A kind of modified cotton fiber for infants and young children based on ionic liquid and preparation method thereof

A technology for ionic liquids and infants, which is applied in fiber processing, plant fibers, textiles and papermaking, etc., can solve the problems of not being suitable for infants and children's clothing and cannot be separated, and achieve the effect of improving durability and adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

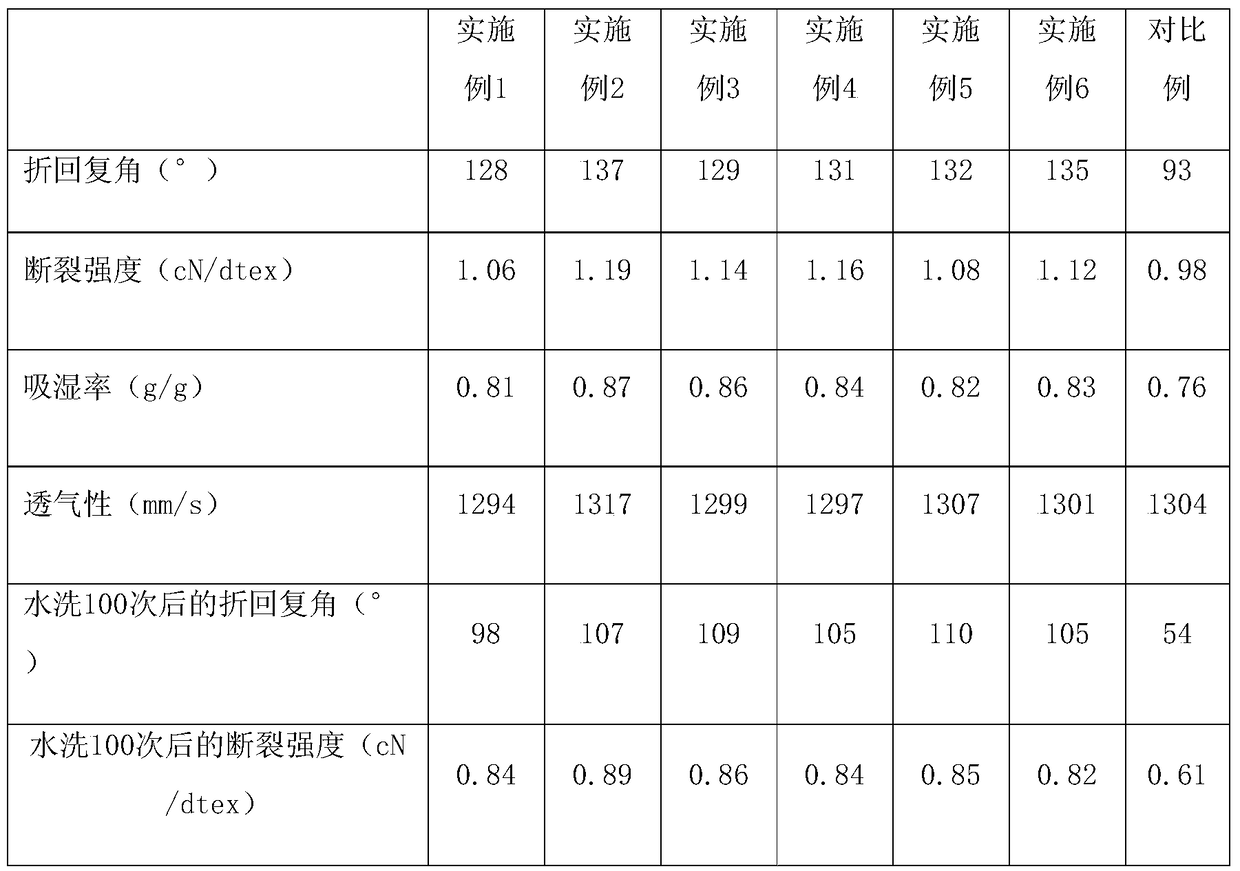

Examples

Embodiment 1

[0030] (1) Remove the impurities on the surface of the cotton fibers, clean them up, and ball mill them with a speed of 100rpm / min for 2min to obtain pre-opened cotton fibers, and treat the pre-opened cotton fibers with low-temperature oxygen plasma for 30s at a power of 100W, A surface-activated cotton fiber is obtained.

[0031] (2) In parts by weight, put 1 part of scattered cotton in 15 parts of ionic liquid solution, heat and stir in a water bath at 85°C until completely dissolved, then add 0.5 part of waste silk, and continue heating and stirring in a water bath at 85°C After completely dissolving, add 3 parts of β-cyclodextrin modified starch, stir well, and filter to obtain a mixed solution of cellulose protein, wherein the crystallinity of cellulose is 75%, and the molecular weight of silk protein is 12500Da.

[0032] (3) Immerse the surface-activated cotton fiber prepared in step (1) in the cellulose protein mixed solution prepared in step (2), bath ratio 1:30, soak ...

Embodiment 2

[0034] (1) Remove the impurities on the surface of the cotton fibers, clean them up, and ball mill them for 5 minutes at a speed of 200rpm / min to obtain pre-opened cotton fibers, and treat the pre-opened cotton fibers with low-temperature oxygen plasma for 50s at a power of 150W. A surface-activated cotton fiber is obtained.

[0035] (2) In parts by weight, put 1 part of scattered cotton in 25 parts of ionic liquid solution, heat and stir in a water bath at 95°C until completely dissolved, then add 0.8 part of waste silk, and continue heating and stirring in a water bath at 95°C After completely dissolving, add 6 parts of β-cyclodextrin modified starch, stir well, and filter to obtain a mixed solution of cellulose protein, wherein the crystallinity of cellulose is 55%, and the molecular weight of silk protein is 1800Da.

[0036] (3) Immerse the surface-activated cotton fiber prepared in step (1) in the cellulose protein mixed solution prepared in step (2), bath ratio 1:50, soa...

Embodiment 3

[0038] (1) Remove the impurities on the surface of the cotton fiber, clean it up, and process it by ball milling at a speed of 150rpm / min for 3min to obtain pre-opened cotton fibers, and treat the pre-opened cotton fibers with low-temperature oxygen plasma for 40s at a power of 120W, A surface-activated cotton fiber is obtained.

[0039] (2) In parts by weight, put 1 part of loose cotton in 20 parts of ionic liquid solution, heat and stir in a water bath at 90°C until completely dissolved, then add 0.7 part of waste silk, and continue heating and stirring in a water bath at 90°C After completely dissolving, add 5 parts of β-cyclodextrin modified starch, stir well, and filter to obtain a mixed solution of cellulose protein, wherein the crystallinity of cellulose is 60%, and the molecular weight of silk protein is 2000Da.

[0040] (3) Immerse the surface-activated cotton fiber prepared in step (1) in the cellulose protein mixed solution prepared in step (2), bath ratio 1:40, imm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com