Preparation method of nitride film

A nitride and thin film technology, which is applied in the field of nitride thin film preparation, can solve the problems of material surface quality degradation, affecting device performance, etc., and achieve the effect of improving flatness, enhancing migration ability, and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) Select a c-plane self-supporting gallium nitride substrate, use acetone, ethanol and deionized water to sonicate for 5 minutes, and finally use high-purity nitrogen to blow off its moisture;

[0033] 2) Transfer the cleaned gallium nitride substrate into the MOCVD system, with the front side - (0001) facing up, the pressure of the reaction chamber is 100torr, and the reaction chamber is NH 3 / H 2 Mixed atmosphere (the ratio of ammonia in the mixed gas is 5%), the temperature of the reaction chamber is raised to 1050°C, and the heat treatment time is 300s;

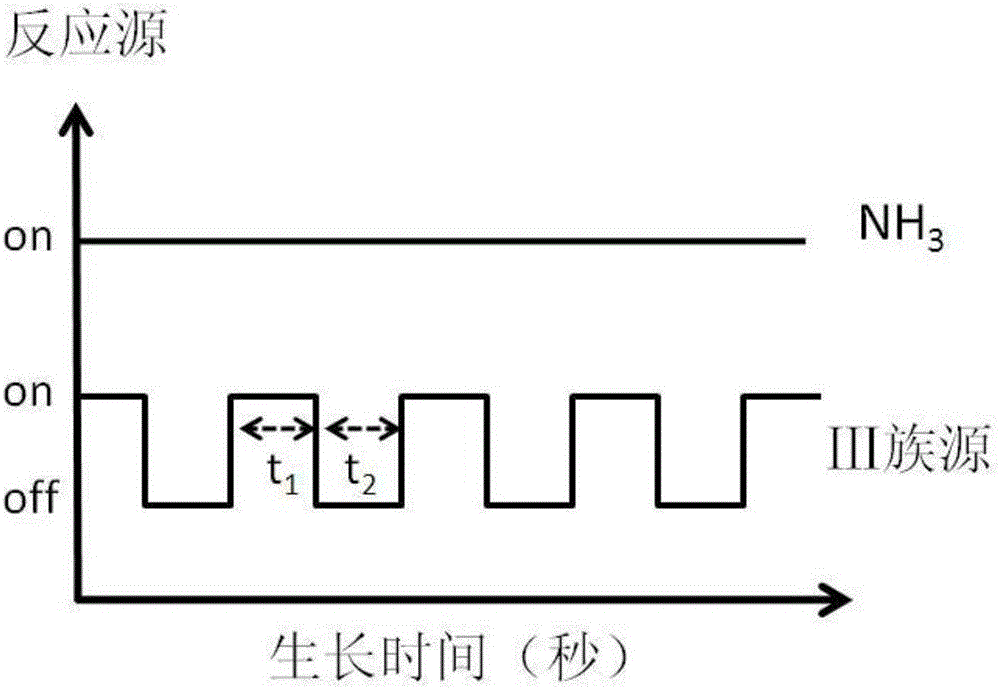

[0034] 3) Keeping the pressure and temperature constant, feed the Group V source (ammonia) and Group III source (trimethylgallium) at the same time, with the V / III ratio of 3000, in H 2 Grow for 1 second under carrier gas conditions;

[0035] 4) Keep the pressure, temperature, and ammonia constant, stop feeding the reaction source trimethylgallium, and the process lasts for 1 second;

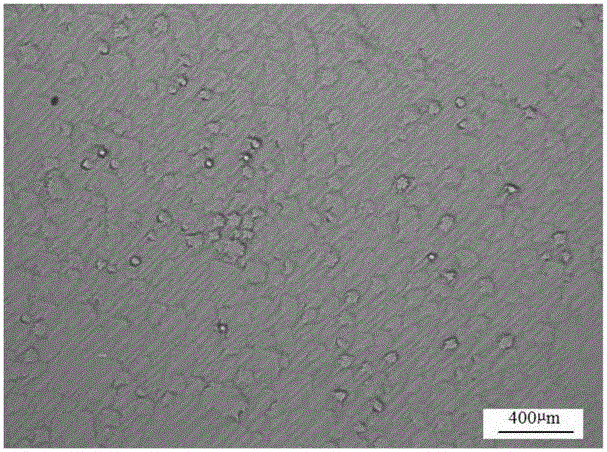

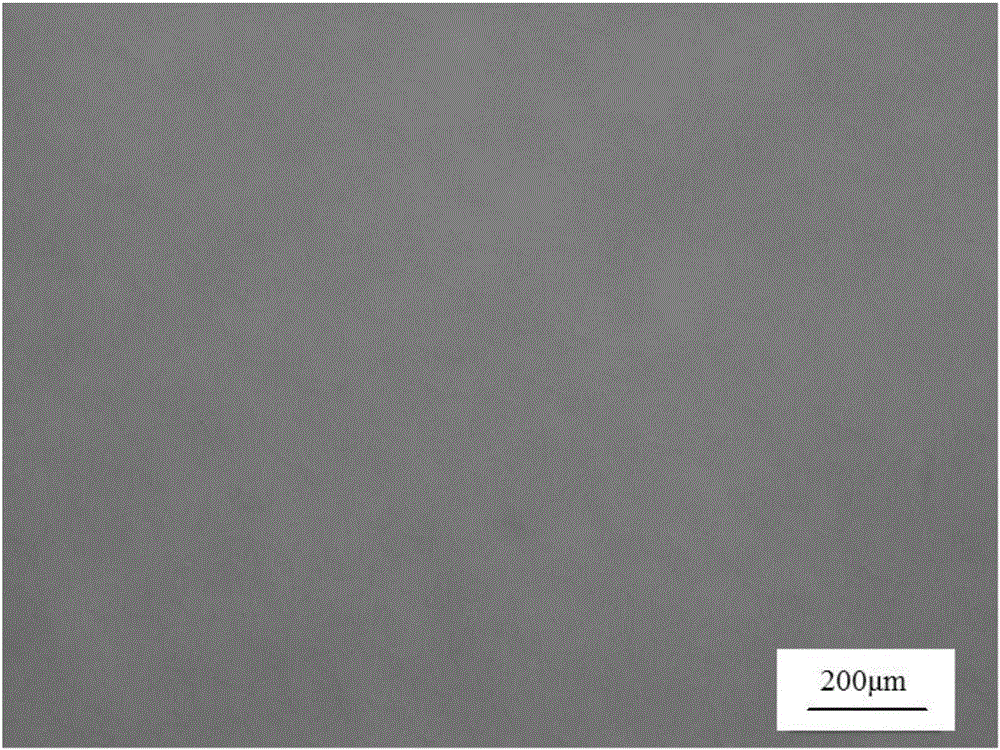

[0036] 5) Steps 3) and 4)...

Embodiment 2

[0039] 1) Select a self-supporting gallium nitride substrate on the a side, use acetone, ethanol and deionized water to sonicate for 5 minutes, and finally use high-purity nitrogen to blow off its moisture;

[0040] 2) Transfer the cleaned gallium nitride substrate into the MOCVD system, face a upwards, the pressure of the reaction chamber is 500torr, and the reaction chamber is NH 3 / H 2 Mixed atmosphere (the ratio of ammonia gas in the mixed gas is 10%), the temperature of the reaction chamber is raised to 850°C, and the heat treatment time is 600s;

[0041] 3) Keeping the pressure and temperature constant, feed the V-group source (ammonia) and III-group source (diethylgallium, trimethylindium) at the same time, with the V / III ratio of 5000, in the hydrogen-nitrogen mixed gas (1 : 1) grow for 10 seconds under the condition of carrier gas;

[0042] 4) Keep the pressure, temperature, and ammonia constant, and stop feeding the Group III sources of diethylgallium and trimethylin...

Embodiment 3

[0046] 1) Select an m-plane self-supporting gallium nitride substrate, use acetone, ethanol and deionized water to sonicate for 5 minutes, and finally use high-purity nitrogen to blow off its moisture;

[0047] 2) Transfer the cleaned gallium nitride substrate into the MOCVD system, with the m side up, the pressure of the reaction chamber is 50torr, and the reaction chamber is NH 3 / H 2 Mixed atmosphere (the ratio of ammonia in the mixed gas is 30%), the temperature of the reaction chamber is raised to 1100 ° C, and the heat treatment time is 30;

[0048] 3) Keeping the pressure and temperature constant, feed the group V source (ammonia) and group III source (trimethylgallium, trimethylaluminum) at the same time, with the V / III ratio of 1000, and grow under the condition of hydrogen carrier gas 30 seconds;

[0049] 4) Keep the pressure, temperature, and ammonia constant, stop feeding the reaction sources trimethylgallium and trimethylaluminum, and the duration of this proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com