a mn 4+ Activated polyfluoride red luminescent material and preparation method

A polyfluoride, red light-emitting technology, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problem that there are not many reports on polyfluorine compound phosphors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Weigh barium carbonate: 1.97 g, hafnium dioxide: 1.052 g, potassium hexafluoromanganate: 0.062 g, then add 15 mL (40%) hydrofluoric acid (HF) to the above solid mixture and stir to dissolve, then add 35 mL distilled water. Subsequently, the resulting solution was reacted in an autoclave at 180°C for 10 hours, cooled to room temperature, washed with distilled water, and then dried in a vacuum oven for 24 hours, and finally the white powder obtained was the final Ba 2 Hf 8 :Mn 4+ Luminescent material.

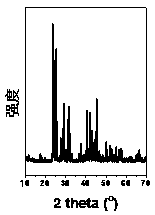

[0015] attached figure 1 Shown is the XRD diffraction pattern of this phosphor, which is consistent with the standard card JCPDS 52-0096 (Ba 2 Hf 8 ) are basically consistent, which indicates that the structure of our synthesized sample is similar to that of Ba 2 Hf 8 unanimous.

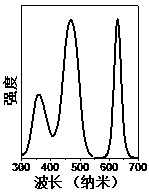

[0016] attached figure 2 Shown are the room temperature excitation spectrum (monitored at 627 nm) and emission spectrum (excited at 465 nm) of the sample. The sample has strong broadba...

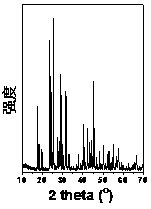

Embodiment 2

[0018] Weigh barium carbonate: 0.996 g, hafnium dioxide: 1.052 g, potassium hexafluoromanganate: 0.124 g, then add 10 mL (40%) hydrofluoric acid (HF) to the above solid mixture and stir to dissolve, then add 40 mL distilled water. Subsequently, the resulting solution was reacted in an autoclave at 160°C for 12 hours, cooled to room temperature, washed with distilled water, and then dried in a vacuum oven for 24 hours. Finally, the white powder obtained was the final Ba 2 Hf 8 :Mn 4+ Luminescent material.

Embodiment 3

[0020] Weigh barium fluoride: 0.875 g, hafnium dioxide: 0.999 g, potassium hexafluoromanganate: 0.186 g, then add 5 mL (40%) hydrofluoric acid (HF) to the above solid mixture and stir to dissolve, then add 45 mL of distilled water. Subsequently, the resulting solution was reacted in an autoclave at 120°C for 8 hours, cooled to room temperature, washed with distilled water, and then dried in a vacuum oven for 24 hours. Finally, the white powder obtained was the final Ba 2 Hf 8 :Mn 4+ Luminescent material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com