Polyimide polymer containing selenium and preparation method and application thereof

A technology of selenium polyimide and polyimide, which is applied in the field of selenium-containing polyimide polymer materials and its preparation, can solve the problem of increased refractive index of polyimide materials, low Abbe number, limited applications, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] The preparation of selenium-containing polyimide polymer film comprises the following steps:

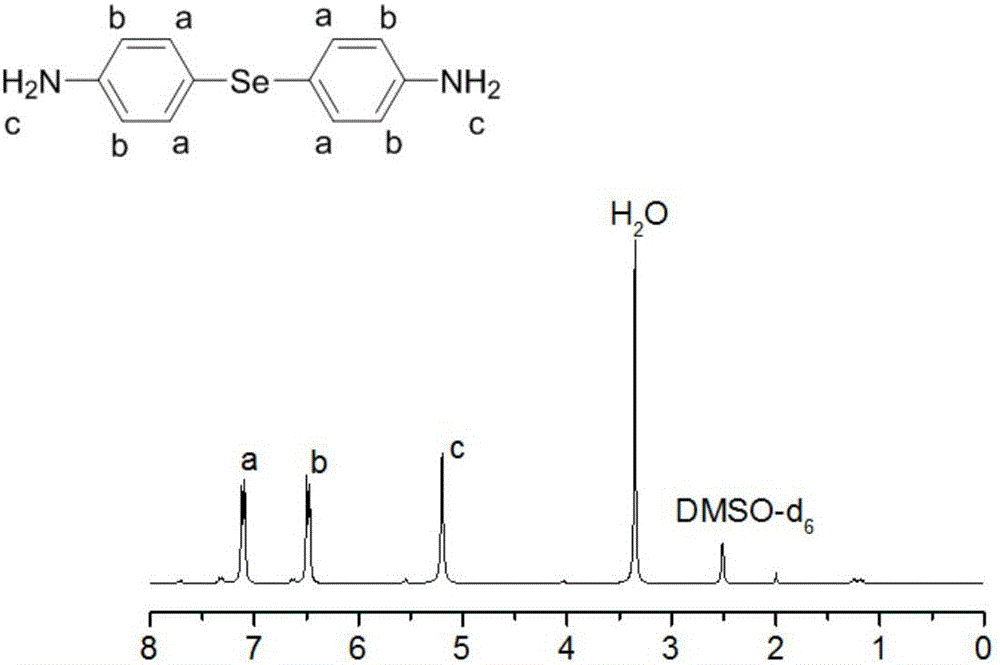

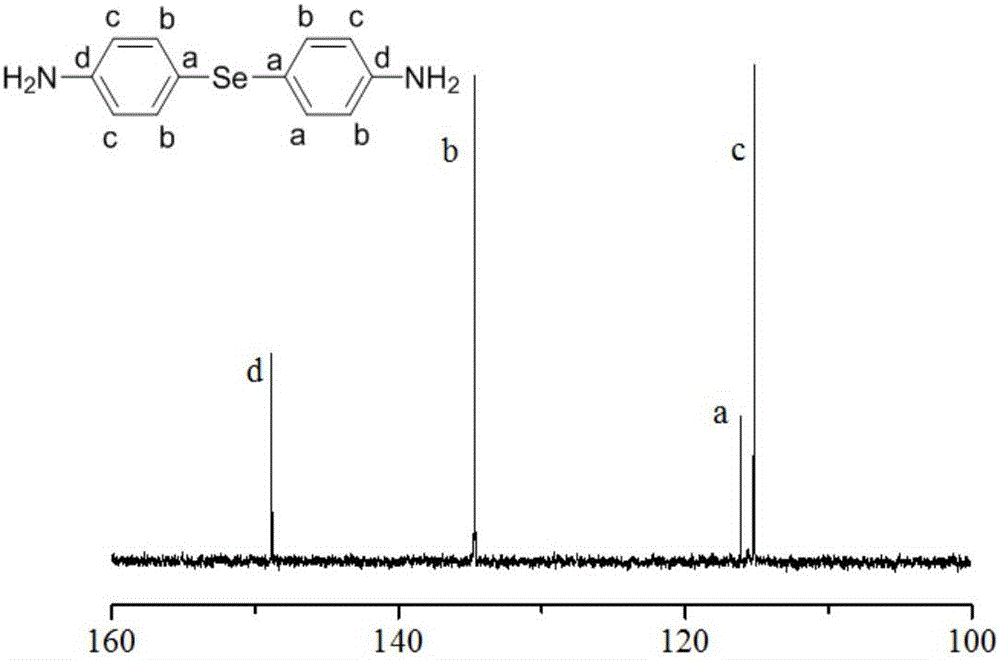

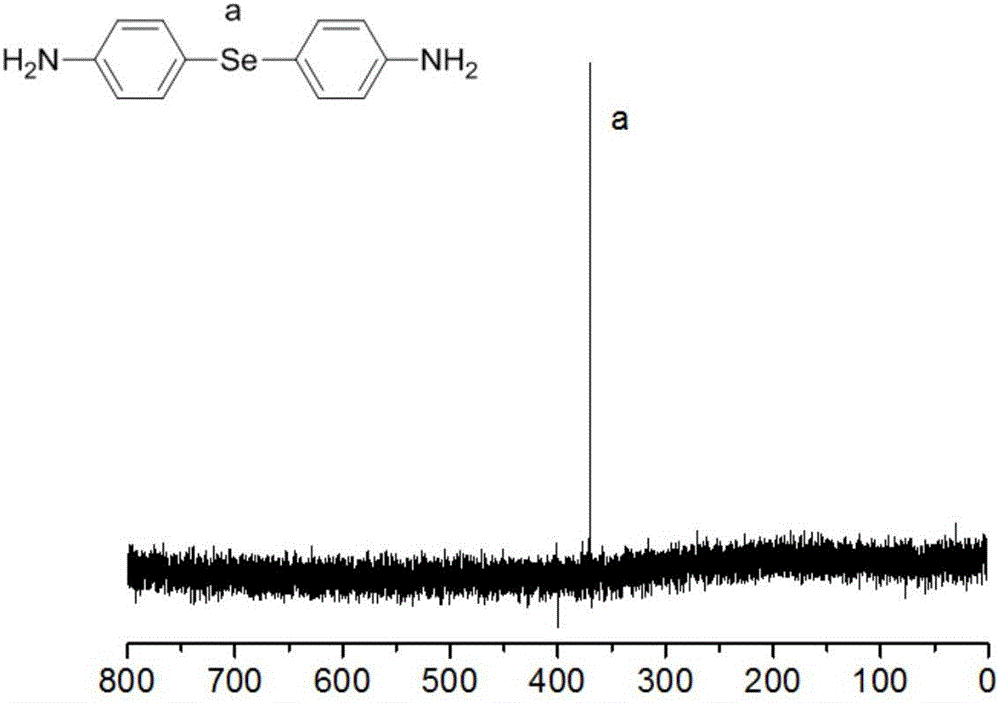

[0061] (1) Synthesis of selenoether diamine monomer 4,4'-diaminodiphenylselenide (BASP): first pass argon gas into a 50mL three-necked flask for two hours to remove the air, and then p-iodoaniline (10mmol), CuI (1mmol), K 2 CO 3 (10mmol), DMSO (20mL) were added in the three-necked flask, stirred to dissolve p-iodoaniline, then dry selenium powder (6mmol) was added to the reaction system, and the reaction temperature was preset to be 120°C; the reaction device was protected from light, and The argon gas was always passed through, and the reaction process was tracked by TLC. After about 12 hours, the reaction of p-iodoaniline could be basically completed. After cooling naturally, filter with suction in the dark, wash with water and extract with ethyl acetate (40mL×3), dry the organic phase with anhydrous sodium sulfate, filter with suction again, and separate by silica gel col...

Embodiment 2

[0069] The steps of this embodiment are basically the same as in Example 1, and the difference is that the dianhydride monomer is 4,4'-oxydiphthalic anhydride (ODPA) in the step (2) to obtain selenium-containing polyamic acid PAA2; In (3), the selenium-containing polyamic acid PAA2 is thermally imidized to obtain the selenium-containing polyimide film PI2 (BASP / ODPA). attached Figure 6 For the infrared spectrogram of the selenium-containing polyamic acid PAA2 that this step obtains, from Figure 6 It can be seen in: at 3450cm -1 There is an obvious and broad absorption peak, which is attributed to the hydroxyl (-OH) absorption in the carboxyl (-COOH) contained in PAA; at 1660cm -1 , 1532cm-1 , 1260cm -1 The three absorptions are attributed to the characteristic absorption of the amide structure (-CONH-); Figure 7 The infrared spectrogram of the selenium-containing polyimide thin film PI2(BASP / ODPA) that this step obtains, from Figure 7 It can be seen in: in the origina...

Embodiment 3

[0072] The preparation of selenium-free polyimide polymer film comprises the following steps:

[0073] (1) Preparation of polyamic acid: Weigh 4,4'-diaminodiphenyl ether (ODA) (0.2640g, 1mmol) and dissolve it in 3mL of anhydrous DMF, stir under argon atmosphere until ODA is completely dissolved, continue Argon was passed for half an hour, then the dianhydride monomer pyromellitic anhydride (PMDA) (0.2189g, 1mmol) was added, the reaction temperature was maintained at 30°C, and polyamic acid PAA3 was obtained after stirring for 3 hours, and the feeding ratio was controlled so that it The solid content is 15%.

[0074] (2) Preparation of polyimide (PI) film: quickly smear polyamic acid PAA3 on a glass plate for thermal imidization, and go through the following heating program: heating at 70°C for 1h, heating at 100°C for 1h, heating at 150°C for 1h , heated at 200°C for 1.5h, at 250°C for 1.5h, and at 300°C for 0.5h. After cooling down to room temperature naturally, the glass pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid containing ratio | aaaaa | aaaaa |

| solid containing ratio | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com