Rapid preparation of large-area graphene/metal composite structure SERS substrate method

A technology of metal composite structure and metal nanostructure, applied in the direction of material excitation analysis, instruments, measuring devices, etc., can solve the problems of high cost, instability, distance increase, etc., and achieve low processing cost, good consistency, and high processing speed fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below by embodiment the content of the present invention is specified:

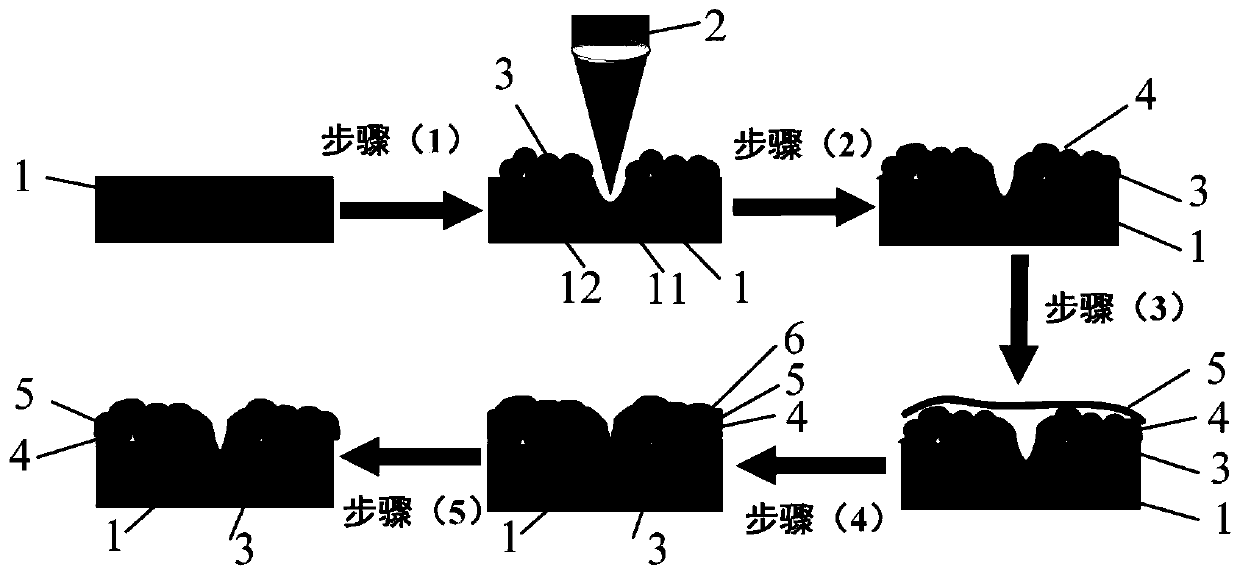

[0030] Please check figure 1 , a method for rapidly preparing a large-area graphene / metal composite structure surface-enhanced Raman scattering substrate, comprising:

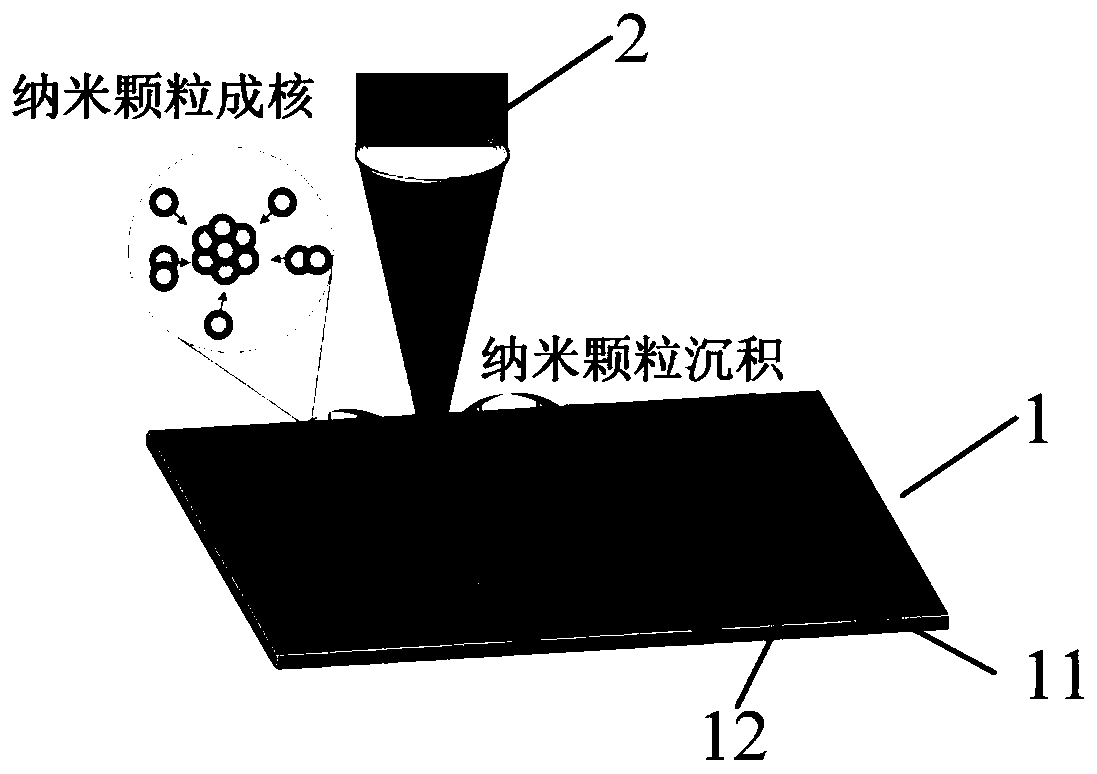

[0031] 1) if figure 2 As shown, the pulsed laser 2 is used to process a line array pattern on the surface of the substrate 1 in a linear scanning manner to form several laser processed areas and several laser unprocessed areas distributed alternately. In this embodiment, the power of the pulsed laser 2 used is 5W, the pulse width is 1ns, and the pulse repetition frequency is 100KHz. The pulsed laser 2 is driven by a scanning galvanometer to scan rapidly at a scanning speed of 100 cm / s, and focused onto the surface of the substrate 1 by an f-theta field lens. The substrate 1 is a silicon substrate, and the focused spot size at the focal point is 20 μm. The line array formed by line-scanning the focused pulsed laser 2 on the surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com