Low temperature gel breaking viscosity reducer of crosslinked guar gum backflow fracturing fluid, and preparation method thereof

A technology of fracturing flowback fluid and cross-linked guar gum, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problem of unconsidered gel breaking and viscosity reduction treatment cost, high processing cost, and low temperature gel breaking. Viscosity reduction literature and other issues, to achieve the effect of reducing solubility and hydrodynamic size, low cost, and reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

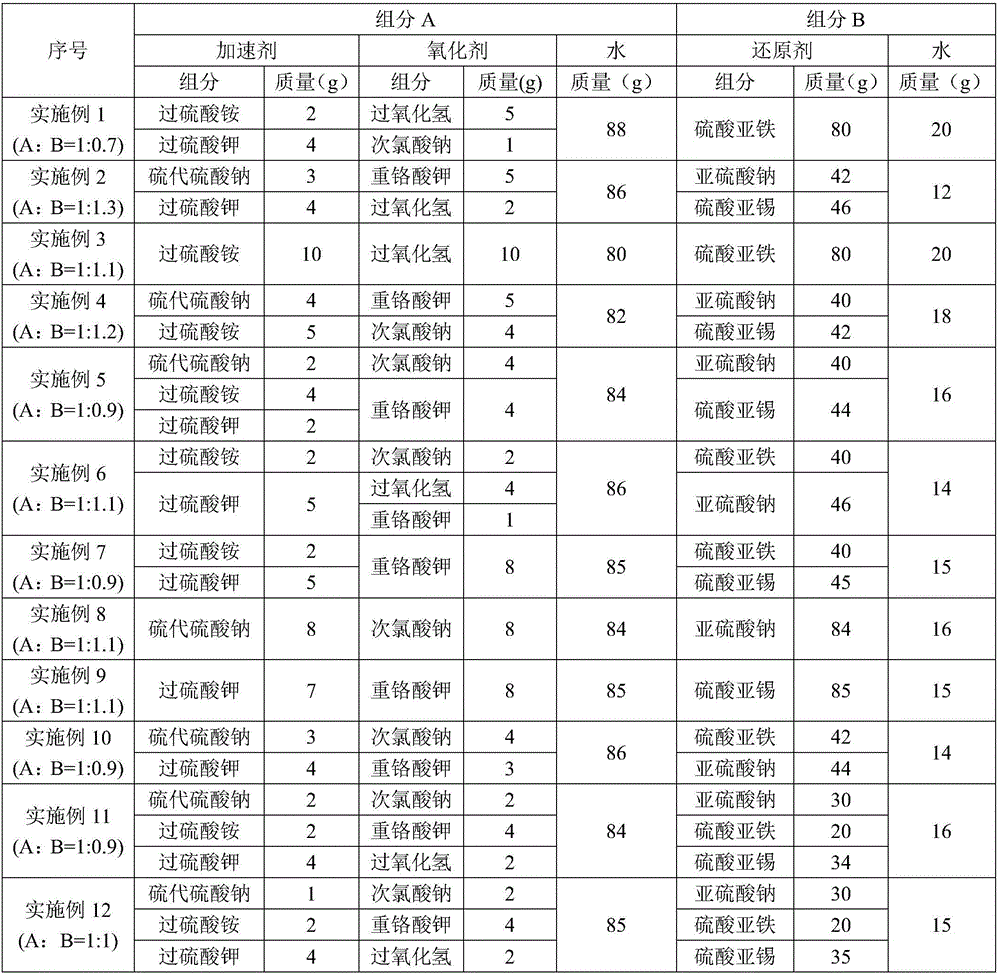

[0036] The preparation method of the cross-linked guar gum fracturing flowback fluid of the present invention has the following steps:

[0037] 1) Preparation of component A:

[0038] Weigh the accelerator and the oxidant according to the proportion of parts by mass, and add them to the water in sequence at a stirring rate of 60-90 rpm to fully dissolve and react for 3-5 minutes to obtain component A, which is sealed for later use;

[0039] 2) Preparation of component B:

[0040] Weigh the reducing agent and dissolve it in water according to the mass parts ratio, and stir for 2-4 min at a stirring rate of 60-90 rpm to fully dissolve it to obtain component B, which is sealed for later use;

[0041] 3) Mixed reaction:

[0042] Mix Component A and Component B according to the mass ratio A:B=1:0.7-1.3, and react for 3-5min at a stirring rate of 90-120rpm to obtain the low-temperature gel breaking of the cross-linked guar gum fracturing flowback fluid. Adhesive. In the above technical solut...

Embodiment 1

[0047] The preparation method of the low-temperature gel breaking and viscosity reducing agent of this embodiment is as follows:

[0048] Preparation of component A: Weigh 6g accelerator (2g ammonium persulfate, 4g potassium persulfate) and 6g oxidant (5g hydrogen peroxide, 1g sodium hypochlorite), and add them to 88g water at a stirring rate of 60rpm. Fully dissolve and react for 3 minutes, and seal for later use.

[0049] Preparation of component B: Weigh 80 g of reducing agent (ferrous sulfate) and dissolve it in 20 g of water, stir at 60 rpm for 3 minutes to fully dissolve it, and seal it for later use.

[0050] Mixing reaction: Component A and component B are mixed according to the mass ratio A:B=1:0.7, and reacted for 3min under the conditions of stirring speed of 90rpm and temperature of 5℃ to obtain crosslinked guar gum fracturing flowback fluid Low temperature gel breaking and viscosity reducing agent.

[0051] Take 100g of a well high-viscosity (viscosity 4.4mPa.s) cross-li...

Embodiment 2

[0053] The preparation method of the low-temperature gel breaking and viscosity reducing agent of this embodiment is as follows:

[0054] Preparation of component A: Weigh 7g accelerator (3g sodium thiosulfate, 4g potassium persulfate) and 7g oxidant (5g potassium dichromate, 2g hydrogen peroxide), and add to 86g at 80rpm stirring speed. Dissolve and react for 4 minutes in water, and seal for later use.

[0055] Preparation of component B: Weigh 88g reducing agent (42g sodium sulfite, 46g stannous sulfate) and dissolve it in 12g water, stir at 90rpm for 4min to make it fully dissolved, and seal it for later use.

[0056] Mixing reaction: Mix component A and component B according to the mass ratio A:B=1:1.3, and react for 5 minutes at a stirring rate of 110rpm and a temperature of 10°C to obtain a cross-linked guar gum fracturing flowback fluid Low temperature gel breaking and viscosity reducing agent.

[0057] Take 100g of a well high-viscosity (viscosity 5.6mPa.s) cross-linked guar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com