High-expansion fireproof low-smoke halogen-free flame retardant composition and thermoplastic resin composition

A thermoplastic resin and high-expansion technology, which is applied in the field of thermoplastic resin composition and high-expansion fire-proof, low-smoke, halogen-free flame retardant composition, can solve the problems of life-threatening, inability to fully meet the hole size, and backward construction technology, etc., to achieve Good processing stability and weather resistance, avoiding degradation and foaming problems, and convenient post-maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

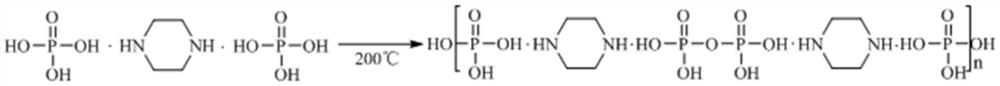

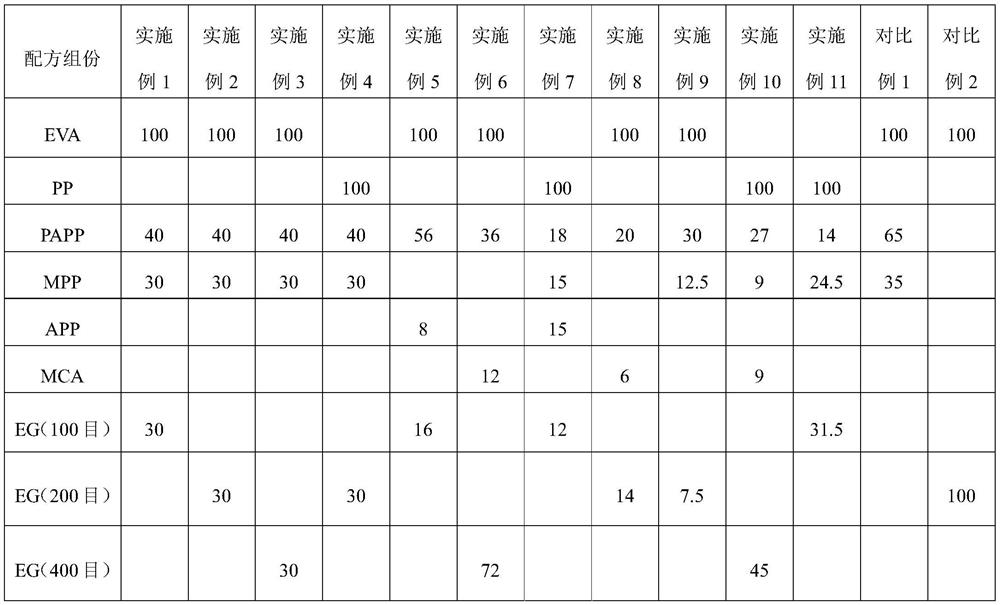

Embodiment 1~11

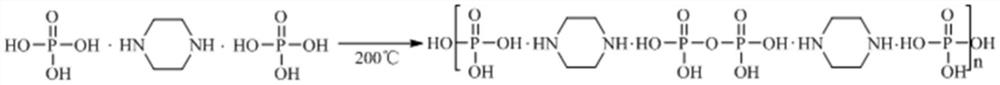

[0099] The piperazine pyrophosphate (PAPP) used is self-made by Shanghai Chemical Research Institute Co., Ltd., and can also be purchased from the market, or use the literature "Plastic Science and Technology" ISSN1005-3360, CN21-1145 / TQ piperazine pyrophosphate to burn polypropylene materials The impact of performance and the method disclosed in the study of its flame retardant mechanism are synthesized. The degree of polymerization of PAPP is 26, the pH is 4.8, and the particle size of the powder is D 50 is 12 μm.

[0100] The ammonium polyphosphate (APP) used is Type II ammonium polyphosphate produced by Zhejiang Xusen Non-Halogen Smoke Suppressant Flame Retardant Co., Ltd., with a degree of polymerization > 1000 and a particle size of D 50 It is 18 μm and the pH is 6.8.

[0101] The melamine pyrophosphate (MPP) used was produced by Sichuan Fine Chemical Research and Design Institute, with a particle size of D 50 8 μm, pH 5.2.

[0102] The melamine cyanuric acid (MCA) us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com