Catalyst for preparing isobutyl alcohol by using synthesis gas and application thereof

A catalyst and a technology for synthesis gas, which are applied in the field of catalysts for preparing isobutanol with high selectivity from synthesis gas and the field of preparation thereof, and can solve the problems of low reaction space velocity, low selectivity of propanol and/or isobutanol, and high reaction space velocity. , to achieve the effect of improving alcohol selectivity, enhancing carbon chain growth ability, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

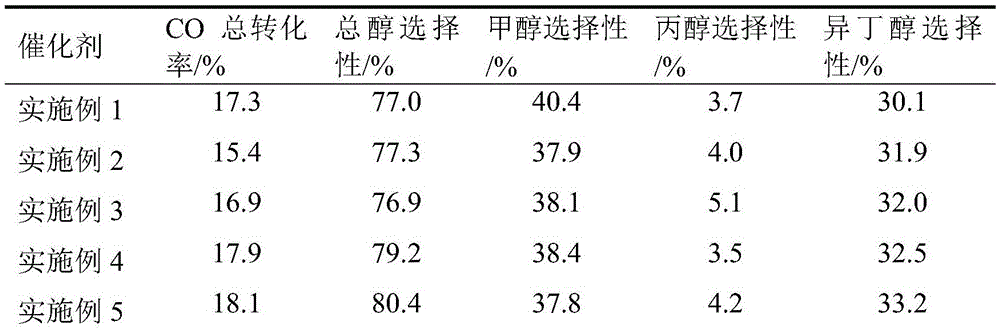

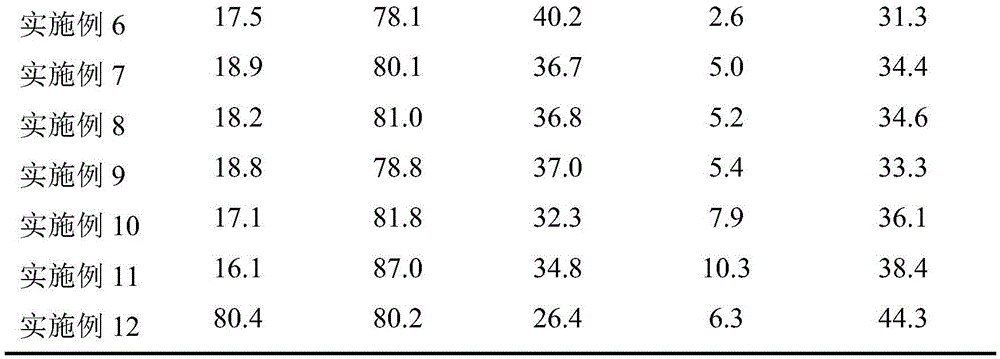

Examples

Embodiment 1

[0029] Zn 0.75 Na 0.06 Cr 0.25 o x Catalyst is prepared as follows:

[0030] Weigh 0.75mol of zinc nitrate and 0.25mol of chromium nitrate, dissolve them in 1000mL of distilled water, then dissolve 3mol of NaOH in 1000mL of water, co-precipitate the two aqueous solutions, age at 80°C for 3h, and filter at 100 It was dried overnight at ℃ and calcined at 400℃ for 12h. After the calcination is completed, the catalyst intermediate supports 0.03mol of Na 2 CO 3 , dried overnight at 80°C and calcined at 400°C for 2h to obtain Zn 0.75 Na 0.06 Cr 0.25 o x catalyst.

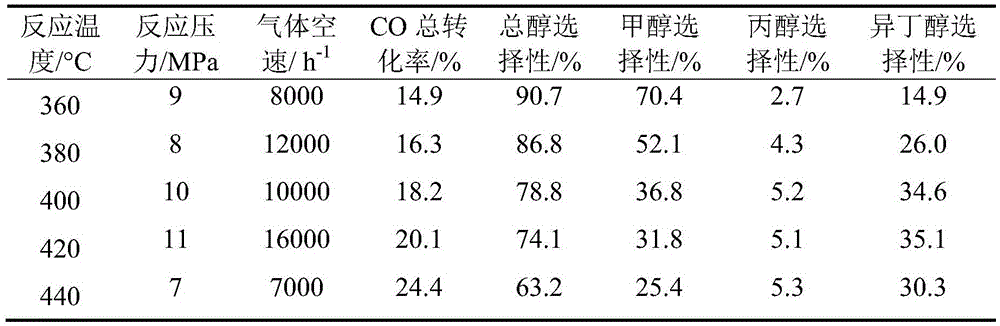

[0031] 1 g of prepared Zn 0.75 Na 0.06 Cr 0.25 o x The catalyst was loaded into a quartz reaction tube with a diameter of 5 mm, and the synthesis gas (n 氢气 :n 一氧化碳 =50:50) into the reaction tube, into the catalytic bed reaction, the reaction temperature is 400 ° C, the reaction system pressure is 10MPa, the gas volume space velocity is 10,000h -1 Syngas to isobutanol reaction under conditions. The reacti...

Embodiment 2

[0033] Zn 0.3 Na 0.01 Cr 0.6 La 0.3 o x Catalyst is prepared as follows:

[0034]Weigh 0.3 mol of zinc nitrate, 0.6 mol of chromium nitrate, 0.3 mol of lanthanum nitrate, and 0.001 mol of magnesium nitrate, and dissolve them in 1000 mL of distilled water. Then dissolve 3mol NaOH in 1000mL water, co-precipitate the two aqueous solutions, age at 80°C for 3h, filter and dry at 100°C overnight, and roast at 400°C for 12h. After the calcination is completed, the catalyst intermediate supports 0.005mol of Na 2 CO 3 , dried overnight at 80°C and calcined at 400°C for 2h to obtain Zn 0.3 Na 0.01 Cr 0.6 La 0.3 o x catalyst.

[0035] 1 g of prepared Zn 0.3 Na 0.01 Cr 0.6 La 0.3 o x The catalyst was loaded into a quartz reaction tube with a diameter of 5 mm, and the synthesis gas (n 氢气 :n 一氧化碳 =50:50) into the reaction tube, into the catalytic bed reaction, the reaction temperature is 400 ° C, the reaction system pressure is 10MPa, the gas volume space velocity is 10,0...

Embodiment 3

[0037] Zn 0.6 K 0.03 Cr 0.5 Ce 0.1 o x Catalyst is prepared as follows:

[0038] Weigh 0.6mol of zinc nitrate, 0.5mol of chromium nitrate, 0.1mol of cerium nitrate, dissolve in 1000mL of distilled water, then dissolve 3mol of NaOH in 1000mL of water, co-precipitate the two aqueous solutions, and age at 80°C 3h, dried at 100°C overnight after filtration, and calcined at 400°C for 12h. After the calcination is completed, the catalyst intermediate supports 0.015mol of K 2 CO 3 , dried overnight at 80°C and calcined at 400°C for 2h to obtain Zn 0.6 K 0.03 Cr 0.5 Ce 0.1 o x catalyst.

[0039] 1 g of prepared Zn 0.6 K 0.03 Cr 0.5 Ce 0.1 o x The catalyst was loaded into a quartz reaction tube with a diameter of 5 mm, and the synthesis gas (n 氢气 :n 一氧化碳 =50:50) into the reaction tube, into the catalytic bed reaction, the reaction temperature is 400 ° C, the reaction system pressure is 10MPa, the gas volume space velocity is 10,000h -1 Syngas to isobutanol reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com