Catalyst, preparation method and application, regeneration method of working fluid for hydrogen peroxide production by anthraquinone method, and method for producing hydrogen peroxide

A catalyst and application technology, applied in the direction of peroxide/peroxyhydrate/peroxyacid/superoxide/ozonide, quinone oxide preparation, chemical instruments and methods, etc., can solve the problem of low regeneration efficiency of circulating working fluid problems, to achieve the effect of improving recycling efficiency, prolonging the replacement cycle, and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

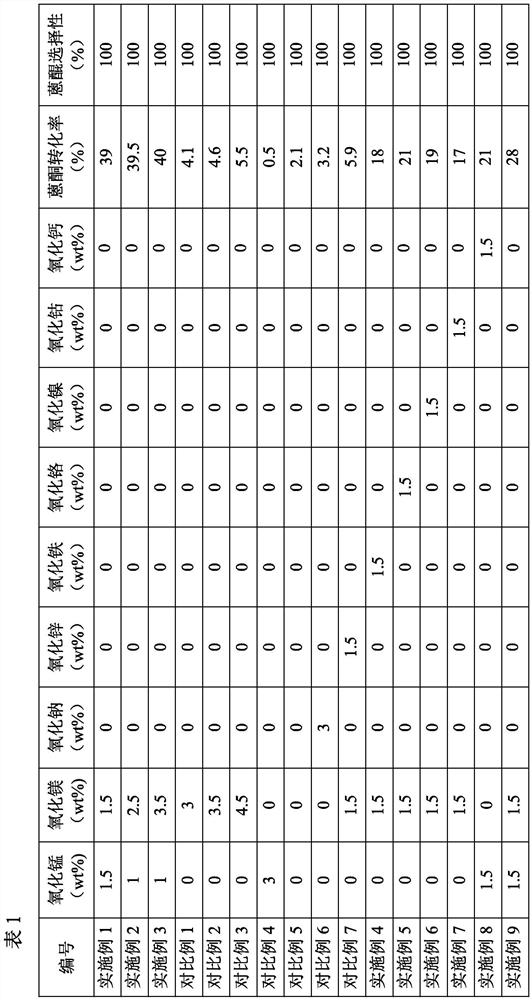

Embodiment 1

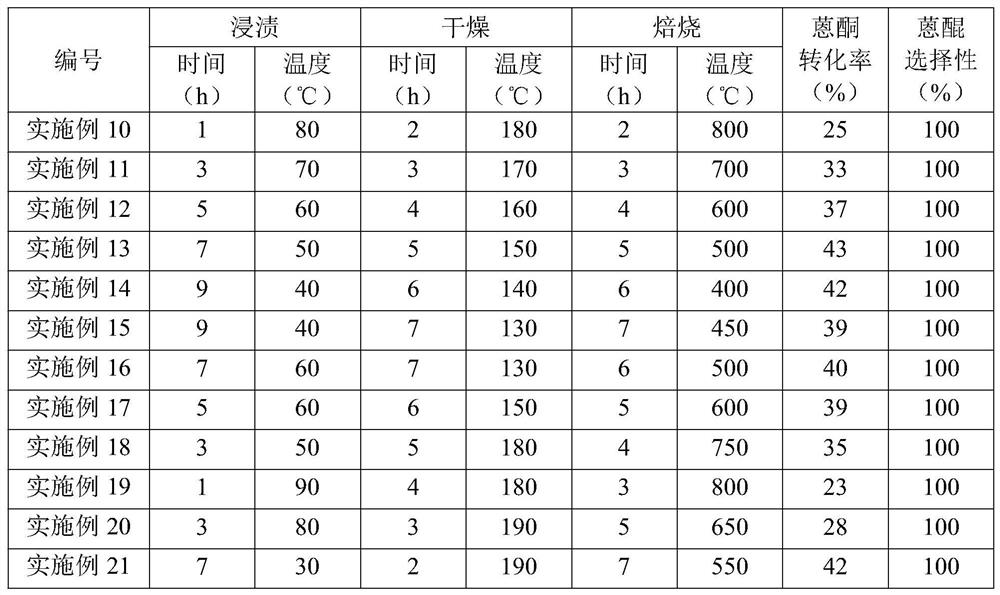

[0082] (1) Mn(NO 3 ) 2 and Mg(NO 3 ) 2 Dissolve in water to prepare 50mL impregnation solution. In the immersion solution, Mn(NO 3 ) 2 The content is 2g, Mg(NO 3 ) 2 The content is 2.8g. 50g of alumina (purchased from Bailingwei, product number 13-0750) was added to the above impregnation solution, and saturated with stirring at a temperature of 60°C for 8h. Then, the impregnated mixture was dried under normal pressure at 130° C. for 4 hours, followed by calcination at 600° C. for 4 hours, thereby obtaining the catalyst according to the present invention (the composition is listed in Table 1).

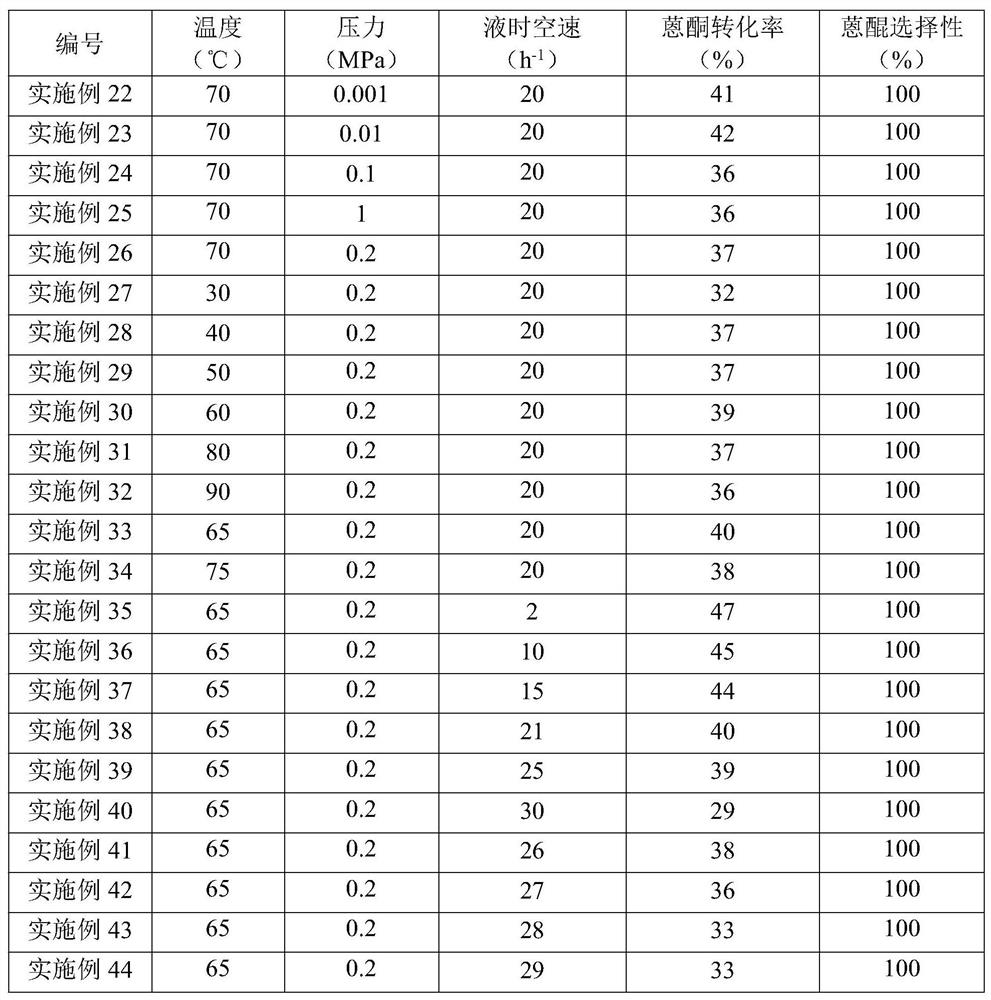

[0083] (2) Pack 10 g of the catalyst prepared in step (1) in a miniature fixed-bed reactor to form a catalyst bed. The working liquid is sent from the bottom into the miniature fixed-bed reactor, and reacts with the catalyst under the air atmosphere. Among them, the liquid hourly volumetric space velocity of the working fluid is 20h -1 , the temperature in the catalyst bed w...

Embodiment 2

[0085] Adopt the same method as Example 1 to prepare the catalyst and regenerate the working fluid, the difference is that in step (1), in the impregnation solution, Mn(NO 3 ) 2 The content is 1.4g, Mg(NO 3 ) 2 The content is 4.7g. The composition of the catalyst is listed in Table 1. The experimental results are listed in Table 1.

Embodiment 3

[0087] Adopt the same method as Example 1 to prepare the catalyst and regenerate the working fluid, the difference is that in step (1), in the impregnation solution, Mn(NO 3 ) 2 The content is 1.4g, Mg(NO 3 ) 2 The content is 6.6g. The composition of the catalyst is listed in Table 1. The experimental results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com