Artificial compound soil layer percolation system for removing polybrominated diphenyl ether

A polybrominated diphenyl ether and artificial compounding technology, which is applied in the field of environmental engineering, can solve problems such as limited application, and achieve the effects of wide application range, good effluent quality, and simple system maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

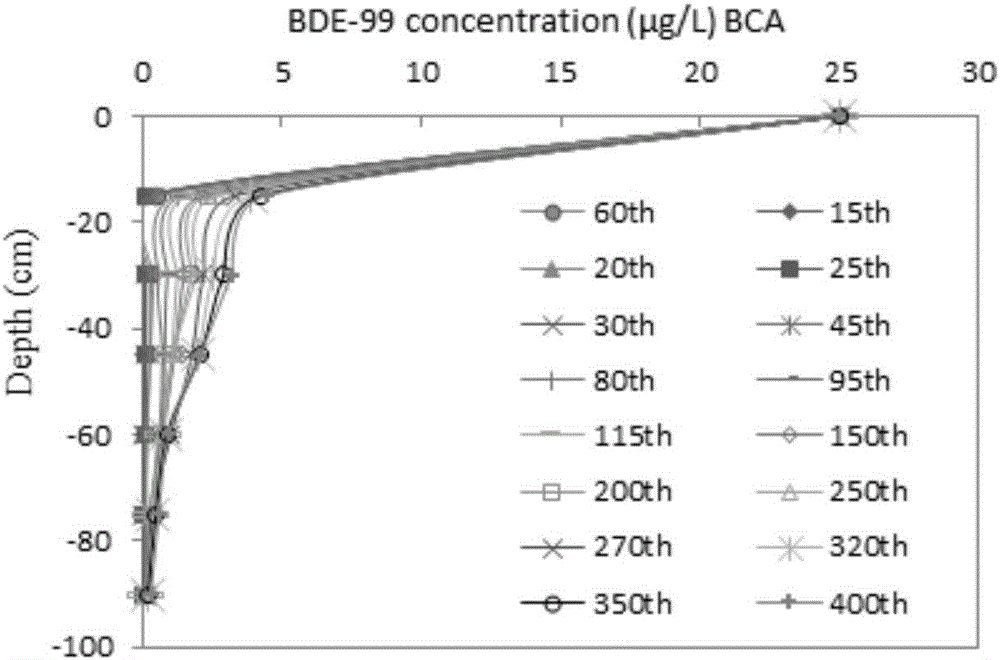

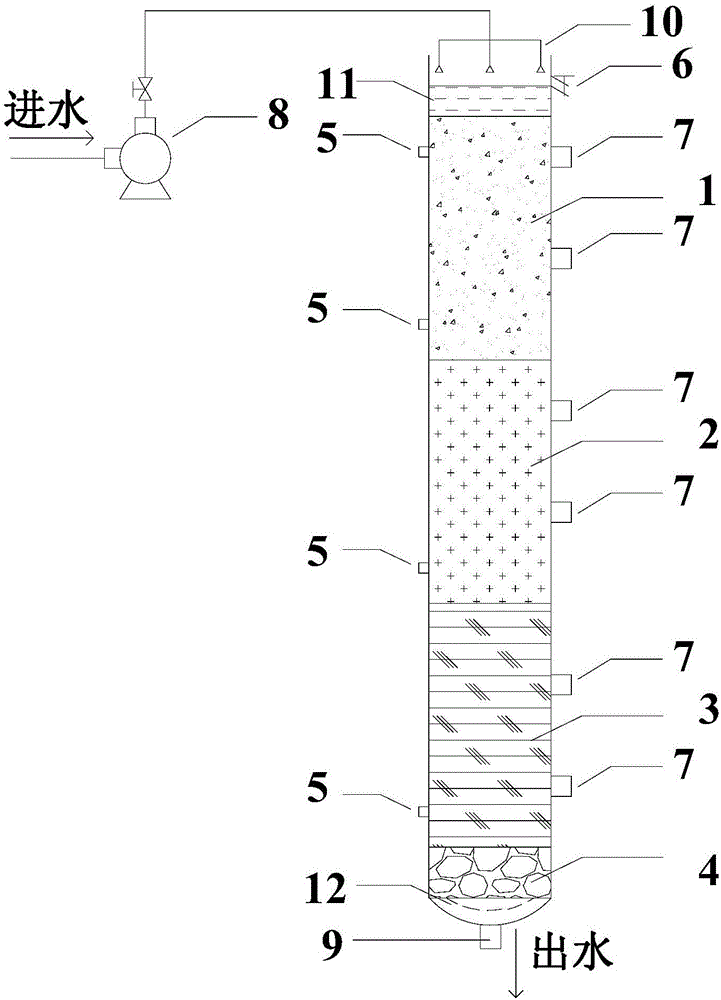

Method used

Image

Examples

preparation example Construction

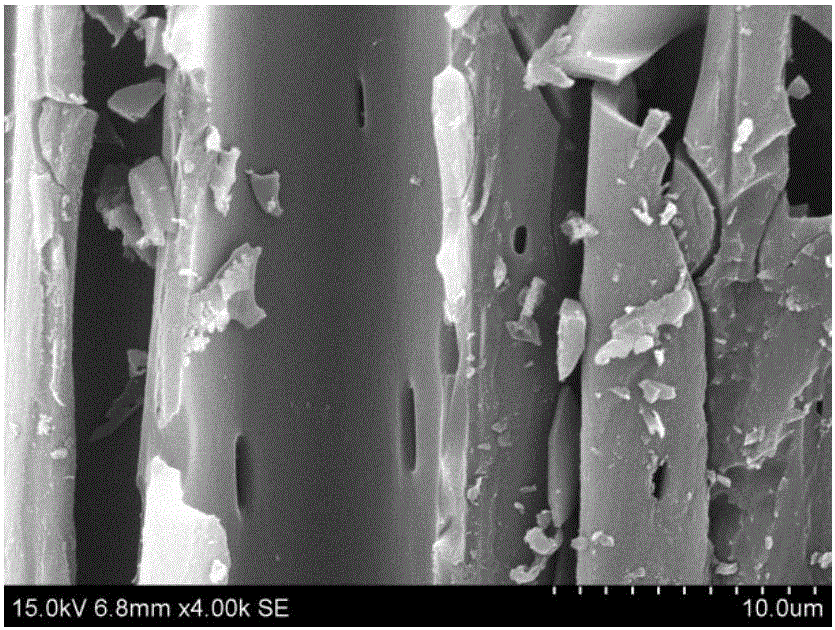

[0036] The preparation of the adsorption and aerobic degradation layer 2 particle medium, after mixing the materials evenly, adding clean water accounting for 5-8% of the total weight of the mixture, stirring evenly, aging at 2-6°C for 12-16 hours, using The mechanical mold is extruded once, dried naturally for 4-6 hours, dried at 80-120°C for 10-12 hours, then roasted in a muffle furnace at 400-500°C for 3-5 hours under the condition of feeding nitrogen, and cooled with the furnace Form after reaching room temperature.

[0037] The preparation procedure of the biochar is as follows: firstly, the agricultural waste straw is crushed into small pieces of 1 to 3 cm, heated in an oxygen-limited rotary muffle furnace catalyzed by sulfonated coal at 160 to 200 ° C for 2 to 4 hours, and naturally cooled to Prepared at room temperature.

[0038] The bottom of the supporting layer 4 is provided with a perforated water collection pipe, and a non-woven interlayer with a pore diameter of...

Embodiment 1

[0043] An artificial composite soil infiltration system for strengthening the removal of polybrominated diphenyl ethers, which intercepts aerobic degradation layer 1 composed of fine sand and river surface sediments in the river bed of Chaobai River with a mass ratio of 5:10:60:1:10:0.5 , Natural farmland soil in Daxing District, biochar, and Chaobai River reclaimed water recharge area are rich in Proteobacteria and Acidobacteria. The composite medium is composed of soil and zero-valent iron powder. The specific surface area after mixing is 12.838m 2 / g, the filling thickness is 30cm.

[0044] Adsorption and aerobic degradation layer 2 is a filter prepared by medium-temperature heat treatment of materials such as fly ash, alkali-extracted black carbon, biomass, zeolite powder, diatomite or sepiolite powder with a mass ratio of 70:1:3:2:25. Adsorption granular medium, the medium has an organic matter content of 5.7g / kg and a specific surface area of 20.6m 2 / g, particle comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com