A kind of preparation method of porous polyethylene film

A polyethylene film and membrane technology, which is applied in the field of materials, can solve the problems of restricting the use of polyethylene porous membranes and the inability to continuously adjust the thickness and pore size of polyethylene porous membranes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

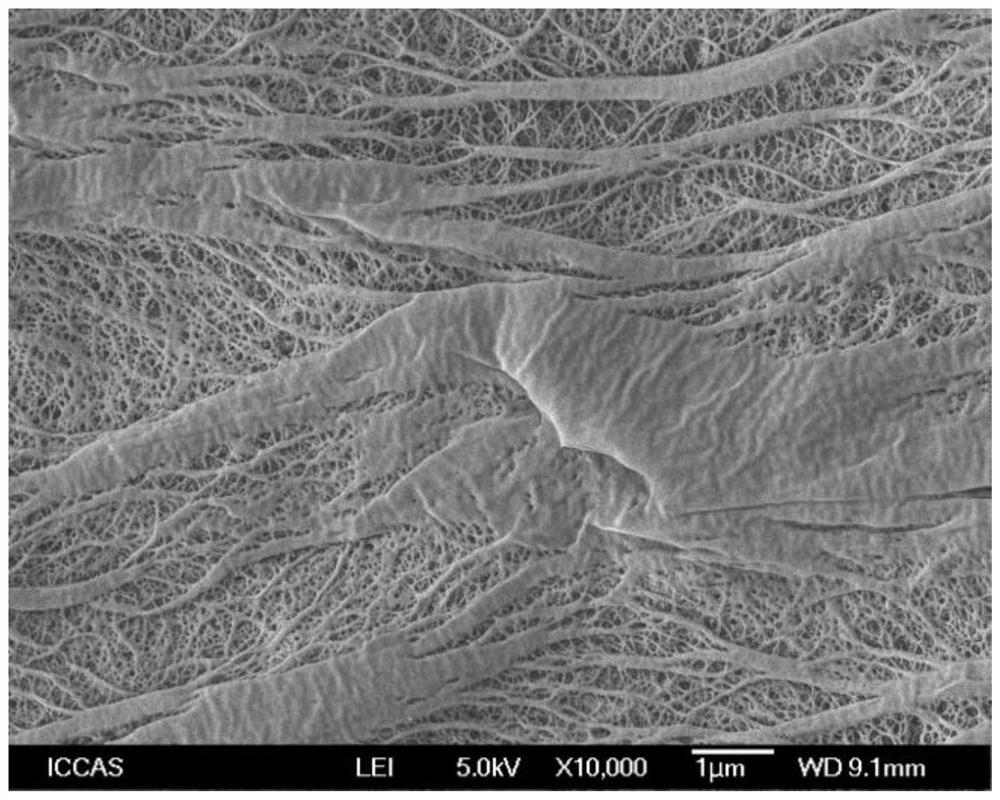

[0028] The embodiment of the present invention discloses a method for preparing a porous polyethylene film, which includes the following steps: mixing polyethylene with a mass ratio of 1 to 10:1 and a pore-forming agent to obtain a first mixture, and the pore-forming agent includes poly Ethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer; the first mixture is melt-mixed in an internal mixer to obtain a mixed melt, and the temperature of melt-mixing is 170-230°C , the time for melting and mixing is 2 to 30 minutes; the mixed melt is subjected to high-temperature compression molding to obtain a diaphragm; the diaphragm is cooled to remove the pore-forming agent in the diaphragm; the diaphragm is placed in a two-way Stretching in a stretching machine, heat setting and slow cooling to obtain a porous polyethylene film, the stretching temperature is 50-130°C, and the heat setting temperature is 80-130°C.

[0029] As a preferred solution, the polyethylene includ...

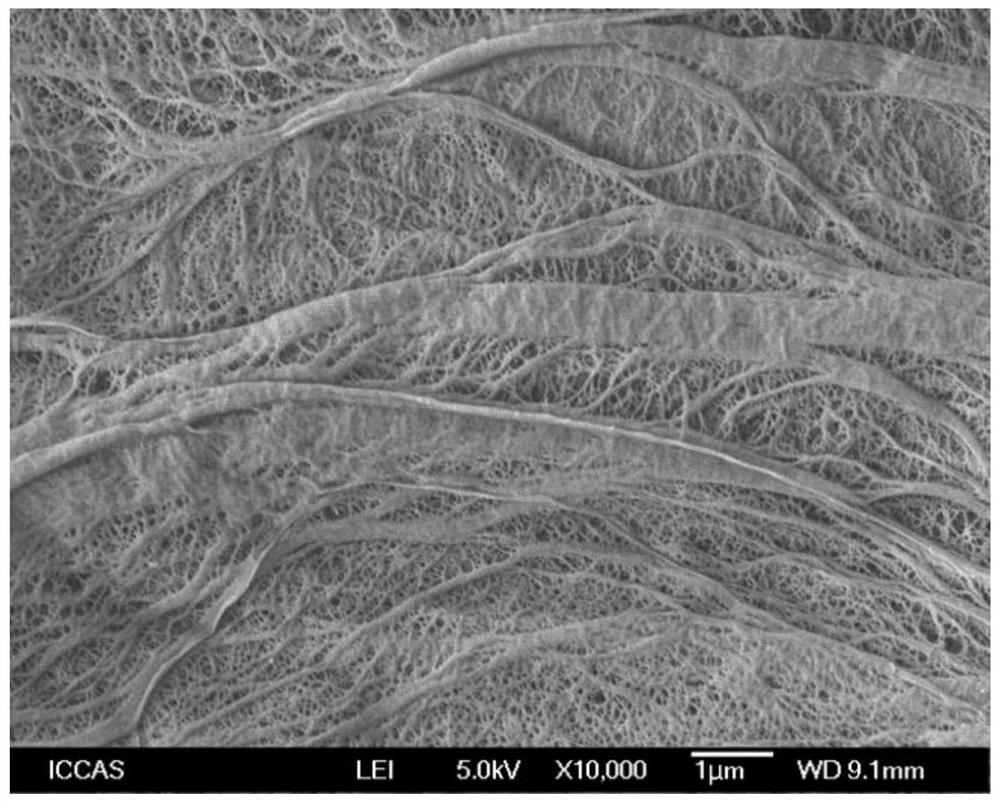

Embodiment 1

[0041] Add 5.0 grams of polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer F127 to 45.0 grams of low-density polyethylene (LDPE) powder, mix well; In the feeding chamber of the internal mixer, seal it, start the screw for mixing, wait for the torque curve fed back by the mixed solution to be stable (the process is about 5min), stop mixing; then quickly transfer the mixed melt to a place that has been preheated to 200°C tableting mold, and put the whole into a tablet press that has been preheated to 220°C for tablet molding. During the tablet pressing process, first run the upper mold of the tablet press to the position where it contacts the upper surface of the forming mold and pause for 2 minutes, keep warm, pressurize again until it is completely closed, and keep the pressure for 5 minutes; Perform rapid cooling, soak and wash in a mixture of ethanol and water at 80°C for 30 minutes, take it out and dry it in the air; finally place the film in the f...

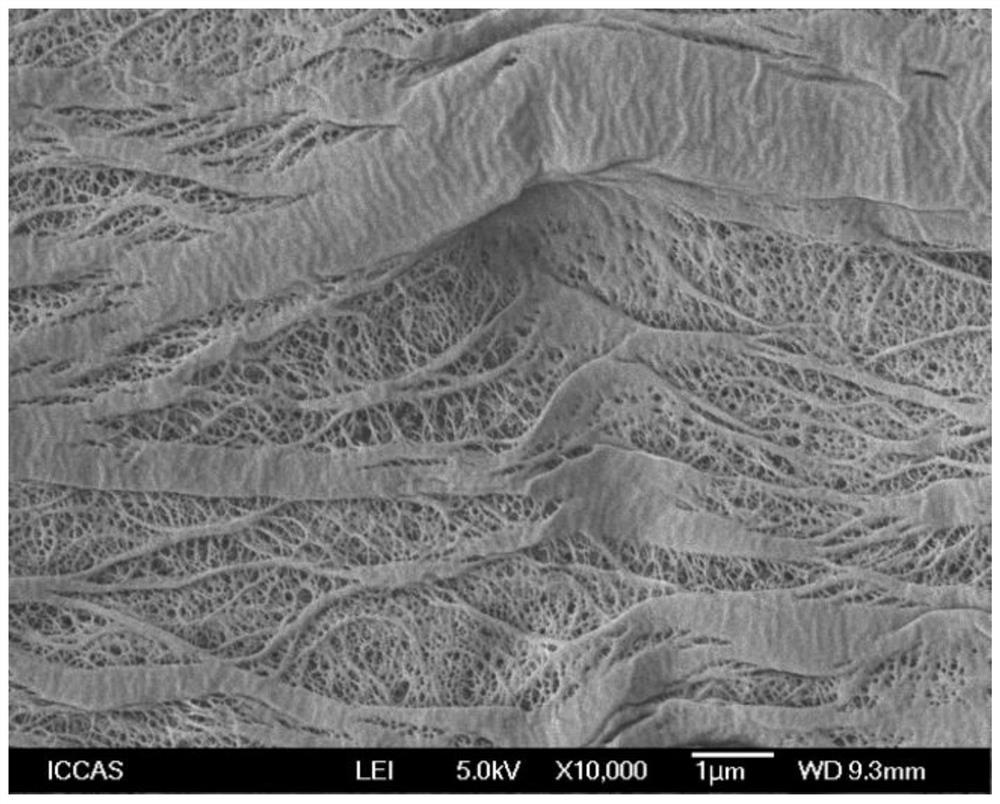

Embodiment 2

[0046] Add 7.5 grams of polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer F127 to 42.5 grams of high-density polyethylene (HDPE) powder, mix well; In the feeding chamber of the internal mixer, seal it, start the screw for mixing, wait for the torque curve fed back from the mixed melt to be stable, and stop mixing; then quickly transfer the mixed melt to the tableting mold that has been preheated to 200°C , and put the whole into a tablet press that has been preheated to 220°C for tablet molding. During the tablet pressing process, first run the upper mold of the tablet press to the position where it contacts the upper surface of the forming mold and pause for 2 minutes, keep warm, pressurize again until it is completely closed, and keep the pressure for 5 minutes; Perform rapid cooling, soak and wash in a mixture of ethanol and water at 80°C for 30 minutes, take it out and dry it in the air; finally place the film in the fastening clip of the biaxial...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com