A plate heat exchanger with an insert support

A plate heat exchanger and plate heat exchange technology, applied in indirect heat exchangers, heat exchanger types, heat exchanger shells, etc., can solve the problems of high gas flow resistance, large welding range, and weak ability to withstand pressure differences , to achieve the effect of improving sealing reliability, convenient cleaning and maintenance, and large sealing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] 1. Structure:

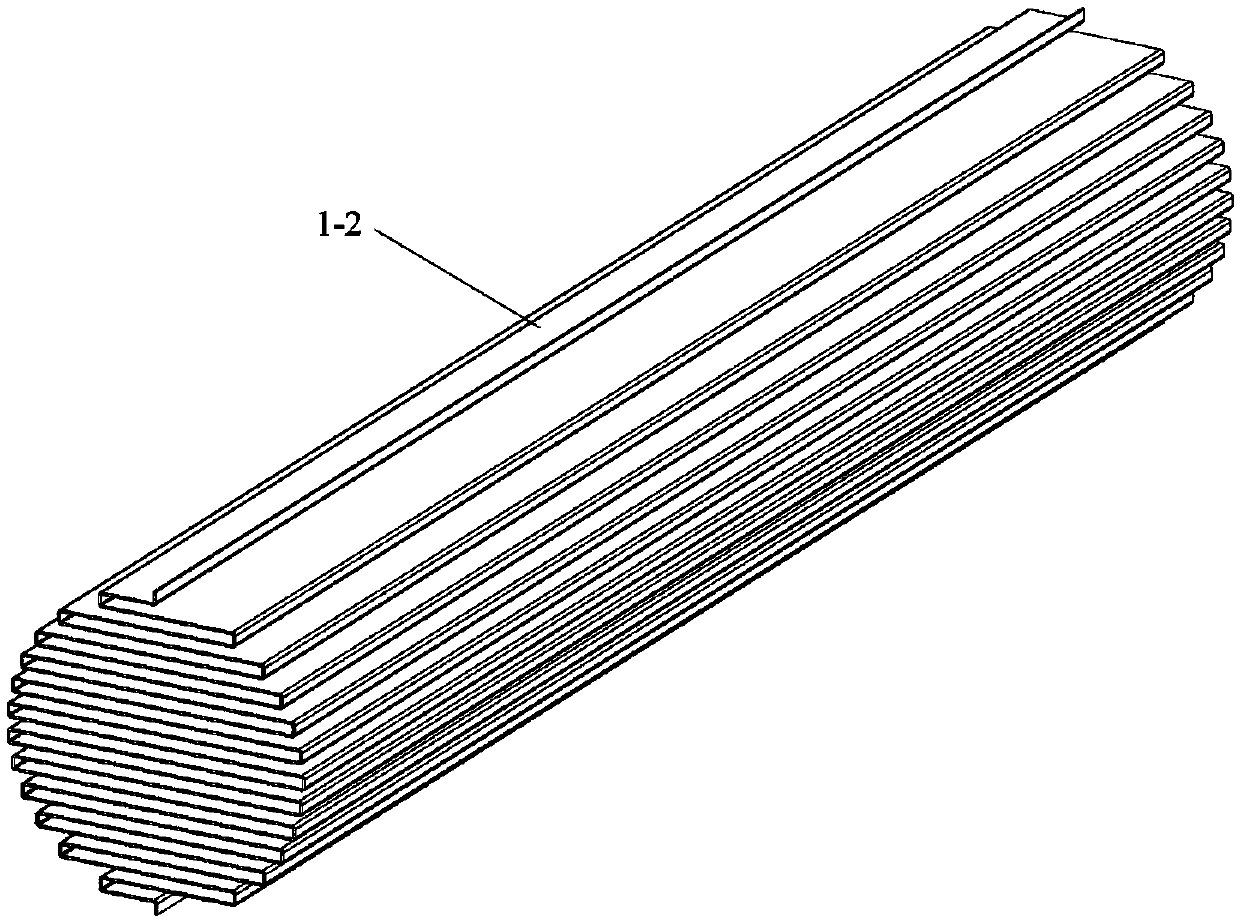

[0081] Such as Figure 7 , 23 As shown, a plate heat exchanger includes a B plate heat exchange unit 1-2, a continuous twisted strip plate 3-1, a double semicircular shell 4-3, a head 6, and an integrated isolation grid without a sealing ring 9- 2 and side interface 7. The continuous twisted belt plate 3-1 is arranged between the plates of the B plate heat exchange unit 1-2, and the double semicircular shell 4-3 is wrapped in the B plate through the connection of the shell straight edge 11-1 and the sealing edge 11-2. Outside the plate heat exchange unit 1-2, the head 6 is arranged at both ends of the double semicircular shell 4-3 through the connection of the head flange 10-2 and the shell flange 10-1, an integral type without a sealing ring The isolation grid 9-2 is set between the head 6 and the double semicircle shell 4-3, the side interface 7 is connected to the side opening of the double semicircle shell 4-3, and can be connected with other pipe...

Embodiment 2

[0113] According to the relevant drawings, a plate heat exchanger includes A plate heat exchange unit 1-1, discontinuous twisted belt plate 3-2, rectangular flat shell 4-2, head 6, separated strip isolation grid 9-1 and the side interface 7 . Such as Figure 22 As shown, the seal head 6 is arranged at both ends of the rectangular flat shell 4-2, the side interface 7 is set on the wall of the rectangular flat shell 4-2 and is adjacent to the seal head 6, and the rectangular flat shell 4-2 is provided with bolts Hole 8. in:

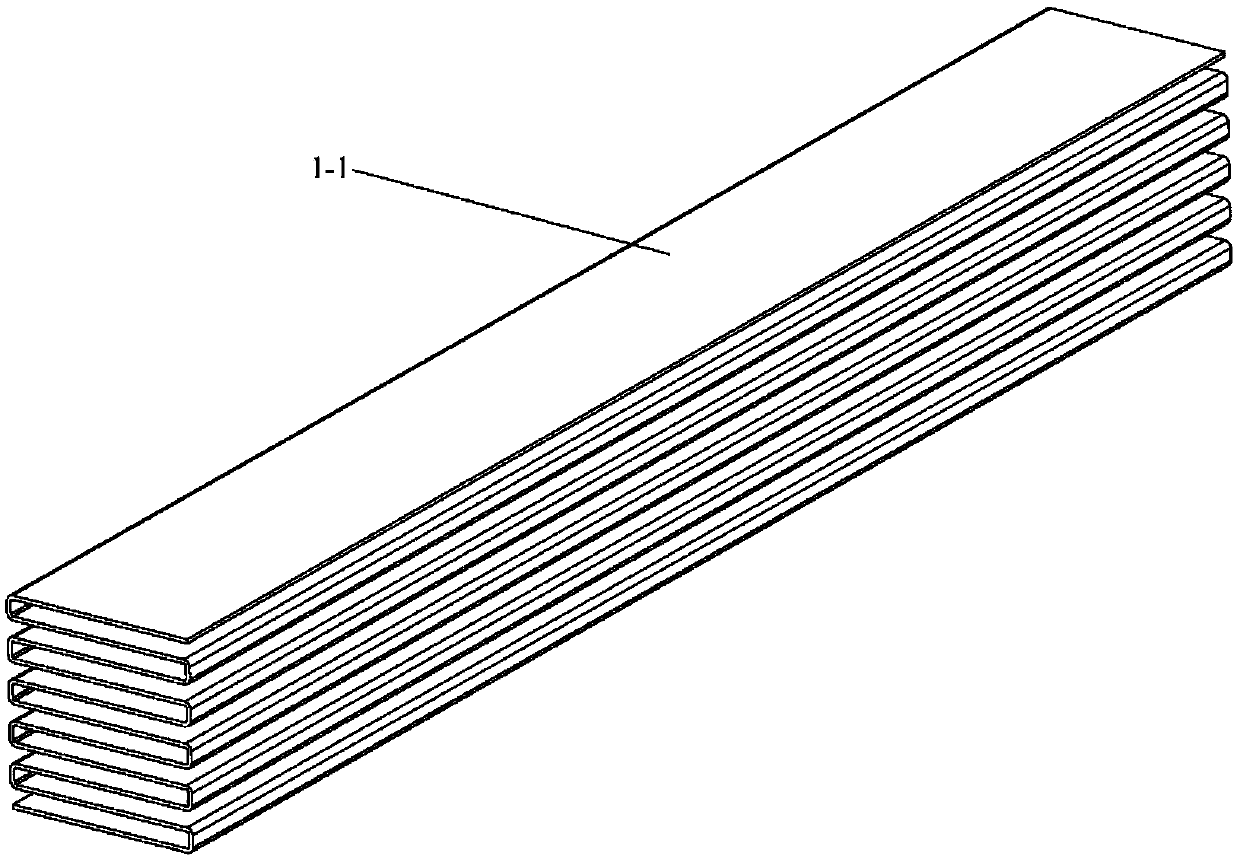

[0114] (1) Plate heat exchange unit: such as figure 1 As shown, the A plate heat exchange unit 1-1 is a plate heat exchange unit with a rectangular cross-section formed by reciprocating folding of a whole metal flat plate.

[0115] (2) Supports between boards: such as Figure 5 , 8 , 9, the support between the plates is a discontinuous twisted belt plate 3-2: it is made of helical twisted belts 2-1 that are parallel to each other and have a certain di...

Embodiment 3

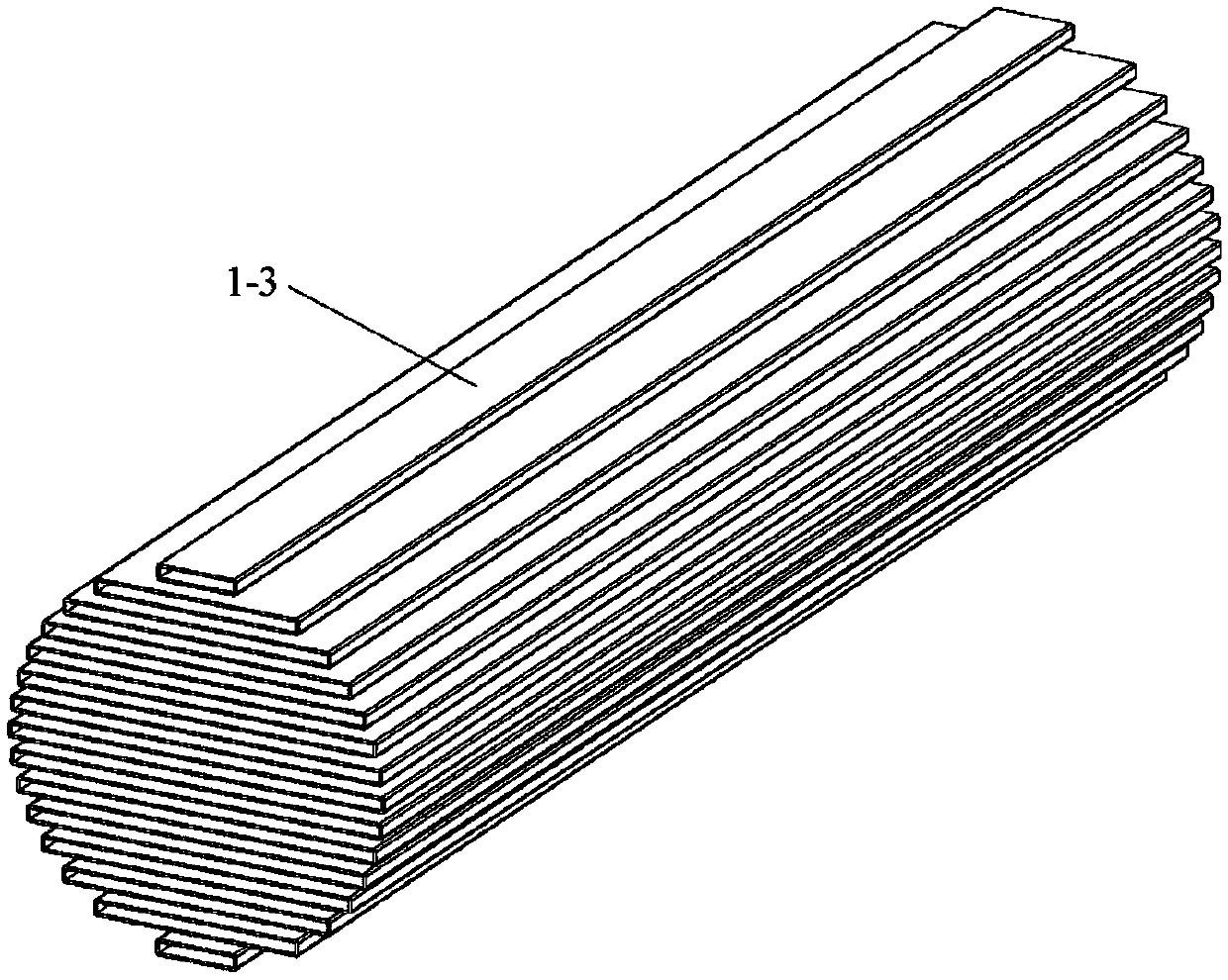

[0122] According to the relevant drawings, a plate heat exchanger includes a plate heat exchange unit 1-1, a diamond-shaped twisted belt plate 3-3, an integrated shell 4-1, a head 6, and a separate strip isolation grid 9-1 and side interface 7, wherein:

[0123] (1) Supports between boards: such as Figure 10 , 11 As shown in 12, the support between the plates is a diamond-shaped twisted belt plate 3-3: it is formed by connecting the spiral twisted belts 2-1 arranged crosswise and having a certain angle between the axial direction and the fluid flow direction with the groove 2-2. Its characteristic is that its supporting strength and turbulence effect are weaker than those of the discontinuously twisted belt plate 3-2, but the flow resistance is smaller.

[0124] (2) Shell: Since the difference between the pressure in the flow channel and the ambient pressure is below 10kPa, an integrated shell 4-1 can be used, such as Figure 18 , 19 As shown, the metal plate forming A pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com