A pressure-sensitive adhesive tape capable of reducing viscosity through thermal expansion and a preparing method thereof

A technology of pressure-sensitive adhesive tapes and pressure-sensitive adhesives, applied in the direction of adhesives, adhesive types, pressure-sensitive films/sheets, etc., can solve the problem of narrow use range of expandable adhesive tapes, and achieve the consistency of curling direction And regularity, the effect of reducing battery space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The application of the present invention provides a pressure-sensitive adhesive tape of thermal expansion and loss-of-tack type, which is made of the following components in mass percentage:

[0044] 1) Polyurethane pressure-sensitive adhesive 40.4%;

[0045] 2) Azo compounds 33.5%;

[0046] 3) 1.6% isocyanate curing agent;

[0047] 4) Titanium blue 4.5%;

[0048] 5) Ethyl acetate 20%.

[0049] The base film suitable for the pressure-sensitive adhesive tape has a thickness of 6um, and the base film is polyester or polyurethane pressure-sensitive adhesive with a thickness of 15um.

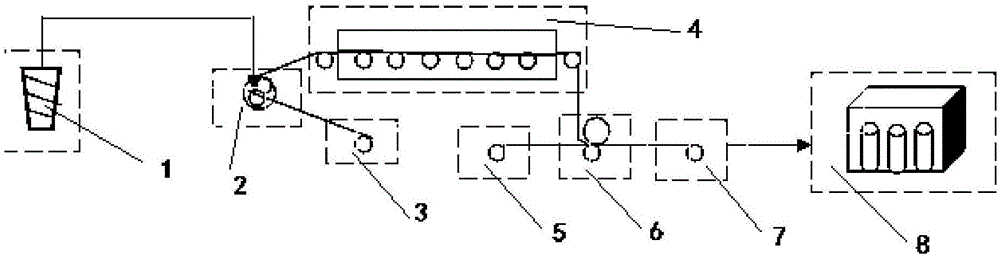

[0050] Such as figure 1 As shown, the manufacturing method of the heat-expandable and viscous-losing pressure-sensitive adhesive tape described in the application of the present invention sequentially passes through the rubber material configuration area 1, the transfer type blade coater 2, the unwinding area 3 of the film to be coated, and the baking process. Oven area 4, laminating bas...

Embodiment 2

[0059] The application of the present invention provides a pressure-sensitive adhesive tape of thermal expansion and loss-of-tack type, which is made of the following components in mass percentage:

[0060] 1) Epoxy pressure sensitive adhesive 66%;

[0061] 2) 15% benzenesulfonyl hydrazide;

[0062] 3) Amino resin curing agent 1%;

[0063] 4) Titanium dioxide 3%;

[0064] 5) Butyl acetate 15%.

[0065] The base film suitable for the heat-expandable tack-losing pressure-sensitive adhesive tape has a thickness of 36um, and the base film is a polyimide film with a thickness of 50um.

[0066] The manufacturing method of the above-mentioned heat-expandable and viscous-losing pressure-sensitive adhesive tape comprises the following steps:

[0067] A. Mix epoxy pressure-sensitive adhesive, benzenesulfonyl hydrazide, amino resin curing agent, titanium dioxide and butyl acetate according to the above ratio, and stir for 15 minutes at a speed of 1500r / min under a high-speed mixer to...

Embodiment 3

[0074] The application of the present invention provides a pressure-sensitive adhesive tape of thermal expansion and loss-of-tack type, which is made of the following components in mass percentage:

[0075] 1) Polyester pressure-sensitive adhesive 50%;

[0076] 2) Carbonate compound 30%;

[0077] 3) Aziridine curing agent 1%;

[0078] 4) Cobalt green 3%;

[0079] 5) Toluene 16%.

[0080] Further, the applicable base film of the heat-expandable tack-losing pressure-sensitive adhesive tape is a polyolefin film with a thickness of 20 um and a thickness of 30 um.

[0081] The manufacturing method of the above-mentioned heat-expandable and viscous-losing pressure-sensitive adhesive tape comprises the following steps:

[0082] A. Mix polyester pressure-sensitive adhesive, carbonate compound, aziridine curing agent, cobalt green and toluene according to the above ratio, and stir for 30 minutes at a speed of 800r / min under a high-speed mixer to obtain an adhesive;

[0083] B. Set...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com