Preparation method for nanometer oxide-supported lithium phosphate catalyst for pilot-scale reaction

A nano-oxide, lithium phosphate technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems affecting the large-scale industrial production of gas-phase isomerization of propylene oxide and the selection of unstable products. It can solve the problems of good catalytic isomerization reaction activity, enhanced strength and tolerance, and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

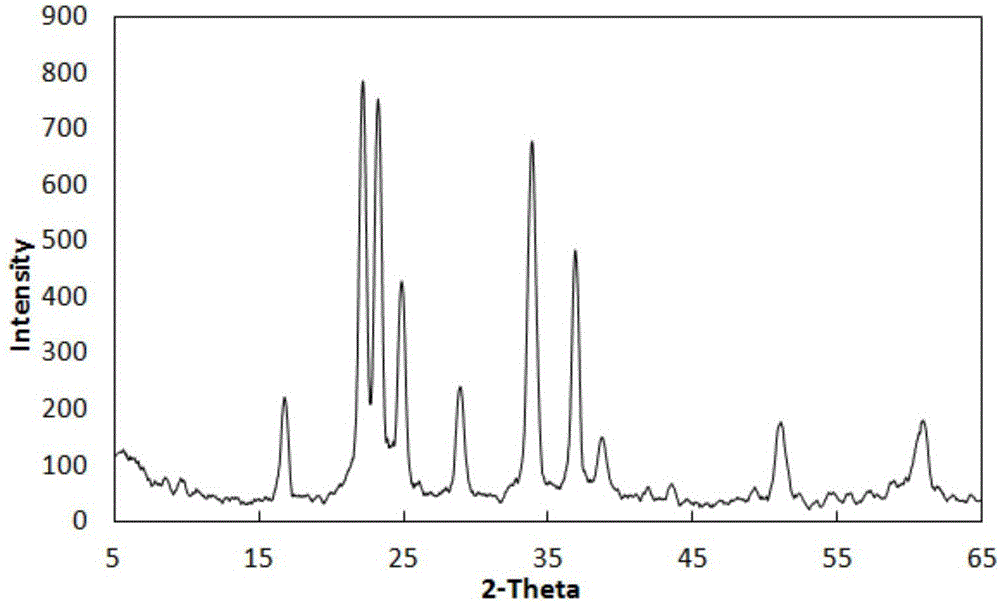

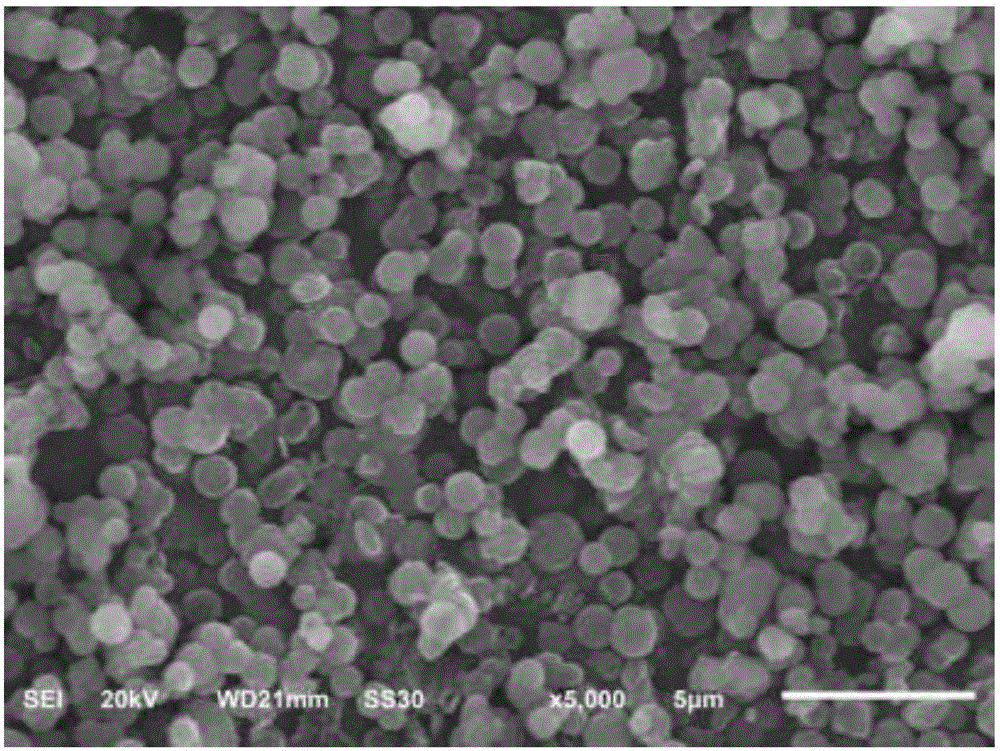

Embodiment 1

[0033] Weigh 68.4g of sodium phosphate (0.18mol Na 3 PO 4 12H 2 O) and 30.1g lithium hydroxide (0.72mol LiOH·H 2 O), in molar ratio n(Na 3 PO 4 ):n(LiOH)=1:4, respectively add hot water of 65°C and stir evenly until dissolving to obtain sodium phosphate solution, lithium hydroxide solution (the molar concentration of sodium phosphate solution is 0.5mol / L, the molar concentration of lithium hydroxide solution Concentration is 2.16mol / L); Simultaneously turn on the ultrasonic device (ultrasonic vibration frequency is 50Hz, heating temperature is 65 ℃) and high-speed shearing machine (high-speed shearing speed is 4.0Kr / min), then sodium phosphate solution and hydroxide Lithium solution was quickly and simultaneously added to the ultrasonic reaction device, poured out in 30 seconds, and the mixed solution was stirred and reacted for 2 hours to obtain the reaction product I; then the obtained reaction product I was subjected to aging treatment for 3 hours, and the aged solution...

Embodiment 2

[0036] Weigh 68.4g of sodium phosphate (0.18mol Na 3 PO 4 12H 2 O) and 22.7g lithium hydroxide (0.54mol LiOH·H 2 O), in molar ratio n(Na 3 PO 4 ):n(LiOH)=1:3, respectively add hot water of 65°C and stir evenly until dissolving to obtain sodium phosphate solution, lithium hydroxide solution (the molar concentration of sodium phosphate solution is 0.8mol / L, the molar concentration of lithium hydroxide solution Concentration is 3.0mol / L); Simultaneously open ultrasonic device (ultrasonic vibration frequency is 50Hz, heating temperature is 50 ℃) and high-speed shearing machine (high-speed shearing speed is 4.0Kr / min), then sodium phosphate solution and hydroxide The lithium solution was quickly and simultaneously added to the ultrasonic reaction device in parallel, poured out in 30 seconds, and the mixed solution was stirred and reacted for 3 hours to obtain the reaction product I; then the obtained reaction product I was aged for 2 hours, and the aged solution Carry out suct...

Embodiment 3

[0039] Weigh 68.4g of sodium phosphate (0.18mol Na 3 PO 4 12H 2 O) and 37.8g lithium hydroxide (0.9mol LiOH·H 2 O), in molar ratio n(Na 3 PO 4 ):n(LiOH)=1:5, add hot water of 65 ℃ and stir evenly until dissolving to obtain sodium phosphate solution, lithium hydroxide solution (the molar concentration of sodium phosphate solution is 0.72mol / L, the molar concentration of lithium hydroxide solution Concentration is 3.6mol / L); Simultaneously turn on the ultrasonic device (ultrasonic vibration frequency is 50Hz, heating temperature is 70 ℃) and high-speed shearing machine (high-speed shearing speed is 5.0Kr / min), then sodium phosphate solution and hydroxide Lithium solution was quickly and simultaneously added to the ultrasonic reaction device, poured out in 30 seconds, and the mixture was stirred and reacted for 2 hours to obtain the reaction product I; then the reaction product I was subjected to aging treatment for 2 hours; the aged solution was reduced Suction filtration a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com