Multifunctional nanometer film and preparation method thereof

A nano-membrane, multi-functional technology, applied in the field of preparation of the aforementioned multi-functional nano-membrane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

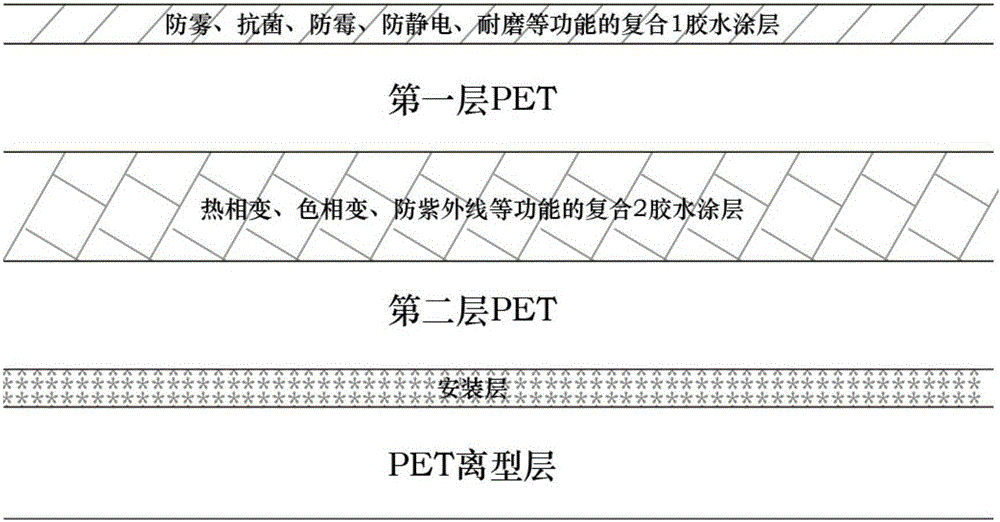

Image

Examples

Embodiment 1

[0028] 1. Preparation of the first composite nano-slurry

[0029] ① Triclosan powder: 3 parts. ②Titanium dioxide (TIO2) powder: 5 parts. ③ Conductive zinc oxide (ZnO) powder: 8 parts. ④ Butanone: 80 parts. ⑤ Dispersant, BYK-204: 1 part. Put ①②③④⑤ into the planetary rapid disperser in turn, then add zirconium baht with a diameter of 0.3mm twice the total weight of the powder, set the speed at 6000 rpm / 1h, and obtain the first composite nano-slurry after intermittent dispersion for 5 hours.

[0030] 2. Prepare the first composite functional coating:

[0031] ①UV curable resin: 60 parts, ②The first composite nano-slurry: 40 parts, mix ①② for 40 minutes and filter with 1um pressure filter, then put it into the feeding tank, adopt VO coating and UV curing method Complete the first composite glue coating on the surface of the first layer of PET base film with a thickness of 23um. The dry film thickness is 3um, and the UV laser energy is 400mj.

[0032] 3. Preparation of vanad...

Embodiment 2

[0041] The formula for preparing the first composite glue and the process for forming the first composite coating and the second composite coating are exactly the same as in Example 1.

[0042] The formula of the second composite glue proposed in Preparation Example 2 is as follows: according to parts by weight, ① vanadium dioxide nano-slurry: 0.4 parts. ② Photosensitive color-changing paste: 0.3 parts, ③ UV absorber: 3 parts, ④ Acrylic glue: 40 parts, ⑤ Thinner: 40 parts.

[0043] Measured according to the usual method, at an ambient temperature of 20 degrees, the infrared blocking rate is 18%, the ultraviolet blocking rate is 99%, the visible light transmittance is 63%, the Escherichia coli sterilization rate is 99.99%, the anti-fog contact angle is 20 degrees, and the surface resistance is 10.8 Power ohm cm, surface hardness 4H wear-resistant, when the ambient temperature is 50 degrees, the infrared blocking rate is 72%, the ultraviolet blocking rate is 99%, the visible lig...

Embodiment 3

[0046] The formula for preparing the first composite glue and the process for forming the first composite coating and the second composite coating are exactly the same as in Example 1.

[0047] The formula of the second composite glue proposed in Preparation Example 2 is as follows: according to parts by weight, ① vanadium dioxide nano-slurry: 0.5 parts. ② Photochromic paste: 0.4 parts, ③ UV absorber: 3 parts, ④ Acrylic glue: 40 parts, ⑤ Thinner: 40 parts.

[0048] Measured according to the usual method, at an ambient temperature of 20 degrees, the infrared blocking rate is 16%, the ultraviolet blocking rate is 99%, the visible light transmittance is 61%, the Escherichia coli sterilization rate is 99.99%, the anti-fog contact angle is 20 degrees, and the surface resistance is 10% of 8 Power ohm cm, surface hardness 4H wear-resistant, when the ambient temperature is 50 degrees, the infrared blocking rate is 74%, the ultraviolet blocking rate is 99%, the visible light transmitta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com