Aluminum alloy conductor wire, aluminum alloy twisted wire, sheathed electrical cable, wire harness, and method for manufacturing aluminum alloy conductor wire

A technology of aluminum alloy wires and manufacturing methods, which is applied in the direction of metal/alloy conductors, cable/conductor manufacturing, conductive materials, etc., can solve the problems of wire plastic deformation deviation, insufficient crimping reliability, abnormal growth of grains, etc., Achieve good strength, ensure strength, and achieve uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0079] The present invention will be described in detail based on the following examples. In addition, this invention is not limited to the Example shown below.

[0080] (Example, comparative example)

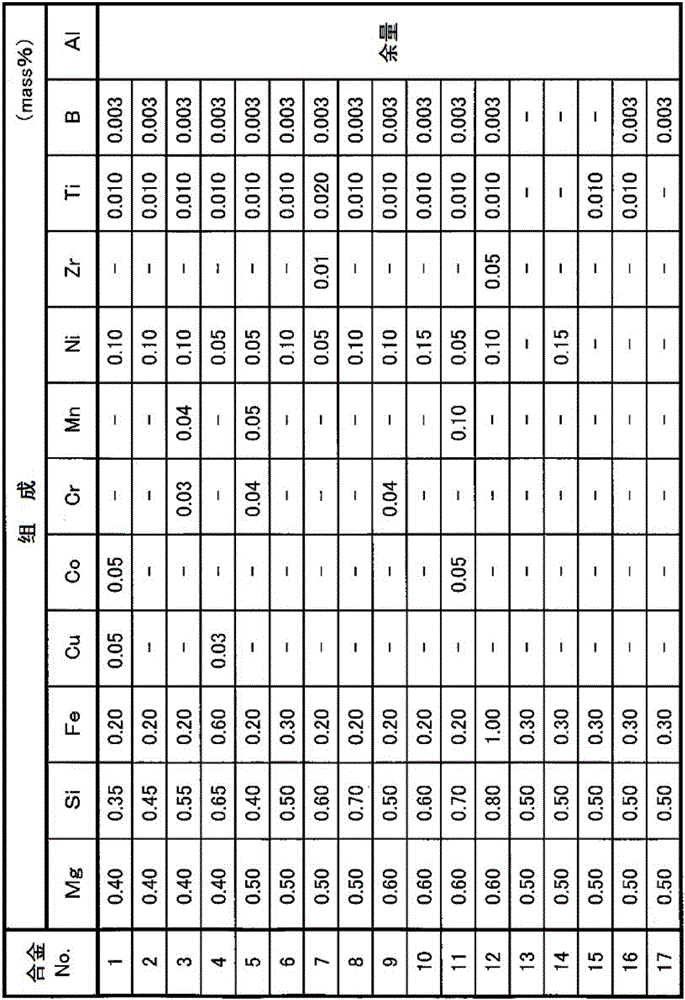

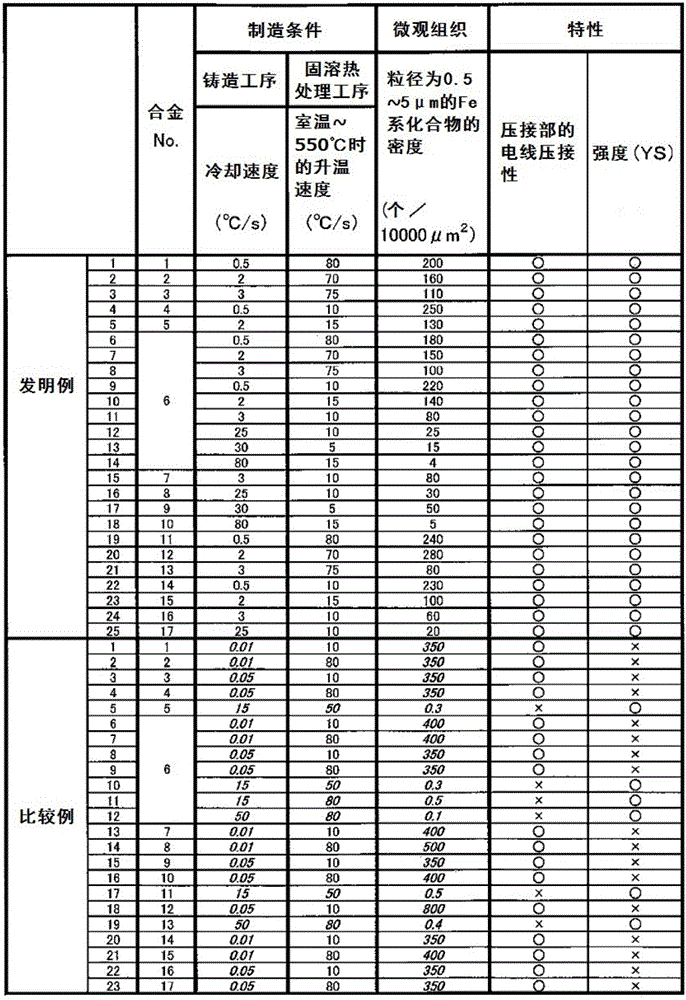

[0081] Mg, Si, Fe, and Al, and optionally added Ti, B, Mn, Cr, Cu, Co, Ni, and Zr were fed in such a way as to achieve the contents (mass %) shown in Table 1, using Propez The continuous casting and rolling machine is a water-cooled mold that continuously casts and rolls molten metal to produce rods of about 9.5mmφ. The cooling rates during casting at this time were set to the values shown in Table 2, respectively. The first wire drawing process is performed on this bar material so that a predetermined degree of processing can be obtained. Next, the workpiece subjected to the first wire drawing is subjected to the first heat treatment at 300° C. to 480° C. for 0.05 hours to 6 hours, and then the second wire drawing is performed until the wire diameter reaches 0.31 mmφ. Ne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com