Method for Extracting Flavonoids with Antioxidant Activity and 3,4',7-Trihydroxydihydroflavonol from Sumac Flour

A technology of trihydroxy dihydroflavonol and antioxidant activity, applied in the directions of organic chemistry, antidote, drug combination, etc., can solve problems such as weak utilization of lacquer seeds, and achieve light color, easy implementation, and improved extraction yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

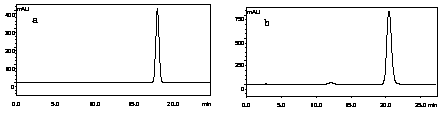

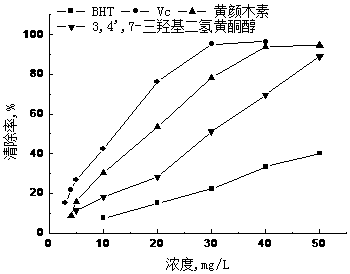

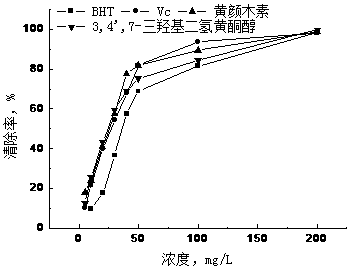

Image

Examples

Embodiment 1

[0030] first step

[0031] Dry and remove slag from lacquer tree powder, add ethanol aqueous solution with a mass fraction of 50-95% according to the mass volume ratio of 1:10-1:30 (g:mL), and extract under reduced pressure for 2-3 times, each time 1~3h, filter, combine the filtrates, evaporate under reduced pressure at 40~60°C to remove the solvent, and obtain the aqueous crude extract;

[0032] second step

[0033] Add distilled water to the crude extract at a mass ratio of 1:3~1:10 (g:mL), stir to dissolve, add petroleum ether to extract 1~5 times, separate, and evaporate the solvent under reduced pressure at 40~60°C to obtain petroleum ether Extract; the aqueous layer was extracted 1 to 5 times with ethyl acetate, separated, evaporated under reduced pressure at 40 to 60°C to remove the solvent, and dried to obtain the ethyl acetate extract;

[0034] third step

[0035] Adsorb the ethyl acetate extract and silica gel filler at a mass ratio of 1:15-50, the column length i...

Embodiment 2

[0042] first step

[0043] Dry the lacquer wood powder and remove the slag. According to the mass volume ratio of 1:10~1:30 (g:mL), add methanol aqueous solution with a mass fraction of 50~95%, extract 2~3 times under reduced pressure and reflux, each time 1~3h, filter, combine the filtrates, evaporate under reduced pressure at 40~60°C to remove the solvent, and obtain the aqueous crude extract;

[0044] second step

[0045] Add distilled water to the crude extract at a mass ratio of 1:3~1:10 (g:mL), stir to dissolve, add petroleum ether to extract 1~5 times, separate, and evaporate the solvent under reduced pressure at 40~60°C to obtain petroleum ether Extract; the aqueous layer was extracted 1 to 5 times with ethyl acetate, separated, evaporated under reduced pressure at 40 to 60°C to remove the solvent, and dried to obtain the ethyl acetate extract;

[0046] third step

[0047] Adsorb the ethyl acetate extract and silica gel filler at a mass ratio of 1:15-50, the column ...

Embodiment 3

[0051] first step

[0052] Dry and remove slag from lacquer tree powder, add ethanol aqueous solution with a mass fraction of 50-95% according to the mass volume ratio of 1:10-1:30 (g:mL), and extract under reduced pressure for 2-3 times, each time 1~3h, filter, combine the filtrates, evaporate under reduced pressure at 40~60°C to remove the solvent, and obtain the aqueous crude extract;

[0053] second step

[0054] Add distilled water to the crude extract at a mass ratio of 1:3~1:10 (g:mL), stir to dissolve, add petroleum ether to extract 1~5 times, separate, and evaporate the solvent under reduced pressure at 40~60°C to obtain petroleum ether Extract; the aqueous layer was extracted 1 to 5 times with ethyl acetate, separated, evaporated under reduced pressure at 40 to 60°C to remove the solvent, and dried to obtain the ethyl acetate extract;

[0055] third step

[0056] Adsorb the ethyl acetate extract and silica gel filler at a mass ratio of 1:15-50, the column length i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com