High-permeability concrete sealed waterproofing agent and preparation method thereof

A concrete and high-permeability technology, which is applied in the field of concrete waterproof materials, can solve the problems of poor sealing effect of micro-cracks inside concrete, insignificant improvement of concrete waterproof and impermeability performance, and increased process complexity, etc., to achieve enhanced impervious and waterproof effects , low cost and low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

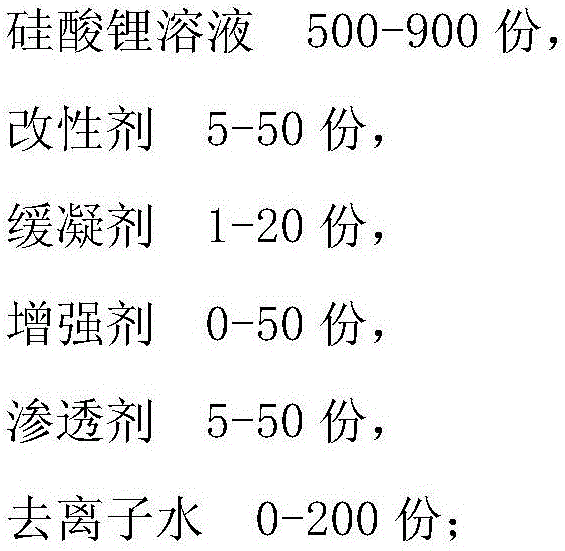

[0033] The high-permeable concrete sealing and waterproofing agent of the present embodiment, the parts by weight of each component are: 600 parts of commercially available lithium silicate solution, 20 parts of lithium hydroxide, 5 parts of zinc stearate, 5 parts of triethanolamine, polyether 5 parts of modified polydimethylsiloxane, 100 parts of inert nano-silica aqueous dispersion, and 100 parts of deionized water.

Embodiment 2

[0035] The high-permeable concrete sealing and waterproofing agent of the present embodiment, the parts by weight of each component are: 600 parts of commercially available lithium silicate solution, 10 parts of lithium hydroxide, 5 parts of sodium gluconate, 5 parts of lithium carbonate, fluorine 10 parts of propane amido fluorocarbon surfactant, 100 parts of inert nano zirconium dioxide aqueous dispersion, 100 parts of deionized water.

Embodiment 3

[0037] The high-permeable concrete sealing and waterproofing agent of this embodiment, the parts by weight of each component are: 600 parts of commercially available lithium silicate solution, 10 parts of potassium oxide, 5 parts of sodium lignosulfonate, phosphate-based fluorocarbon surface active 5 parts of agent, 5 parts of polyether-modified polydimethylsiloxane, 200 parts of inert nano-alumina sol, and 100 parts of deionized water.

[0038] Above-mentioned embodiment adopts following preparation method:

[0039] 1) Weigh the lithium silicate solution and the modifier in the reaction kettle in proportion, stir and mix evenly to obtain the modified lithium silicate solution;

[0040] 2) Weigh the enhancer, retarder, penetrant, deionized water, and inert nano-sol in proportion, and add them to the modified lithium silicate solution obtained above in sequence, keep stirring during the addition process, and finally obtain a high-osmosis type Concrete sealant waterproofing age...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com