Fungus solid fermentation medium

A solid fermentation, culture medium technology, applied in fermentation, microorganism-based methods, microorganisms, etc., can solve problems such as product activity decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

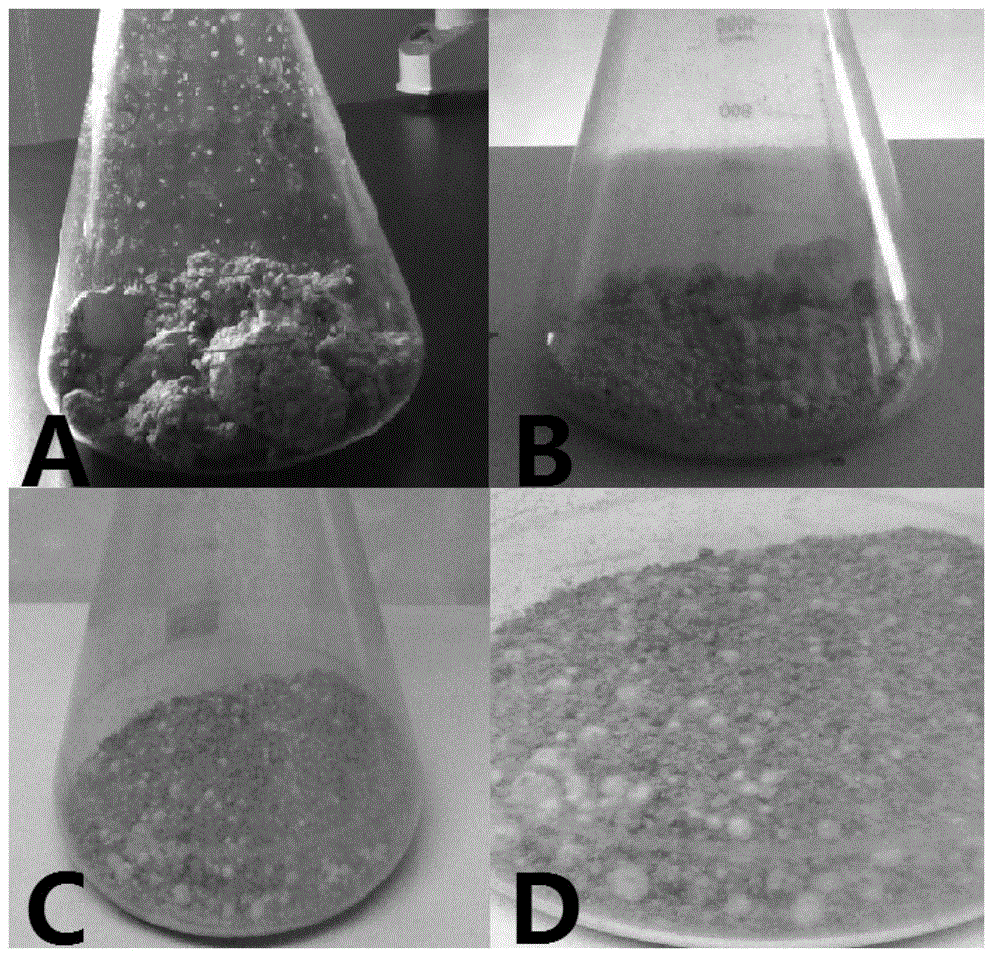

[0041] Embodiment 1: the determination of solid fermentation medium water content

[0042] In solid fermentation, the water content of the medium will affect the growth of microorganisms. If the water content is too high, agglomerates will be formed during the cultivation process, thereby affecting the progress of fermentation. In this embodiment, the water content of the culture medium is changed by changing the ratio of material to water between raw millet and potato juice and the amount of potato juice in the nutrient solution in the preparation of cooked millet.

[0043] According to the above design theory, on the basis of a large number of preliminary selection of medium, the following three medium formulations were selected for experiments to determine the optimal water content in the medium.

[0044] The solid fermentation medium of formula 1 consists of the following ingredients: 100g of cooked millet, 20g of perlite, and 25ml of nutrient solution.

[0045] The prepa...

Embodiment 2

[0071] Embodiment 2: the optimization of solid fermentation medium formula

[0072] The medium used is a solid fermentation medium with a determined water content, and its formula is as in formula three in Example 1.

[0073] The optimization of the medium adopts an orthogonal design. As shown in Table 1, the amount of glucose is factor one, the amount of peptone is factor two, the amount of low-temperature defatted soybean powder is factor three, and the amount of potassium dihydrogen phosphate is factor four. An orthogonal design with 4 factors and 3 levels was carried out. The factors and levels, and the orthogonal design table are shown in Table 2:

[0074] Table 1: Orthogonal design table with 4 factors and 3 levels (unit: gram):

[0075] level\factor

glucose

Peptone

Low temperature defatted soybean flour

Potassium dihydrogen phosphate

level 1

0.50

1.00

1.00

0.05

level 2

3.00

4.00

4.00

0.30

l...

Embodiment 3

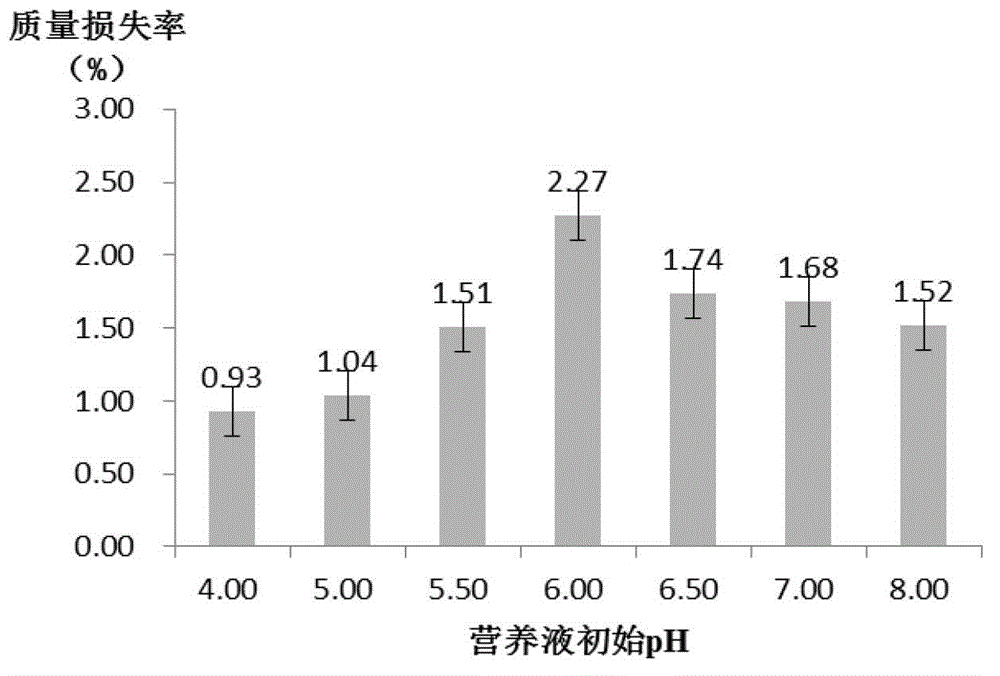

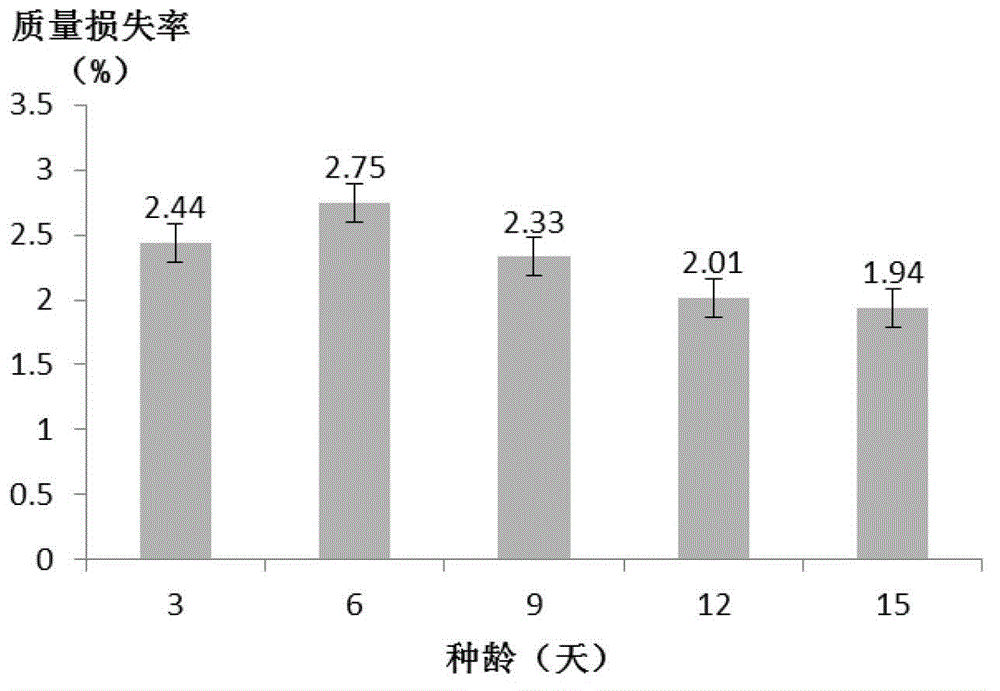

[0093] Embodiment 3, optimum pH of nutrient solution in solid fermentation medium

[0094] In the solid fermentation medium, glucose, low-temperature defatted soybean powder, peptone, potassium dihydrogen phosphate and magnesium sulfate are dissolved in potato juice to prepare the nutrient solution part of the medium, and the nutrient solution will be mixed into cooked millet and perlite In the granular system composed of it, it becomes an important part of the culture medium. A single factor test was performed on the initial pH of the nutrient solution.

[0095] In this example, NaOH solution (5 mol / L) and hydrochloric acid solution (analytical grade hydrochloric acid and pure water in a volume ratio of 1:1) were used to adjust the pH of the nutrient solution. Set 7 groups of different pH treatments, namely 4, 5, 5.5, 6, 6.5, 7, and 8. Three parallel experiments were carried out for each treatment group, and each group was controlled by the blank medium not inoculated with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com