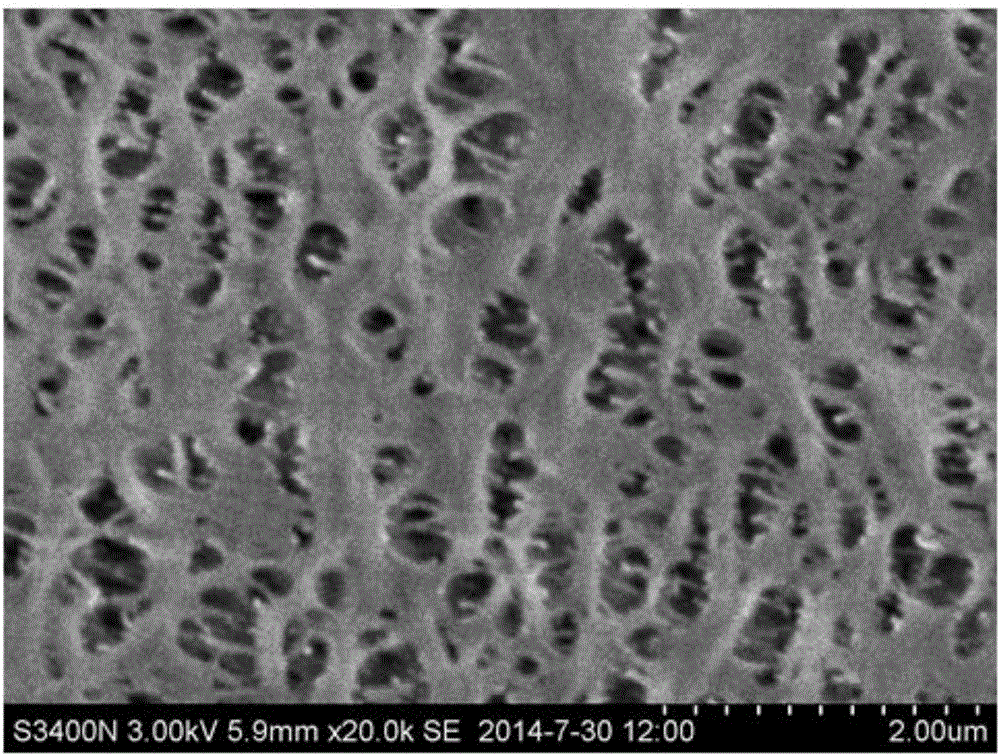

Embodiment 1

[0028] Add polyphenylene sulfide resin with a melt index of 0.1g / 10min to an extrusion casting machine, and melt extrusion casting to obtain a polyphenylene sulfide initial film. The melt extrusion temperature is 304°C, and the initial film is drummed at 140°C After heat treatment in air oven for 0.5h, stretch at 80°C at a speed of 10mm / min to 5% deformation, then at 130°C at a speed of 50mm / min to 40% deformation, heat setting temperature 140°C, The heat-setting time is 3 minutes, and a polyphenylene sulfide microporous membrane with a porosity of 20% is obtained, and the structure is good.

Embodiment 2

[0030] Add the polyphenylene sulfide resin with a melt index of 5g / 10min to the extrusion casting machine, and melt extrusion casting to obtain the initial polyphenylene sulfide film. The melt extrusion temperature is 310°C, and the initial film is blown at 200°C After heat treatment in the oven for 8 hours, stretch at 100°C at a speed of 30mm / min to a deformation of 40%, and then stretch at a speed of 80mm / min at 190°C to a deformation of 120%, heat setting temperature 210°C, heat setting After 10 minutes, a polyphenylene sulfide microporous membrane with a porosity of 60% was obtained, and the structure was good.

Embodiment 3

[0032] Add the polyphenylene sulfide resin with a melt index of 3g / 10min to the extrusion casting machine, and melt extrusion casting to obtain the initial film of polyphenylene sulfide. The melt extrusion temperature is 320°C, and the initial film is blown at 210°C After heat treatment in the oven for 2 hours, stretch at 80°C at a speed of 30mm / min to a deformation of 5%, and then at 200°C at a speed of 60mm / min to a deformation of 120%, heat setting temperature 210°C, heat setting After 10 minutes, a polyphenylene sulfide microporous membrane with a porosity of 50% was obtained, and the structure was good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com