Fire resistant container

A container, fire-resistant technology, applied in the direction of packaging, transportation and packaging, coating, etc., can solve the problem of low fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] The woven quartz glass fabric was coated by dip coating with an aqueous dispersion of vermiculite (Micafield, supplied by Dupré Minerals) having a solids content of about 10% to 17%. Excess vermiculite suspension was removed by squeezing the coated fabric between two rollers before drying the coated fabric with heat. The resulting coated fabric was subjected to an intense flame from an industrial gas torch. The fabric will not ignite even after extensive application of flame.

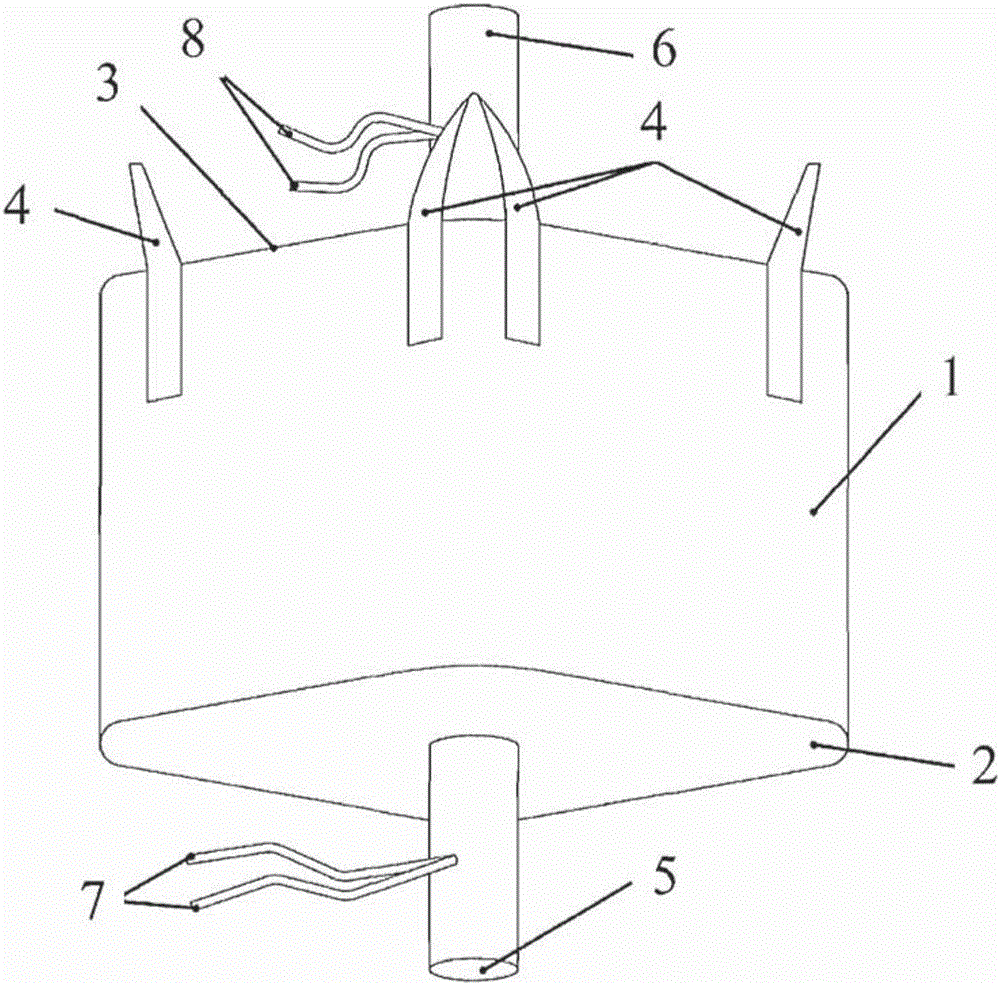

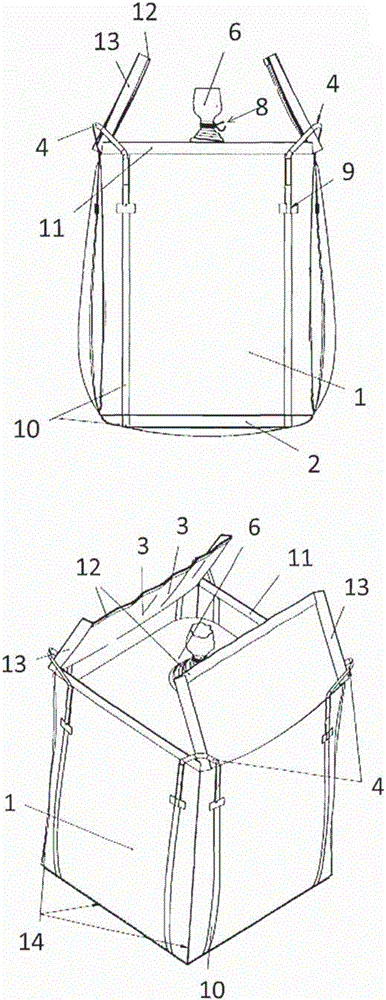

[0067] The nominal width is 90cm, and the impregnated quartz glass material with a nominal service temperature up to 1000°C is formed into a cubic structure FIBC in the form of a nominal 85cm×85cm×100cm cuboid, such as figure 1 The FIBC is shown with fill and discharge nozzles and corner lifting rings and straps all made of impregnated quartz glass fabric. All cut or raw edges of the impregnated quartz glass material are double hemmed or J-stitched. An impregnated quartz glass material of nomi...

Embodiment 2

[0069] Initial testing of open-topped cuboid FIBCs made of the same material as in Example 1 by resistance to heat applied from the outside by a blowtorch and exposure to flames inside the FIBC, the bond wire was determined to be the limiting factor. Different wire types allow the FIBC to maintain integrity for different lengths of time when high internal temperatures are imposed by the burning material within the FIBC.

[0070] Although quartz, ceramic or fiberglass thread has a high operating temperature limit, sutures using such fibers require care and generally slow speeds to avoid breakage of the thread. High temperature polymers including polyimides and aramids (such as Kevlar) with high tensile strength are used where heat resistance is required. It was determined that the preferred thread for making a fire resistant FIBC is a thread formed of a suitable core material (e.g. a polymer with high tensile strength and high temperature performance, such as Kevlar) wherein th...

Embodiment 3

[0072] Three materials for FIBC fabrication were prepared as follows:

[0073] Material 1

[0074] Monolithic quartz glass 600 g / m coated with Micashield DM338S (suspension of chemically exfoliated vermiculite) from Dupres Minerals 2 .

[0075] DM338S is an aqueous dispersion of chemically exfoliated vermiculite with the following properties:

[0076] D90: 160μm~200μm;

[0077] Solid content: 16%~18%

[0078] Viscosity: 3000cps~7000cps

[0079] DM338S includes vermiculite with the following chemical composition:

[0080] SiO 2 : 39.4%; K 2 O: 4.5%; CO 2 : 1.4%; MgO: 25.2%; Fe 2 o 3 : 4.0%; TiO 2 ;0.8%;Al 2 o 3 : 8.8%; CaO: 1.8%; F: 0.5%

[0081] Material 2

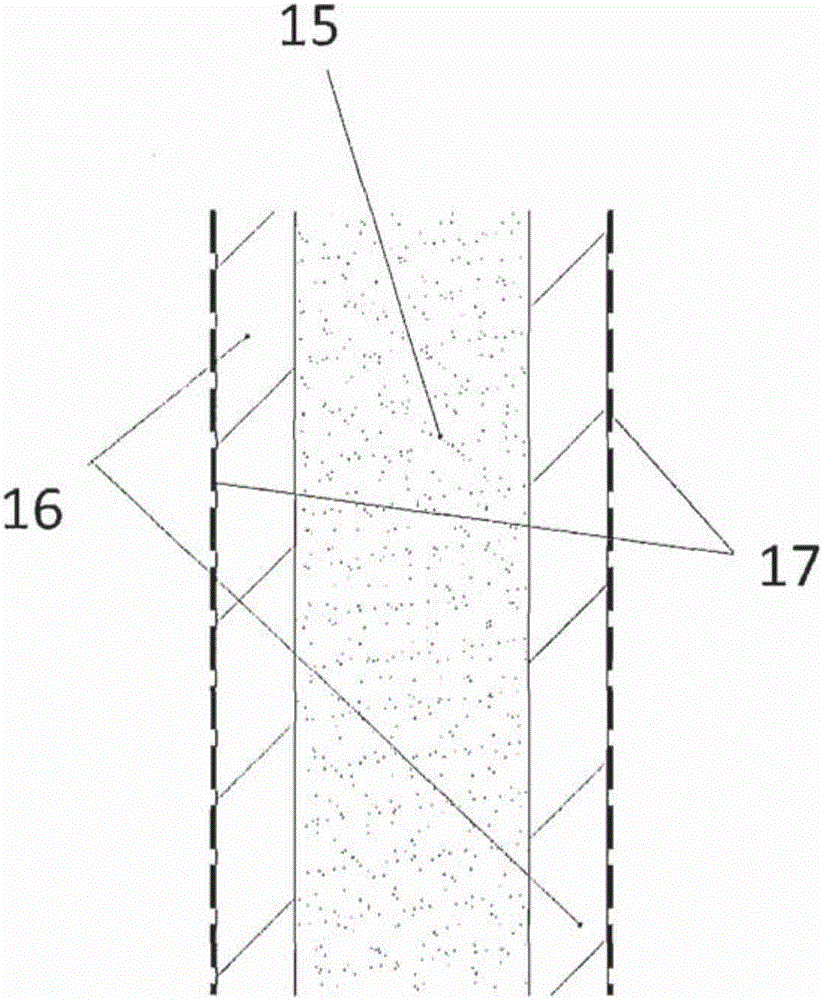

[0082] Consists of two sheets of quartz glass 600g / m coated with Micashield DM338S 2 Interlayer with the middle layer of high quartz needle felt with a thickness of 6mm.

[0083] Material 3

[0084] Consists of two sheets of quartz glass 600g / m coated with Micashield DM338S 2 Interlayer with the middle l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap