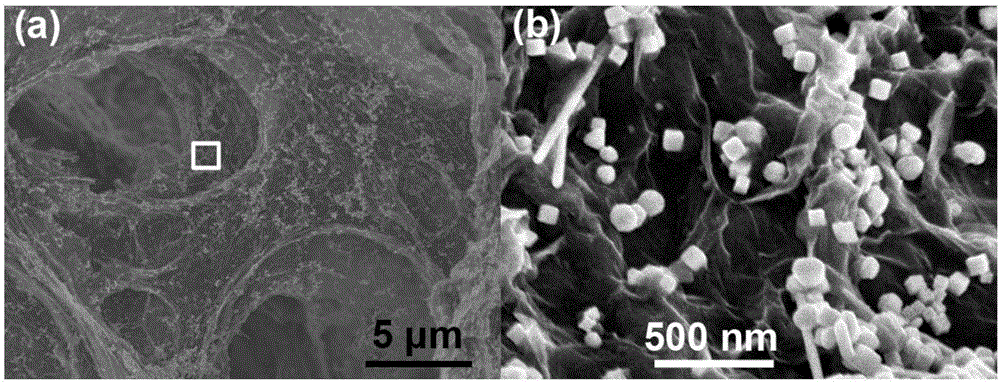

Porous graphite-silver nano-diamond composite as well as preparation method and application thereof

A technology of porous graphene and composite materials, applied in the field of porous graphene-silver nano-square composite materials and its preparation, can solve the problem of limiting the physical enhancement of silver nano-squares, the inability to selectively detect thiram series pesticides, and the inability to obtain selectivity To accurately detect the SERS active substrate and other issues, to achieve the effect of simple preparation method and reduced preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The concrete steps of preparation are:

[0037] Step 1: First, according to the weight ratio of graphene oxide, sodium bisulfite and deionized water as 1:480:135, the three are mixed and ultrasonically oscillated for 5 minutes to obtain a mixed solution. Then the mixed solution was placed at 90° C. for 4 h, and after cooling, a black graphene gel suspended in water was obtained.

[0038] In step 2, the black graphene gel was rinsed once with deionized water and then freeze-dried; wherein, the freeze-drying temperature was -6°C and the time was 30 hours to obtain spongy porous graphene. Then according to the weight ratio of the ethanol dispersion of spongy porous graphene and 0.1wt% silver nano-squares is the ratio of 1:30000, the spongy porous graphene is immersed in the ethanol dispersion of silver nano-squares for 0.5h and then taken out to obtain mid product.

[0039] Step 3, the intermediate product is placed at 30 ℃ and dried first, and then the dried intermediat...

Embodiment 2

[0041] The concrete steps of preparation are:

[0042] Step 1: First, according to the weight ratio of graphene oxide, sodium bisulfite and deionized water as 1:490:130, the three are mixed and then ultrasonically oscillated for 6 minutes to obtain a mixed solution. Then the mixture was placed at 93° C. for 3.5 h, and after cooling, a black graphene gel suspended in water was obtained.

[0043] In step 2, the black graphene gel was rinsed twice with deionized water and then freeze-dried; wherein, the freeze-drying temperature was -9.5° C. and the time was 24 hours to obtain spongy porous graphene. Then according to the weight ratio of the ethanol dispersion of spongy porous graphene and 0.3wt% silver nano-squares is the ratio of 1:23250, after spongy porous graphene is immersed in the ethanol dispersion of silver nano-squares for 0.8h, it is taken out to obtain mid product.

[0044] Step 3, the intermediate product is placed at 35 ℃ and dried first, and then the dried interm...

Embodiment 3

[0046] The concrete steps of preparation are:

[0047] Step 1: First, according to the weight ratio of graphene oxide, sodium bisulfite and deionized water as 1:500:125, the three are mixed and ultrasonically oscillated for 8 minutes to obtain a mixed solution. Then the mixture was placed at 95° C. for 3 h, and after cooling, a black graphene gel suspended in water was obtained.

[0048] Step 2, the black graphene gel was first rinsed with deionized water for 3 times and then freeze-dried; wherein, the freeze-drying temperature was -13°C and the time was 18 hours to obtain spongy porous graphene. Then according to the weight ratio of the ethanol dispersion liquid of spongy porous graphene and 0.6wt% silver nano-squares is the ratio of 1:16500, the spongy porous graphene is immersed in the ethanol dispersion liquid of silver nano-squares for 1h and then taken out to obtain the intermediate product.

[0049] Step 3, the intermediate product is first dried at 40°C, and then the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole diameter | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com