Method for manufacturing solar cell electrode

A technology for solar cells and electrodes, applied in the field of solar cells, can solve the problems of low conductivity of nickel, high cost of silver powder, increase in cost, etc., and achieve the effects of overcoming easy oxidation, improving production efficiency, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

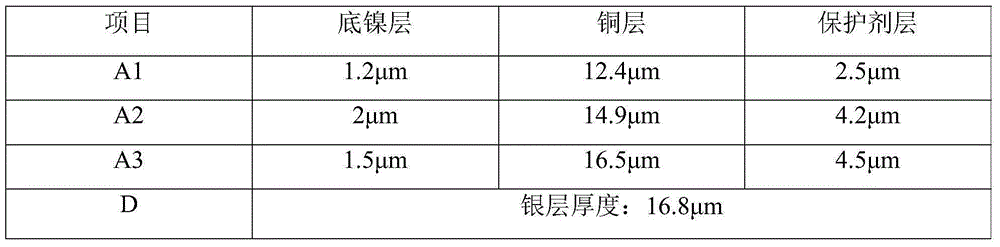

Embodiment 1

[0035] This embodiment is used to illustrate the method for manufacturing solar cell electrodes provided by the present invention.

[0036] Concentration is that the stannous octoate aqueous solution of 2% by weight is spray-coated to the solar cell silicon wafer (the specification is: 156cm 2 ×156cm 2 , with a thickness of 180 μm, the same below), and then baked in an oven at 80° C. for 30 minutes. Then cover the mask on the surface of the solar cell silicon wafer, the mask includes a light-transmitting area and an opaque area and the pattern of the light-transmitting area is an electrode pattern, and then UV exposure is carried out, and the exposure energy is 2000mj / cm 2 , wherein, since the pattern of the light-transmitting region of the mask is an electrode pattern, the UV-exposed part is an electrode pattern. Afterwards, the mask is removed, and the solar cell silicon wafer treated by UV exposure is treated with a temperature of 15° C. to develop a liquid solution (the ...

Embodiment 2

[0043] This embodiment is used to illustrate the method for manufacturing solar cell electrodes provided by the present invention.

[0044] An aqueous solution of titanium acetylacetonate with a concentration of 8% by weight was sprayed onto the surface of the solar cell silicon wafer, and then baked in an oven at 140° C. for 10 minutes. Then cover the mask on the surface of the solar cell silicon wafer, the mask includes a light-transmitting area and an opaque area and the pattern of the light-transmitting area is an electrode pattern, and then UV exposure is carried out, and the exposure energy is 1500mj / cm 2 , wherein, since the pattern of the light-transmitting region of the mask is an electrode pattern, the UV-exposed part is an electrode pattern. After that, the mask is removed, and the solar cell silicon wafer treated by UV exposure is soaked for 60 seconds in a developing solution (the developing solution is a mixture of ethanol and methanol in a weight ratio of 1:1) a...

Embodiment 3

[0051] This embodiment is used to illustrate the method for manufacturing solar cell electrodes provided by the present invention.

[0052] The concentration is 15% by weight of aluminum (trihydroxybutanone) 3 The aqueous solution is sprayed onto the surface of the silicon wafer of the solar cell, and then baked in an oven at 80° C. for 30 minutes. Then cover the mask on the surface of the solar cell silicon wafer, the mask includes a light-transmitting area and an opaque area and the pattern of the light-transmitting area is an electrode pattern, and then UV exposure is carried out, and the exposure energy is 700mj / cm 2 , wherein, since the pattern of the light-transmitting region of the mask is an electrode pattern, the UV-exposed part is an electrode pattern. Afterwards, the mask is removed, and the solar cell silicon wafer treated by UV exposure is soaked in 60° C. developing solution (the developing solution is a tetramethylammonium hydroxide aqueous solution with a conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com