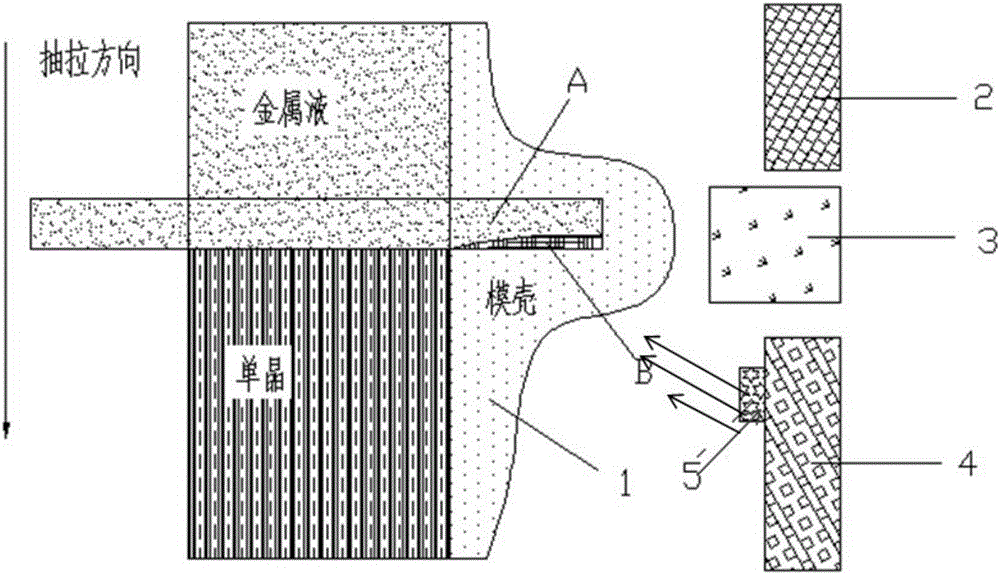

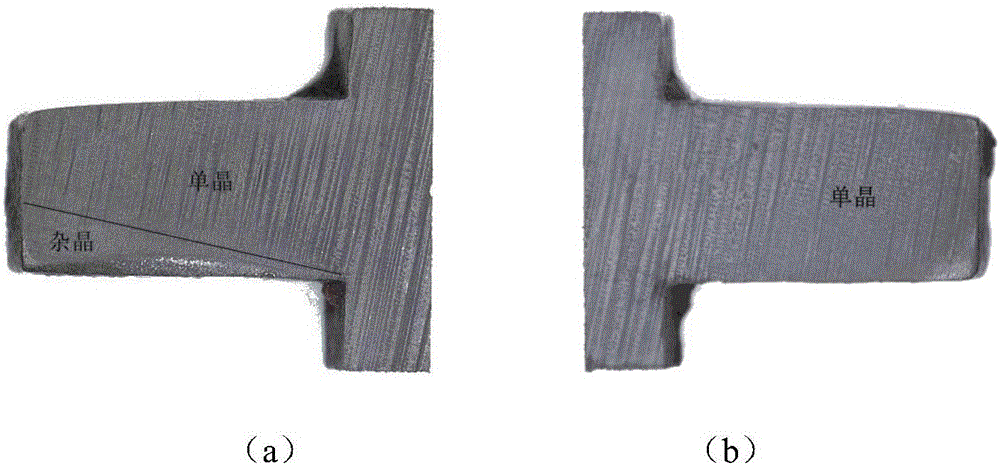

Method for preventing mixed crystal defect of single crystal blade based on laser heating technology

A single crystal blade, laser heating technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problem of low bond strength, difficult to achieve ceramic fiber and mold fit, mold shell The strength is difficult to be guaranteed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is further described in detail with the given examples below, so as to completely and accurately understand the characteristics of the present invention.

[0026] The following is a specific embodiment given by the inventor.

[0027] The present invention is a method for preventing miscellaneous crystal defects in single crystal blades based on laser heating technology, comprising the following steps: (1) preparing slurry: the ratio of silica sol to corundum powder is 1:3, wherein the corundum powder is 200 mesh and 320 mesh Mix corundum powder, the mixing ratio is 1:2; the speed of the mixing bucket is set to 60rad / min, weigh 30kg of silica sol and add it to the mixing bucket, after stirring for 30min, add 90kg of corundum powder into the mixing bucket 10 times , the interval between each addition is 2 hours, and tools are used to break up the resulting massive precipitates during each addition to ensure that the slurry does not settle.

[0028] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com