An automobile exhaust air temperature difference power generation system, its cooling method and the method for controlling the exhaust gas flow

A technology of thermoelectric power generation and automobile exhaust, applied in the direction of flow control of electric devices, flow control, non-electric variable control, etc., can solve problems such as damage, and achieve the effect of water cooling system control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

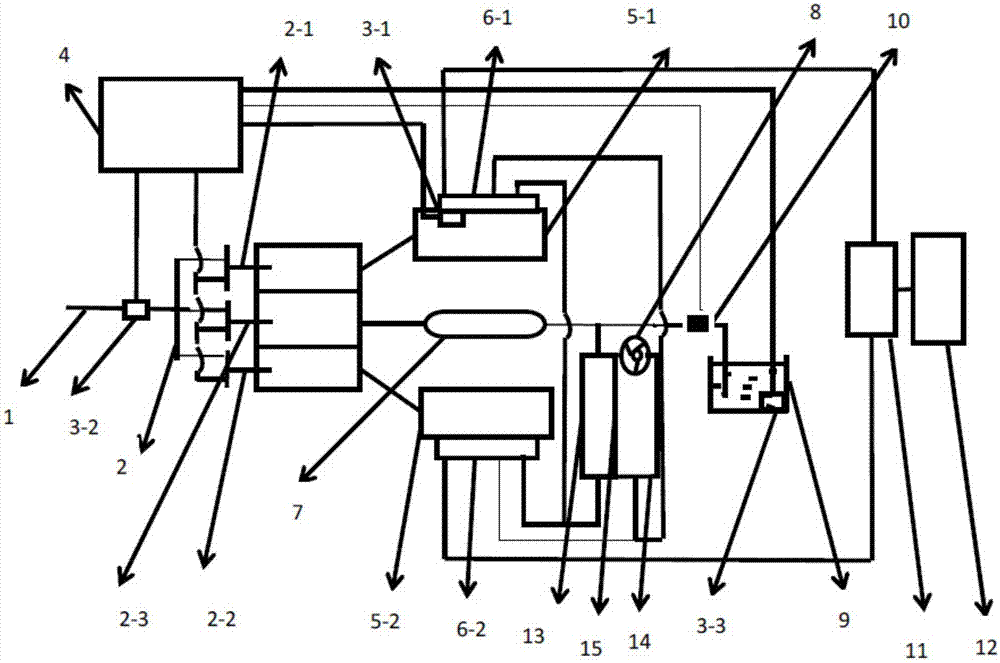

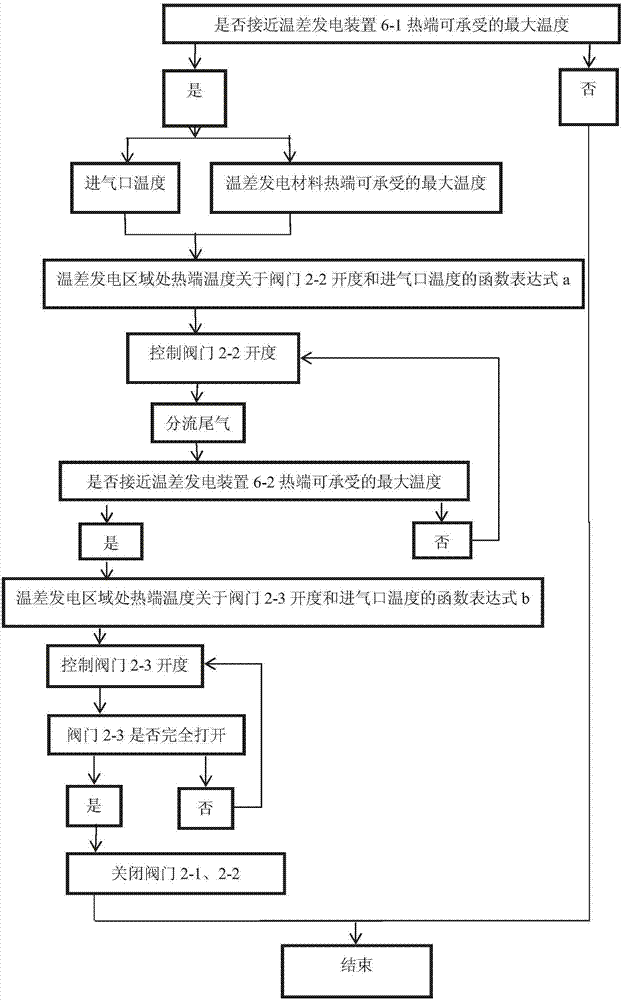

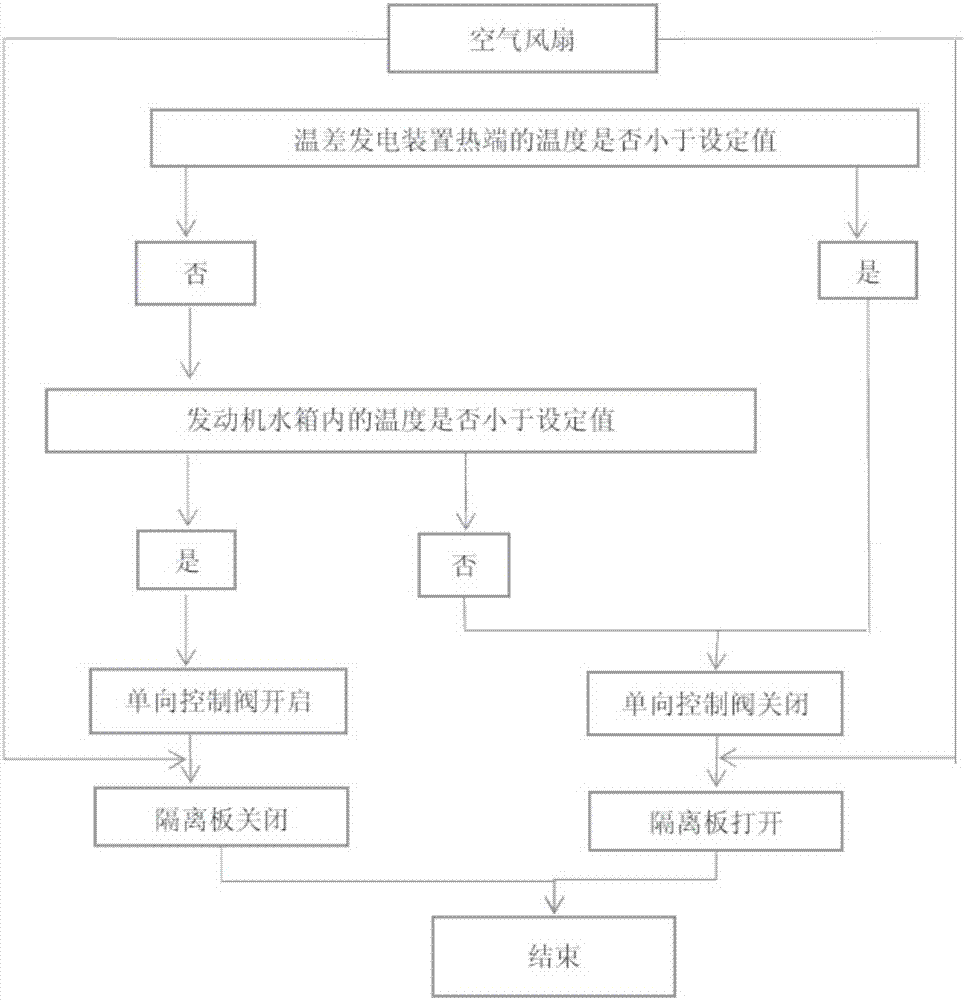

[0023] Such as figure 1 As shown, a novel automobile exhaust temperature difference power generation system of the present invention includes a heat collection system, a thermoelectric power generation device, a cooling system, a temperature protection system, a DC-DC control system, and a storage battery.

[0024] The inlet end of the three-position four-way valve 2 is connected to the exhaust pipe 1, and valve A, valve B, and valve C are respectively connected to the heat collector A, heat collector B, and condenser pipe 7, and are installed in the exhaust pipe for three-way catalysis The position between the condenser and the muffler; the condensation pipe 7 is on the same straight line as the automobile exhaust pipe, and the heat collector A and the heat collector B are installed symmetrically about the condensation pipe 7 and at 30°.

[0025] The hot end of thermoelectric generator 6 (comprising thermoelectric generator A and thermoelectric generator B) is attached to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com