Pre-paved type polyolefin self-adhering film waterproof sheet and preparation method thereof

A waterproof sheet and self-adhesive film technology, which is applied in the direction of adhesives, film/sheet adhesives, etc., can solve the problems of poor softness of polymer waterproof sheets, self-adhesive surface wettability and initial tackiness, etc. , to achieve the effects of excellent peel strength, good waterproof performance and good construction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

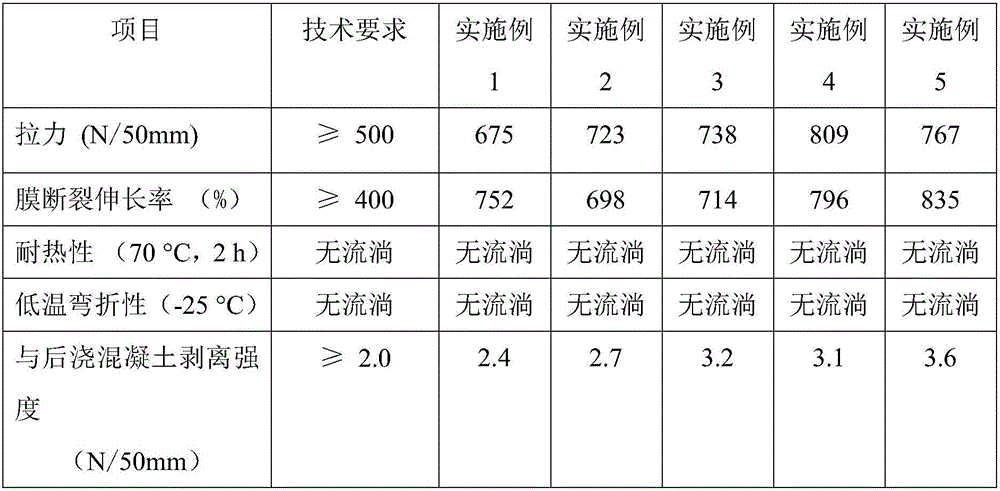

Embodiment 1

[0037] Take 60 parts of HDPE, 30 parts of LDPE, 10 parts of styrene-isoprene-styrene block copolymer, and use it as a benchmark for the mass fraction of other materials, 3 parts of C5 hydrogenated petroleum resin, 0.3 parts of rutile titanium dioxide 0.2 parts of antioxidant B215, mixed on a high-speed mixer for 15 minutes, put the above-mentioned uniformly mixed materials into a single-screw extruder, set the temperature of the single-screw extruder to 200 ° C, and the materials passed through the T-die of the extruder Head, cooling roll, traction roll, winding roll to obtain pre-laid polyolefin self-adhesive film waterproof sheet. The physical performance test of the obtained pre-laid polyolefin self-adhesive film waterproof sheet is carried out according to GB / T 23457-2009.

Embodiment 2

[0039] Take 50 parts of HDPE, 30 parts of LDPE, 10 parts of styrene-isoprene-styrene block copolymer, 10 parts of polyethylene graft material, and use it as a benchmark for the mass fraction of other materials, C5 hydrogenated petroleum resin 3 parts, 0.3 parts of rutile titanium dioxide, 0.2 parts of antioxidant B215, mixed on a high-speed mixer for 15 minutes, put the above-mentioned homogeneously mixed materials into a single-screw extruder, set the temperature of the single-screw extruder to 200 ° C, The material passes through the T-die head of the extruder, the cooling roll, the traction roll, and the winding roll to obtain a pre-laid polyolefin self-adhesive film waterproof sheet. The physical properties of the pre-laid polyolefin self-adhesive film waterproof sheet were tested according to GB / T23457-2009.

Embodiment 3

[0041]Take 50 parts of HDPE, 30 parts of LDPE, 10 parts of styrene-isoprene-styrene block copolymer, 10 parts of polyethylene graft material, and use it as a benchmark for the mass fraction of other materials, C5 hydrogenated petroleum resin 6 parts, 0.3 parts of rutile titanium dioxide, 0.2 parts of antioxidant B215, mixed on a high-speed mixer for 15 minutes, put the above-mentioned homogeneously mixed materials into a single-screw extruder, set the temperature of the single-screw extruder to 200 °C, The material passes through the T-die head of the extruder, the cooling roll, the traction roll, and the winding roll to obtain a pre-laid polyolefin self-adhesive film waterproof sheet. The physical properties of the pre-laid polyolefin self-adhesive film waterproof sheet were tested according to GB / T23457-2009.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com